Hydraulic machine control and management method and system with cloud platform function

A technology for control management and hydraulic presses, applied in transmission systems, digital transmission systems, services based on specific environments, etc., which can solve problems such as the inability of hydraulic presses to save working parameter data in real time, the inability to understand the working conditions of hydraulic presses in time, and the inconvenience of production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

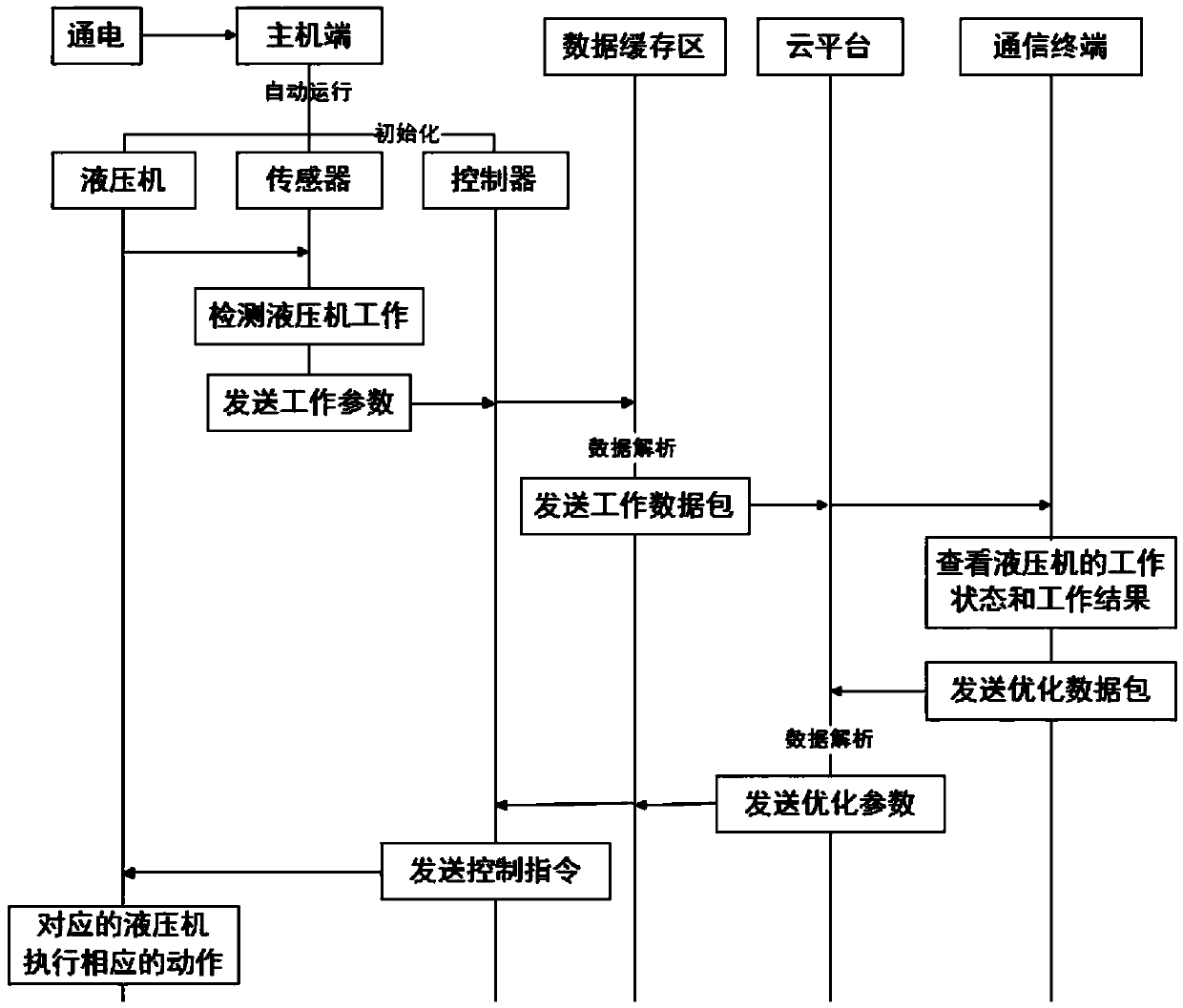

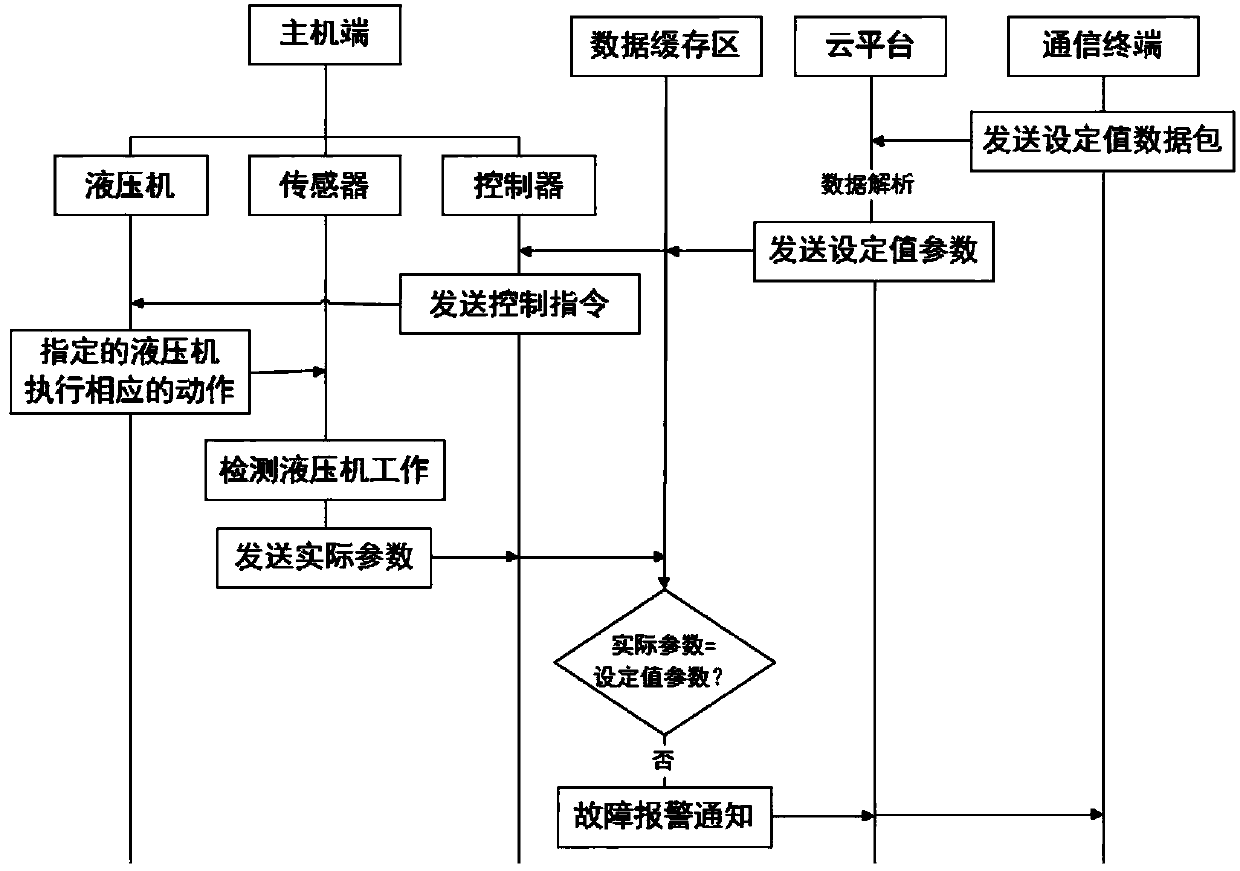

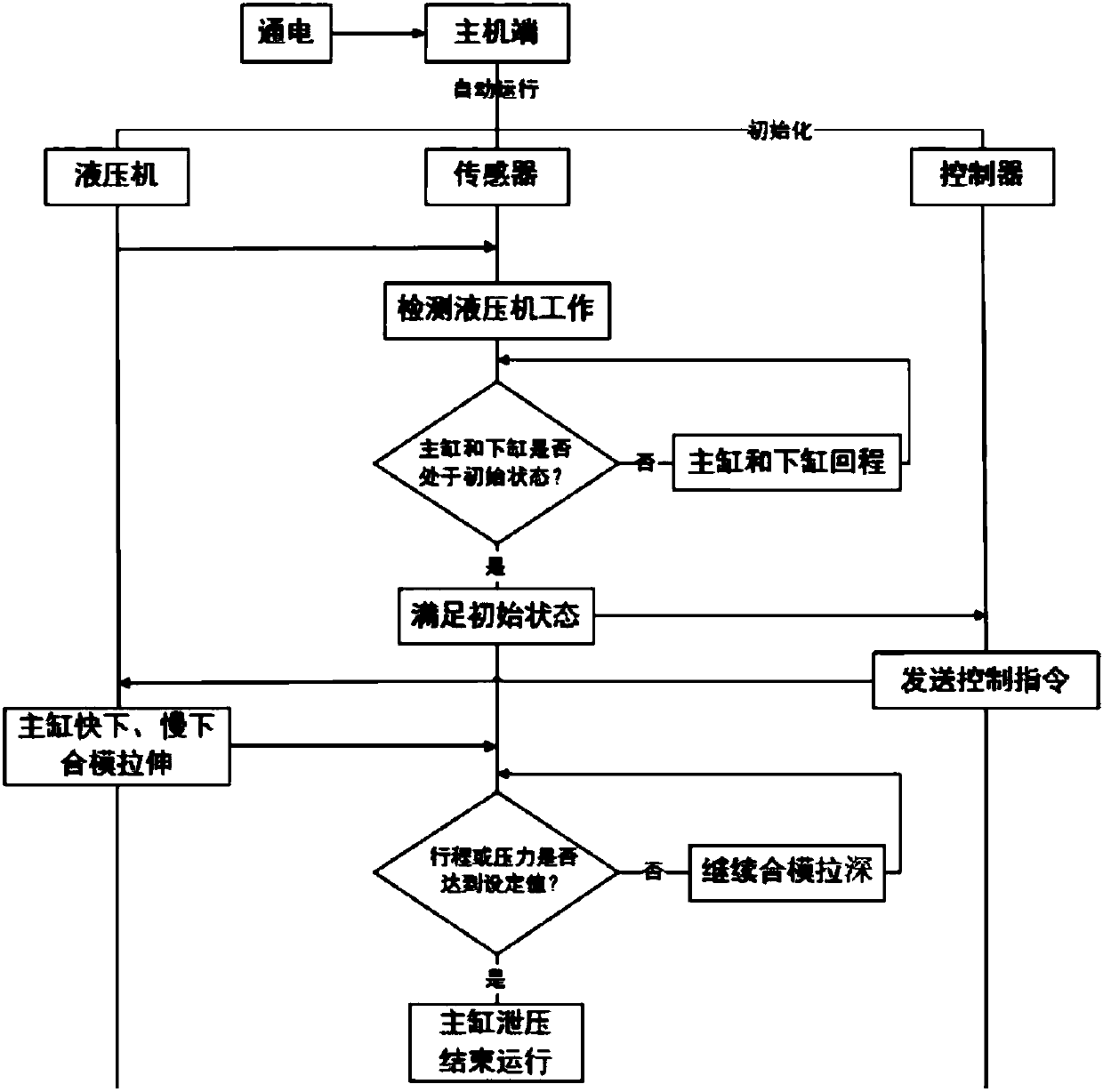

[0058] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0059] A method for controlling and managing a hydraulic machine with a cloud platform function, comprising a cloud platform 1, a host terminal 2 and a communication terminal 3, the host terminal 2 and the communication terminal 3 are respectively connected to the cloud platform 1 through a wireless communication network; the host terminal 2 includes a hydraulic machine 20, a controller 21 and a sensor 22; including the following control and management steps at the host end 2:

[0060] Step A1, power on the host terminal 2 and initialize the data of the controller 21, press the automatic operation button, and the host terminal 2 starts to operate automatically;

[0061] Step A2, the sensor 22 detects the working status and working results of one or more hydraulic machines 20, analyzes the working pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com