Power battery pack with heat superconducting heat exchanger and power battery pack system

A power battery pack, thermal superconductivity technology, applied in the direction of batteries, secondary batteries, battery temperature control, etc., to achieve high reliability, compact and flexible structure, and improve the effect of heating start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

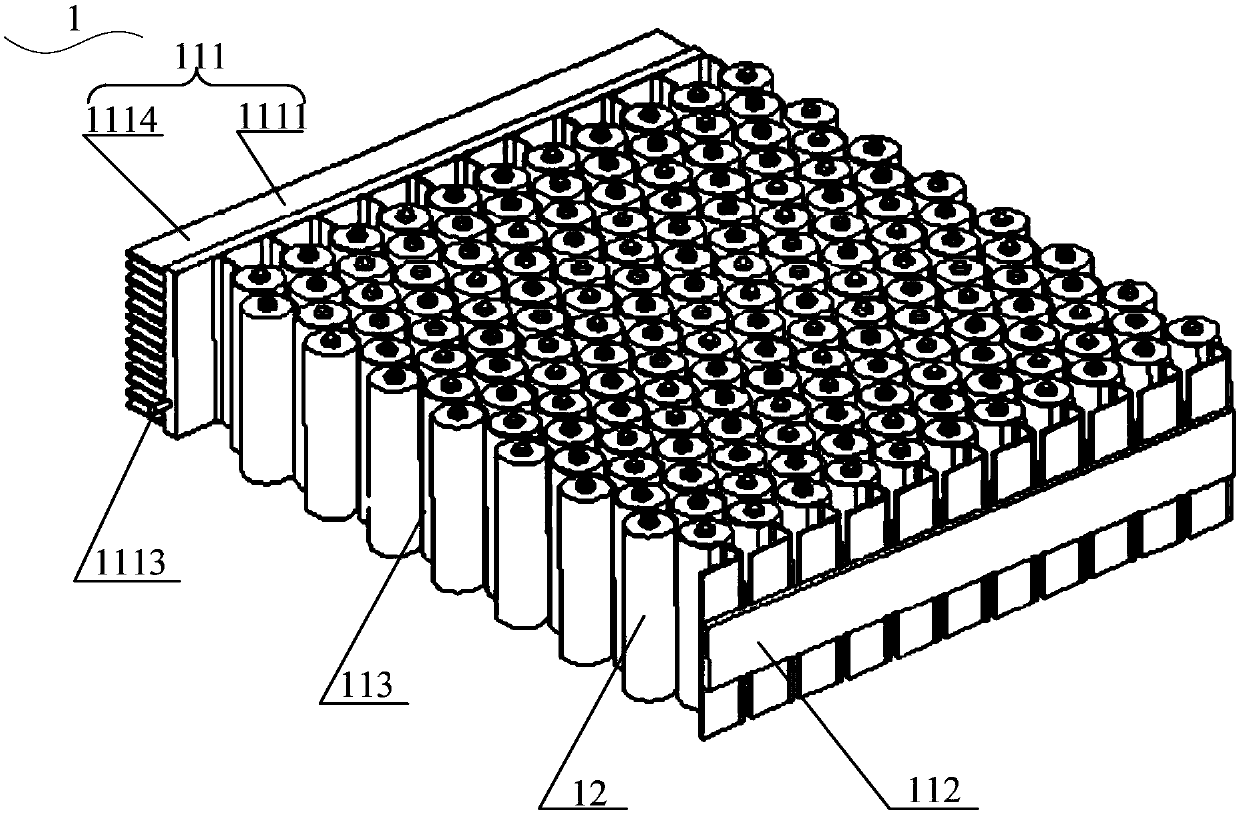

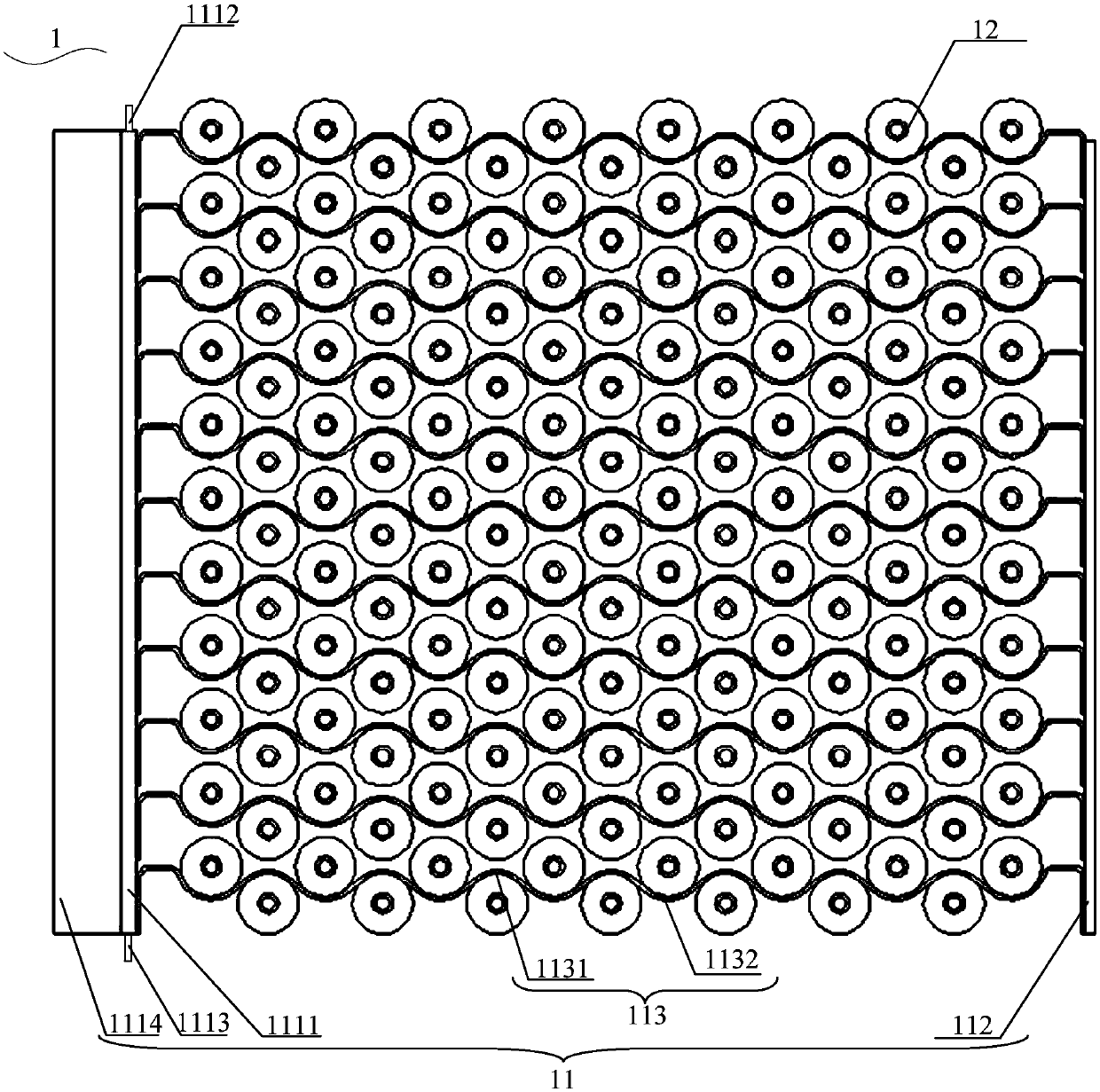

[0081] see Figure 1 to Figure 9 , the present invention provides a power battery pack 1 with a thermal superconducting heat exchanger, and the power battery pack 1 with a thermal superconducting heat exchanger includes: a thermal superconducting heat exchanger 11 and several battery cells 12; Wherein, the thermal superconducting heat exchanger 11 includes a radiator 111, a heater 112 and several thermal superconducting plates 113 arranged in parallel at intervals; the heater 112 is located on one side of the radiator 111, and The radiator 111 has a spacing; the thermal superconducting plate 113 is located between the radiator 111 and the heater 112, one end of the thermal superconducting plate 113 is connected to the radiator 111, and the other end is connected to the radiator 111. The heater 112 is connected, and a thermal superconducting circuit 1136 is formed in the thermal superconducting plate 113 (such as Figure 4 to Figure 7 shown), the thermal superconducting pipeli...

