Conventional large liquid engine propellant flow field calibration system and method

An on-site calibration, propellant technology, applied in liquid/fluid solid measurement, test/calibration volume flow, test/calibration device, etc., can solve the problems of slow response speed of measurement data, increased measurement links, and many uncertain factors. , to achieve accurate and fast calibration results, improve reliability, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

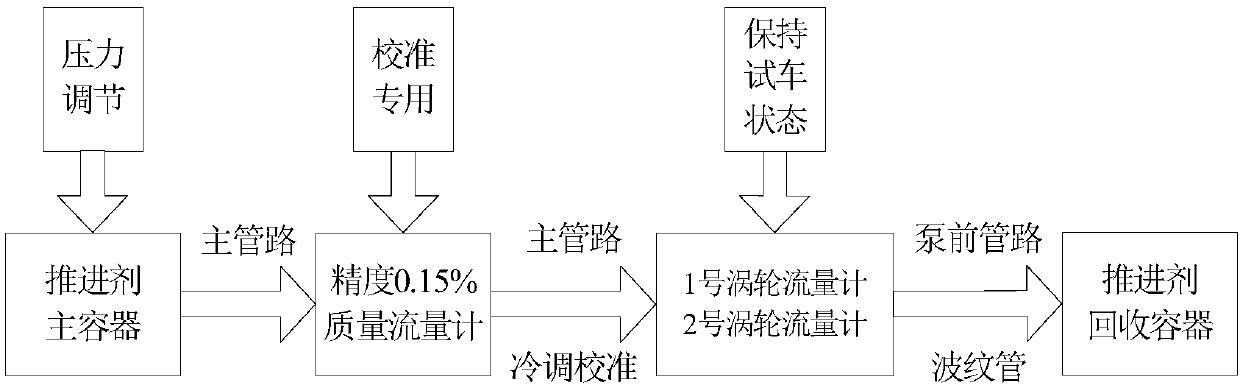

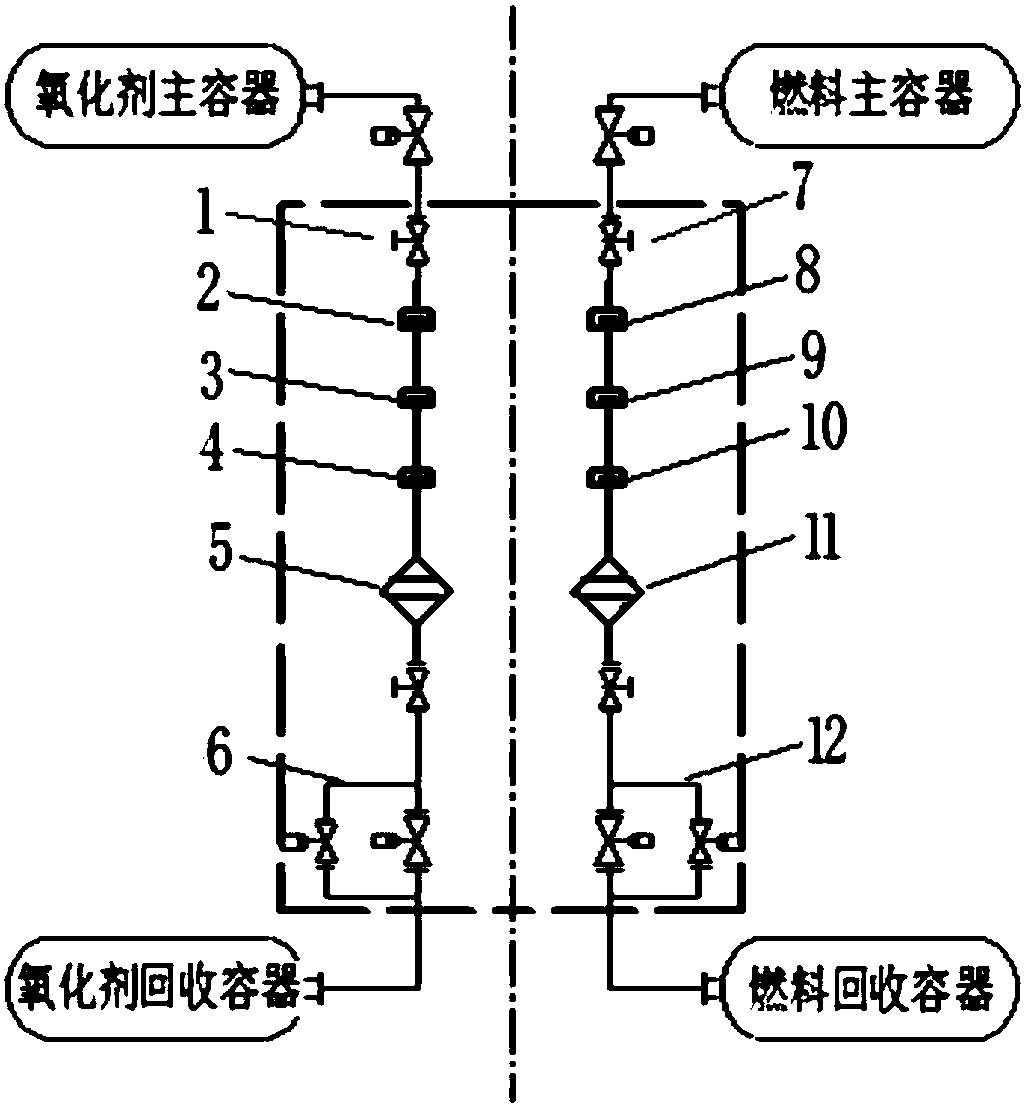

[0041] The composition principle of the test bench propellant flow field calibration system is as follows: figure 1 shown. Install a mass flowmeter in the main pipeline, configure the propellant recovery pipeline, and ensure that the position and state of the turbine flowmeter are consistent with those during the test run, and carry out the cold adjustment of the real propellant through the pressure adjustment control of the main propellant container calibration. The measurement principle of the mass flowmeter is the proportional relationship between the vibration frequency of the measuring tube inside the flowmeter and the mass flow rate of the fluid. Considering the continuity and consistency of the flow measurement state of the test bench and the influence of vibration and noise during the test run of the large engine, during the test run interval period, according to The number and frequency of test runs, regularly use the mass flowmeter to cool the real medium of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com