Coupling rolling wheel vibration dam material compaction quality real-time detection device and method

A compaction quality, real-time detection technology, applied in the direction of measuring devices, dams, barrages, etc., can solve problems that cannot truly reflect the compaction quality of dam materials, and achieve the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

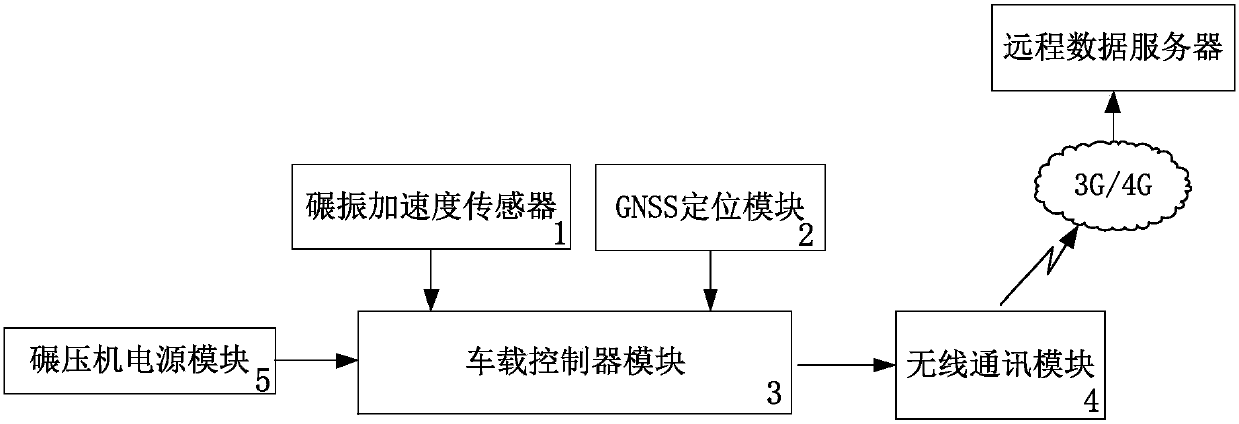

[0051] The present invention aims at overcoming the deficiencies of the existing research, aiming at the defects of the existing frequency-domain compaction indicators for detecting the compaction quality of earth-rock dams, and proposes a real-time detection device and method for the compaction quality of earth-rock dams or roller compacted concrete dams, Avoid the impact of vibration frequency on frequency domain compaction index. For this reason, the technical scheme that the present invention adopts comprises earth-rock dam or roller compacted concrete dam compaction quality real-time detection device and method, and detection device comprises: rolling vibration acceleration sensor, GNSS (Global Navigation Satellite System) positioning module, vehicle-mounted integrated controller module, There are 5 parts in total, the wireless communication module and the power module of the rolling machine, see the composition structure figure 2 .

[0052] The rolling vibration accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com