Deep well gravity ice conveying and streaming guiding type rapid and controllable ice melting device and method

A flow-guided, ice-transporting technology, which is applied in earth cube drilling, ventilation of mines/tunnels, mining equipment, etc., can solve problems such as shortage, and achieve the effects of accelerated melting, novel and reasonable design, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

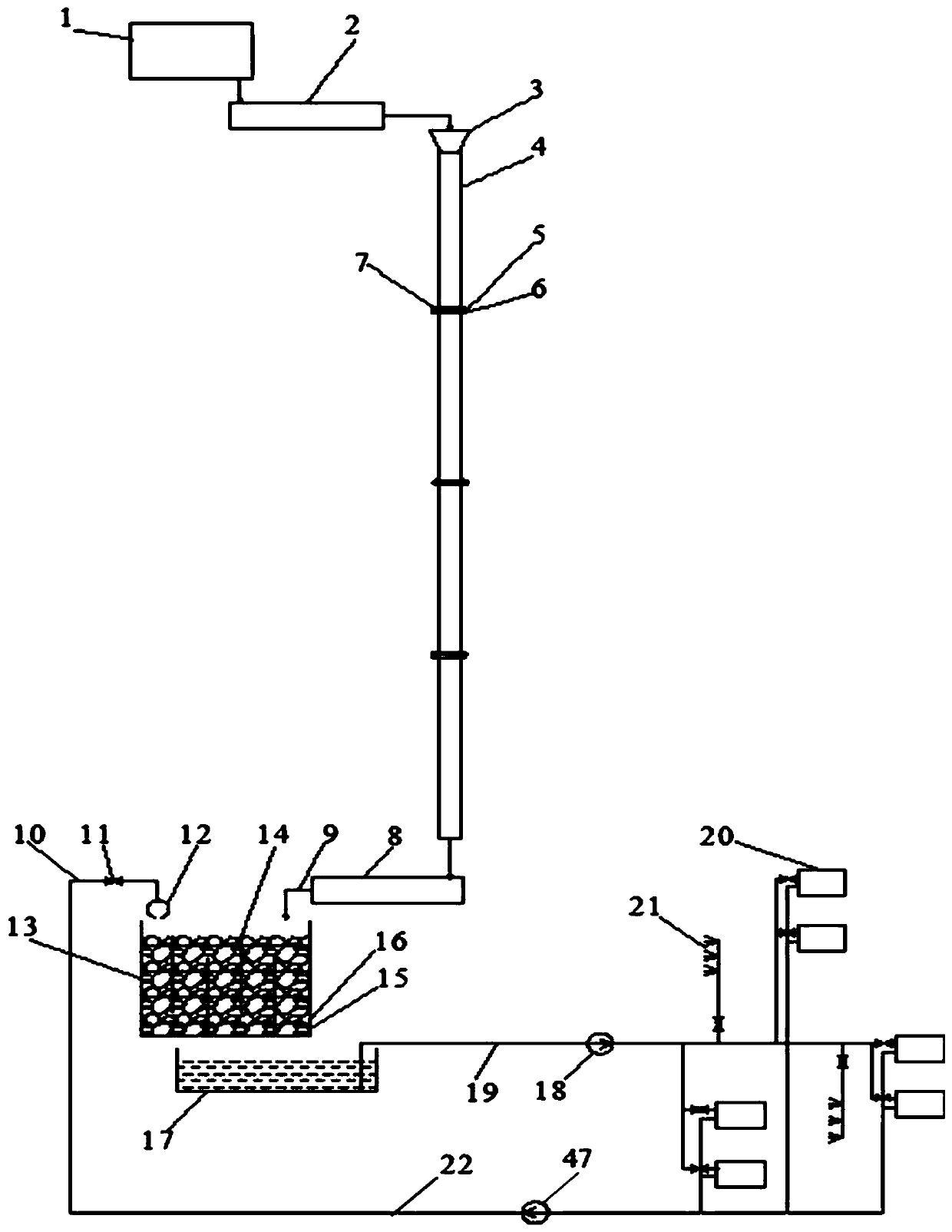

[0071] Such as Figure 1 to Figure 7 As shown, the deep well gravity ice conveying and circumvention-guided rapid and controllable ice melting device of this embodiment includes a ground ice maker 1, a ground ice conveying device 2, a gravity ice conveying mechanism, an underground ice conveying device 8 and an underground ice melting device. device, the ground ice delivery device 2 is connected to the ground ice machine 1;

