High-efficiency energy-saving plastic sealing motor and mounting method thereof

A plastic-encapsulated motor, high-efficiency and energy-saving technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as accumulated moisture, increased motor power consumption, and expansion of internal components, reducing energy consumption and power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

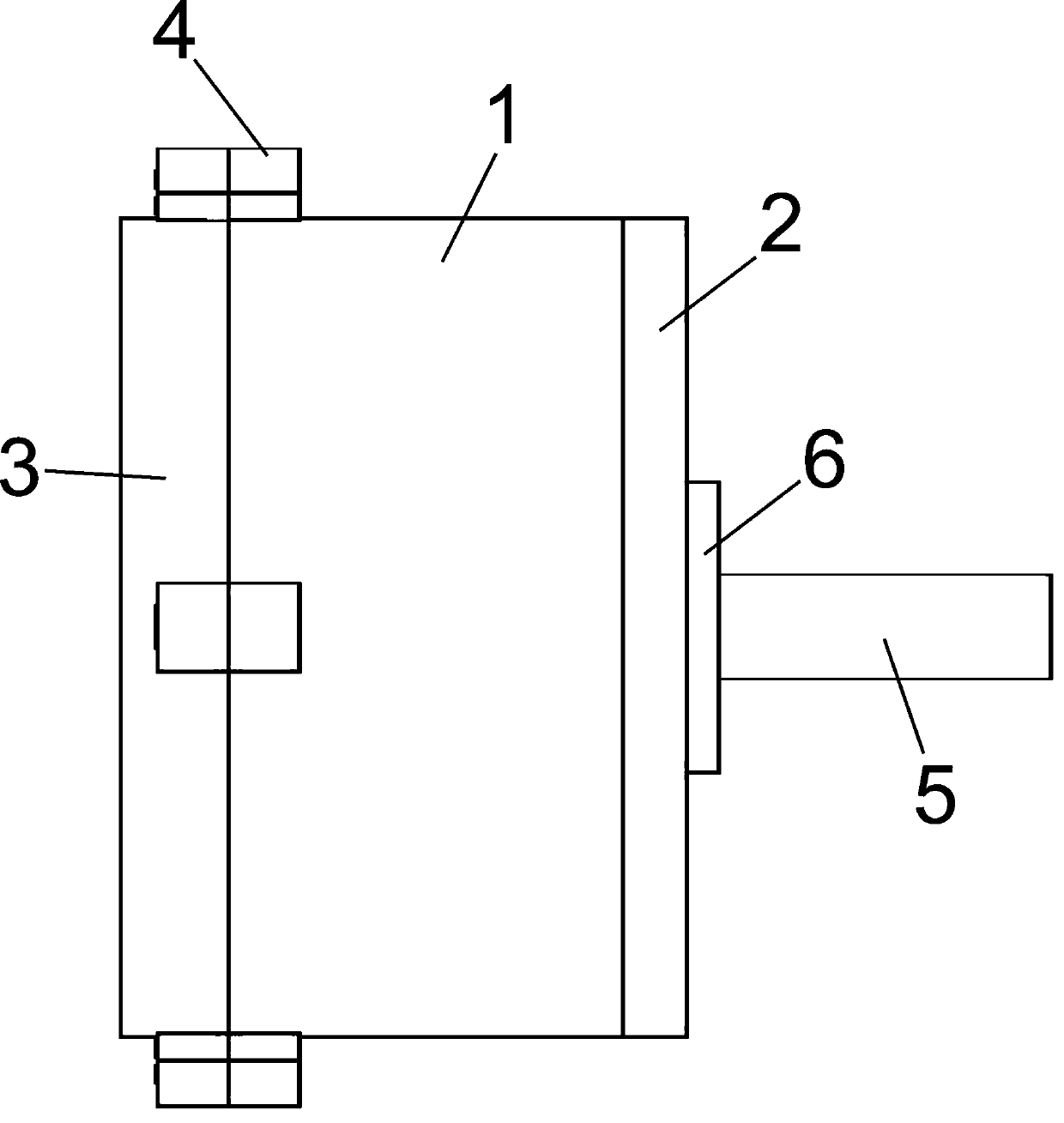

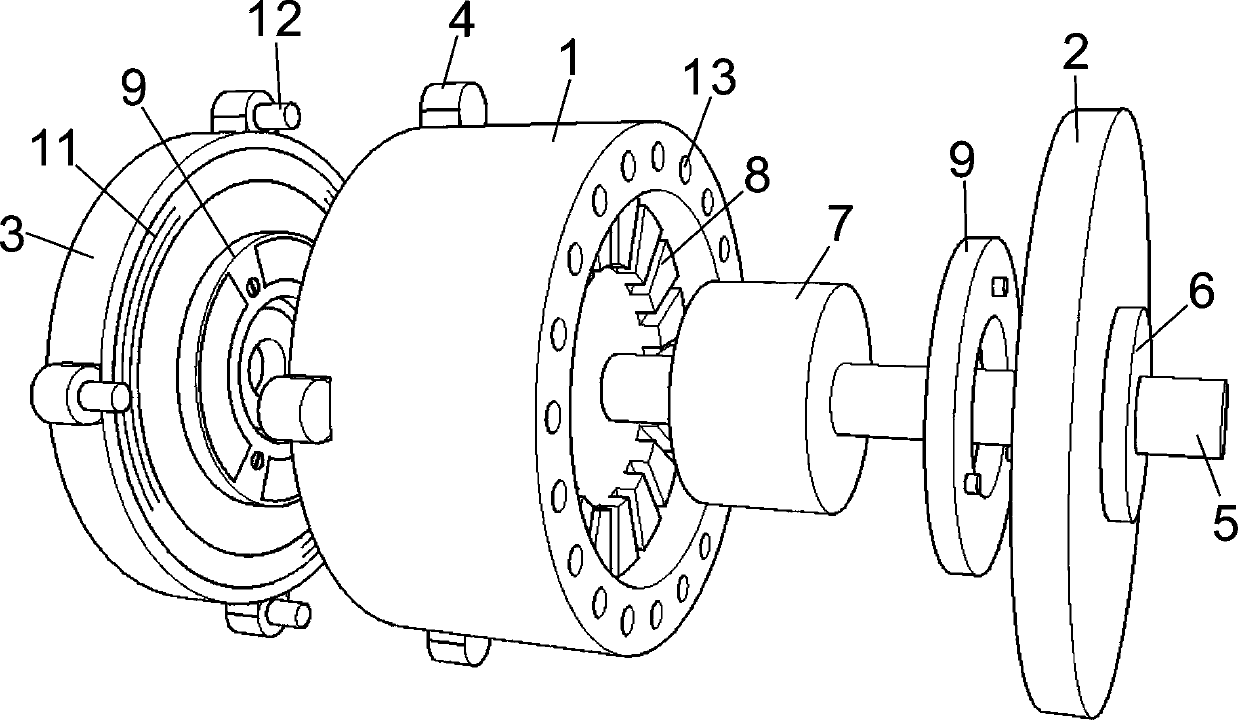

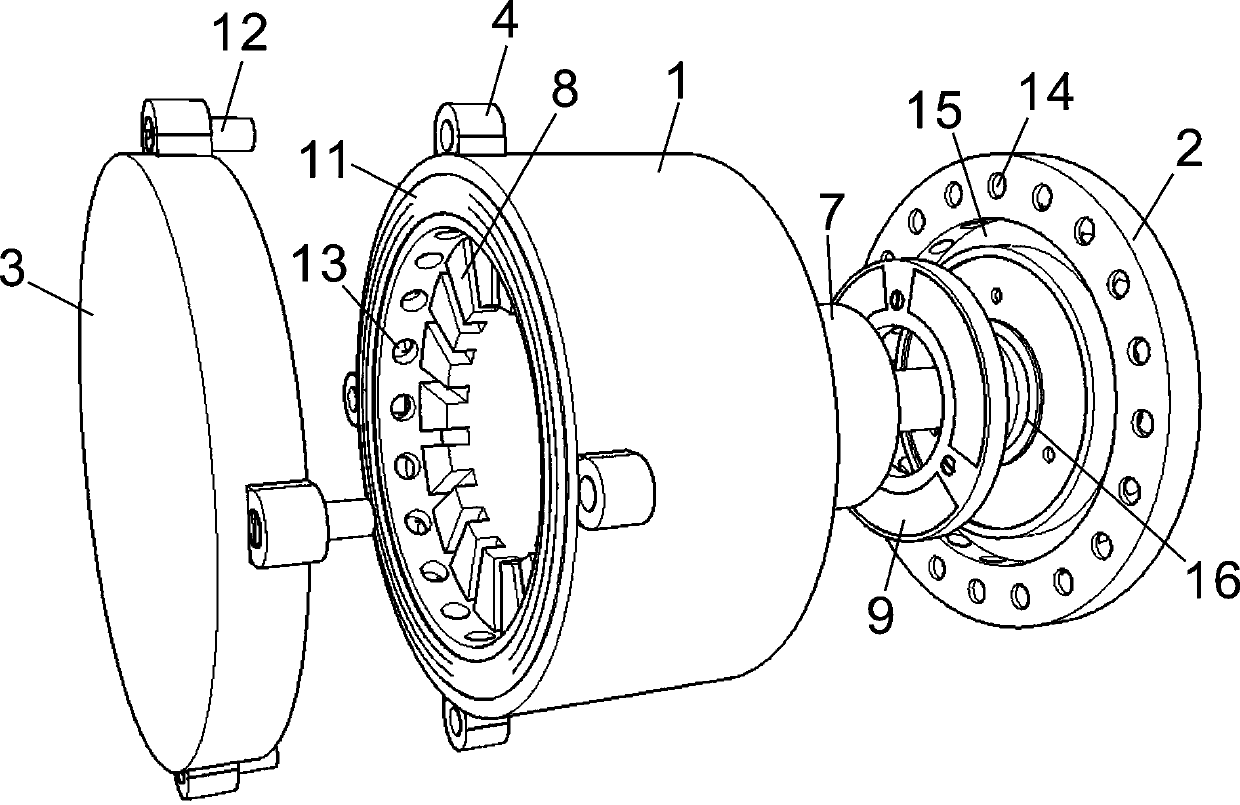

[0021] As shown in the figure, a high-efficiency energy-saving plastic-sealed motor and its installation method include a middle plastic-sealed body 1, a rear end cover 3, a fixed ear 4, a rotating shaft 5, a rotor 7, and a stator 8, wherein the rear end of the middle plastic-sealed body 1 is provided with a rear end The cover 3 is provided with fixed ears 4 on the middle plastic package body 1 and the rear end cover 3, the rear end cover 3 is installed on the middle plastic package body 1 by fixing bolts 12, and the stator 8 is fixedly arranged in the middle plastic package body 1, and the rotor 7 is fixedly installed with the rotating shaft 5, and the rotor 7 is installed in the middle part of the middle plastic package body 1. The front end of the middle part plastic package 1 is provided with a front end cover 2, and the front end cover 2 is bonded with the middle part plastic package 1 as a whole. In production, the rear end surface of the front end cover 2 and the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com