Embodiment 2

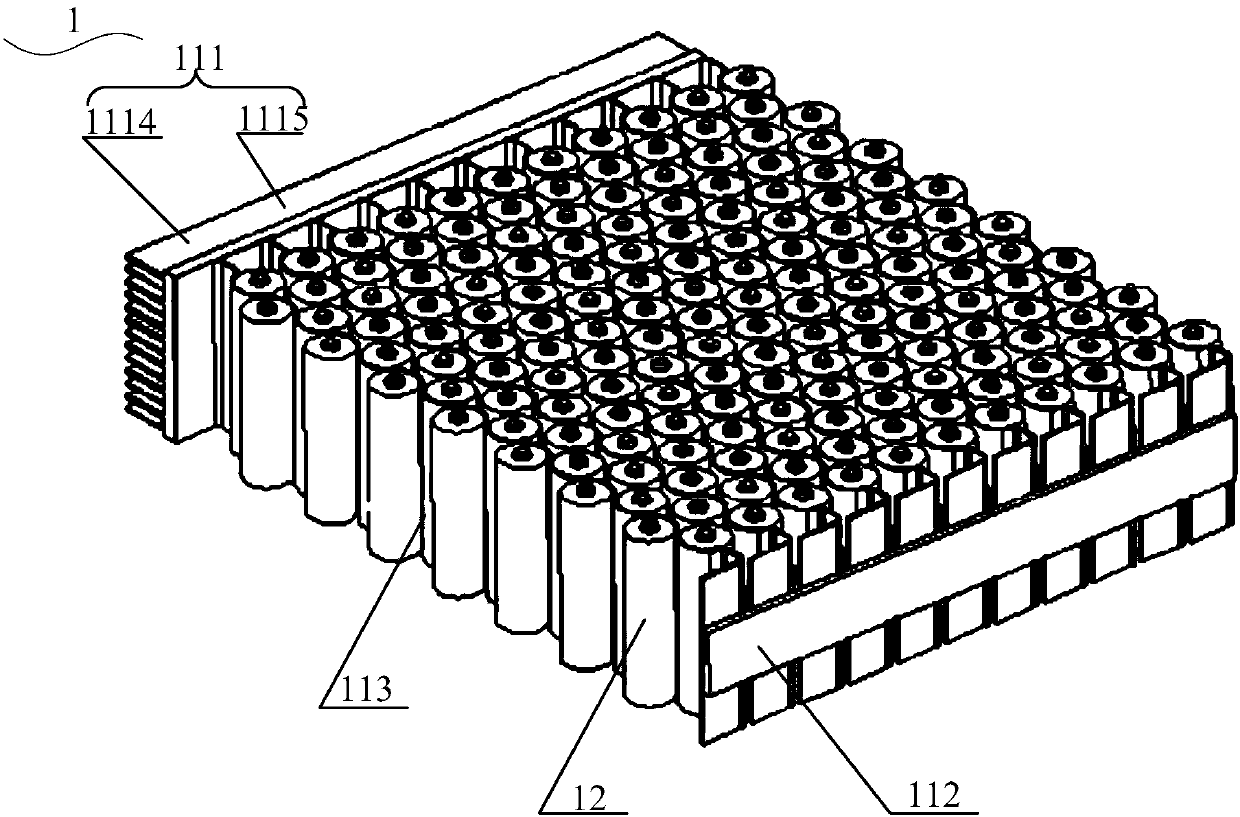

[0105] see Figure 10 to Figure 12The present invention also provides a power battery pack 1 with a thermal superconducting radiator. The structure of the power battery pack 1 with a thermal superconducting radiator described in this embodiment is the same as that described in Embodiment 1 with a thermal superconducting The structure of the power battery pack 1 of the conduction heat sink is roughly the same, the difference between the two is: in the first embodiment, the thermal superconducting plate 1313 includes a wave portion 1131 and a bending portion 1132; wherein, the wave portion 1131 includes an opposite The first surface and the second surface of the wave portion 1131 also include a plurality of first raised portions 11311 raised toward the first surface and second raised portions 11312 raised toward the second surface. The protruding parts 11311 and the second protruding parts 11312 are alternately distributed along the length direction of the thermal superconductin...

Embodiment 3

[0109] see Figure 13 , the present invention also provides a power battery pack system, the power battery pack system includes: the power battery pack 1 with a thermal superconducting heat exchanger as described in Embodiment 1 or Embodiment 2; a refrigerant system, the The refrigerant system at least includes a refrigerant source 2, which is used to provide refrigerant to the radiator 111; a heating controller 3, which is connected to the heater 112, and is used to control the operation of the heater 112 .

[0110] As an example, when the radiator 111 is a structure including the cooling plate 1111 and the cooling fins 1114, the refrigerant source 2 may be a cooling water source or a cooling air source, and the refrigerant system further includes a refrigerant supply pipe Road 21 and a refrigerant discharge pipeline (not shown), one end of the refrigerant supply pipeline 21 is connected to the refrigerant source 2, and the other end is connected to the inlet of the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com