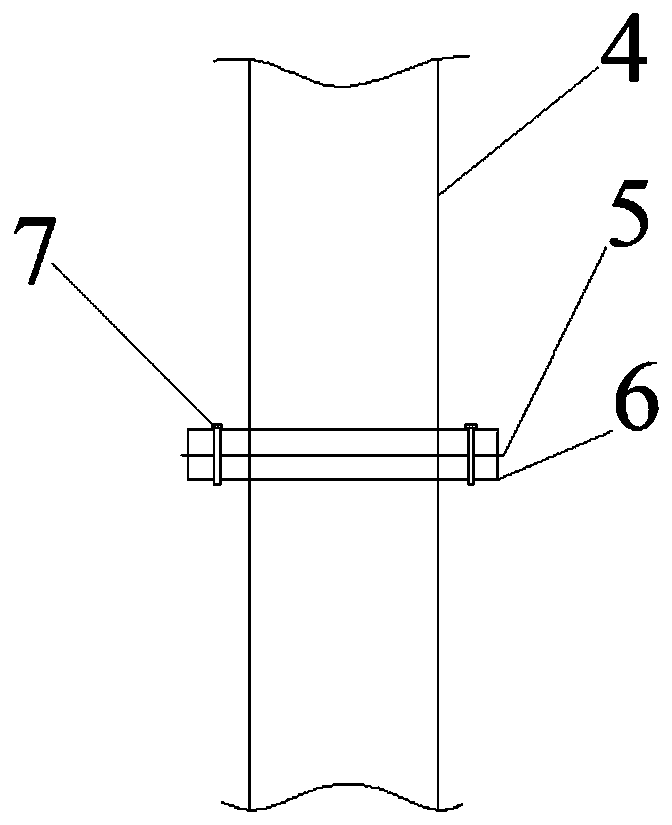

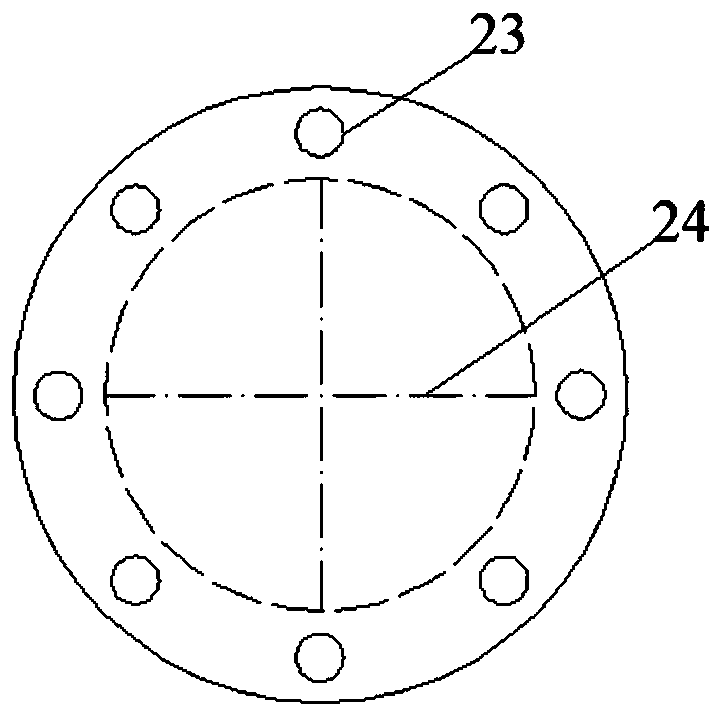

[0072] The gravity ice delivery mechanism includes a wellhead funnel 3 and a multi-section shaft ice delivery pipeline 4 connected to the bottom of the wellhead funnel 3 and extending into the deep well. Buffer rubber gaskets 5 are arranged between the pipes 4, and the bottom end of a vertical shaft ice transportation pipeline 4 located at the lowermost end of the deep well is connected to the downhole ice transportation device 8;

[0073] The underground ice-melting device comprises an ice-melting pool 13, an ice-melting pool ice inlet pipe 9 arranged o...

Embodiment 2

[0089] The deep well gravity ice transporting and circumventing guide type rapid and controllable ice melting device of this embodiment is different from Embodiment 1 in that it also includes an automatic control and monitoring system, such as Figure 8 As shown, the automatic control and monitoring system includes a data acquisition controller 45 and a computer 46 connected to the data acquisition controller 45. The input terminal of the data acquisition controller 45 is connected with the temperature of the working face arranged on the underground mining face. The sensor 28, the cold water tank temperature sensor 29 and the cold water tank level sensor 30 arranged in the cold water tank 17, the ice melting tank liquid level sensor 31 arranged in the ice melting tank 13, are arranged on the water inlet pipe 10 of the ice melting tank 13 The ice-melting tank inlet water temperature sensor 32 and the ice-melting tank inlet water flow sensor 33, the air cooler inlet water tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com