Discharge tube

A discharge tube and discharge active technology, which is applied in the field of discharge tubes, can solve the problems of large distance between the discharge trigger film and the coating film, the change of working voltage, and the deviation of working voltage, so as to reduce the scattering of the discharge active layer, stabilize the working voltage, and suppress the change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

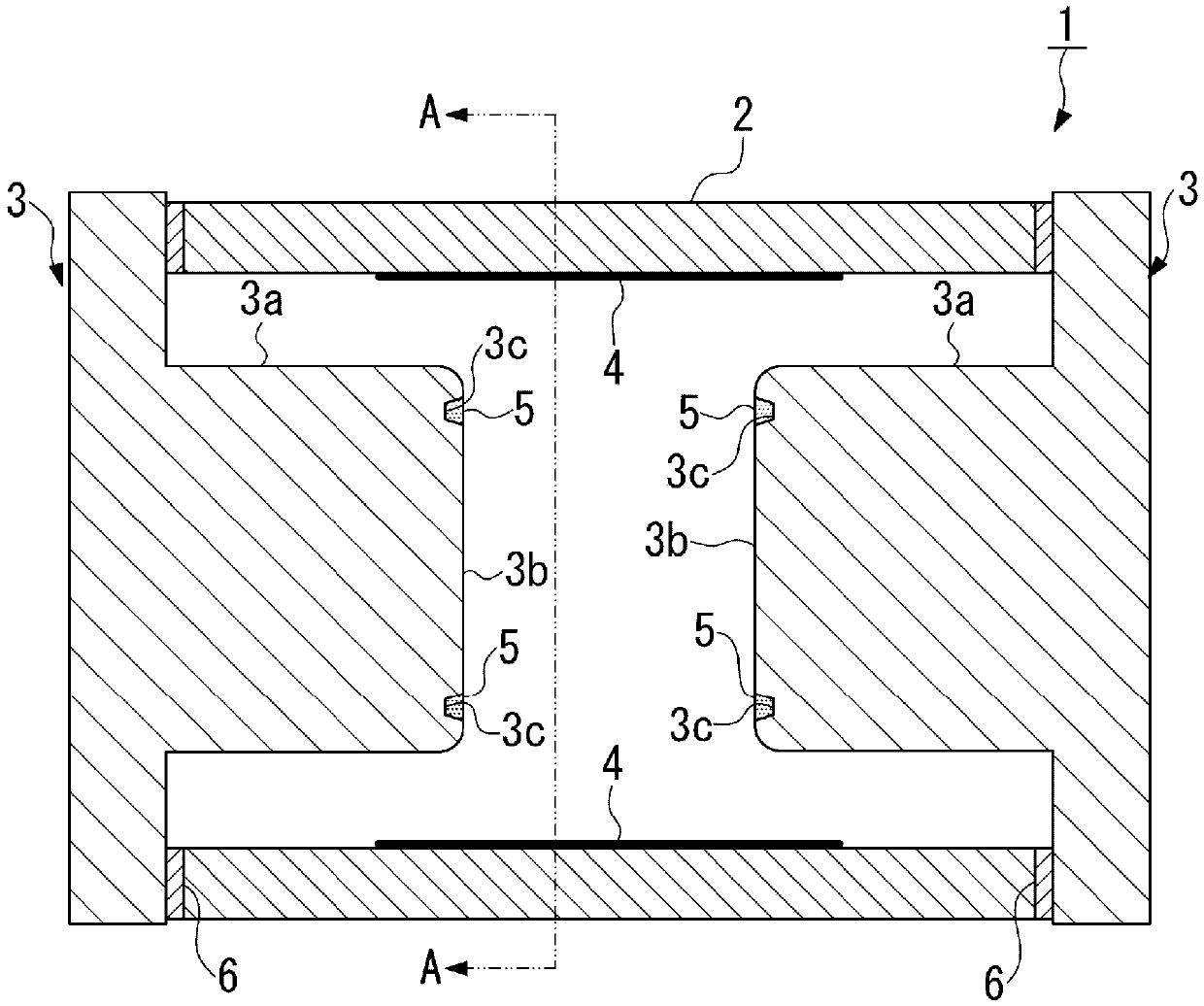

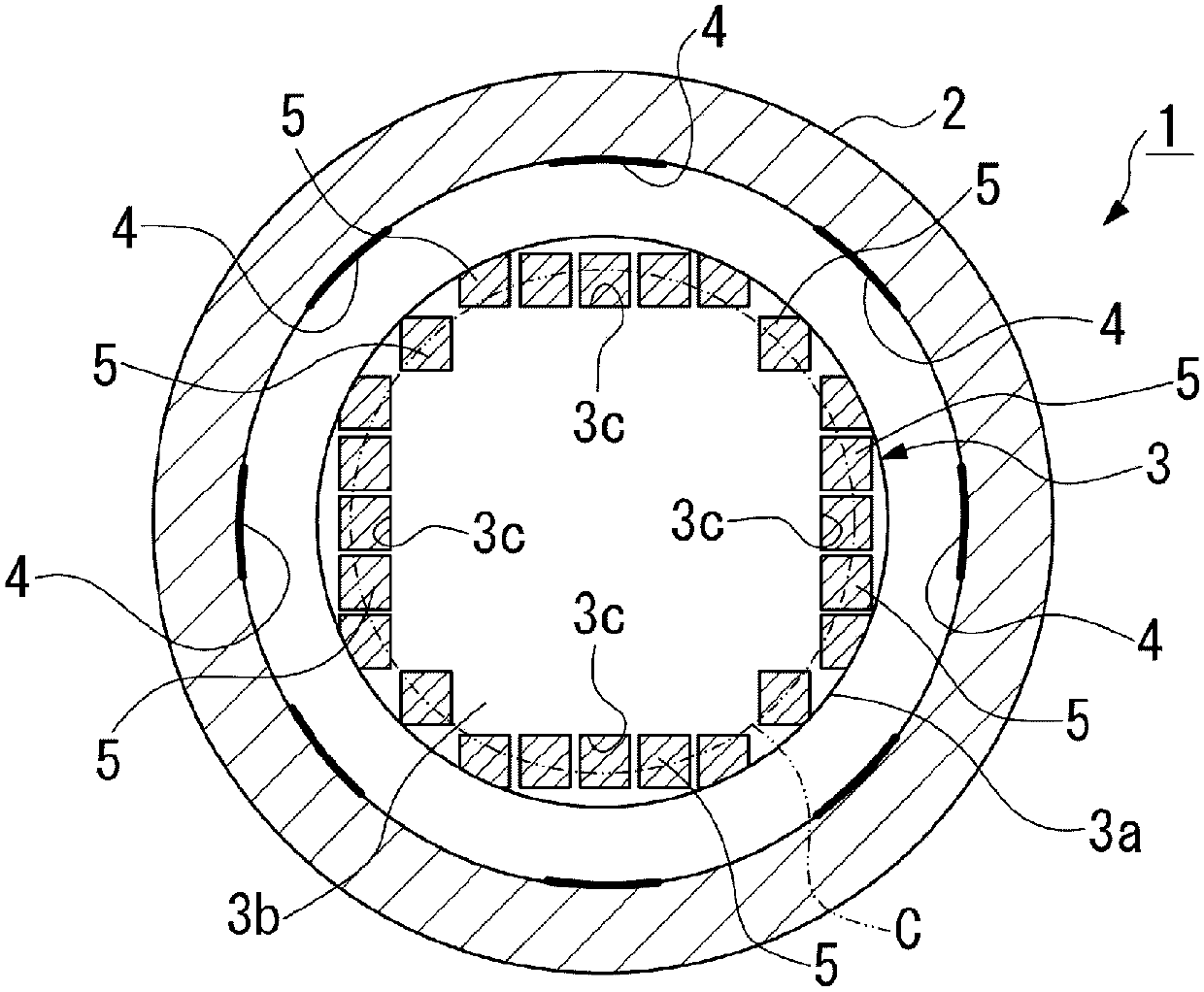

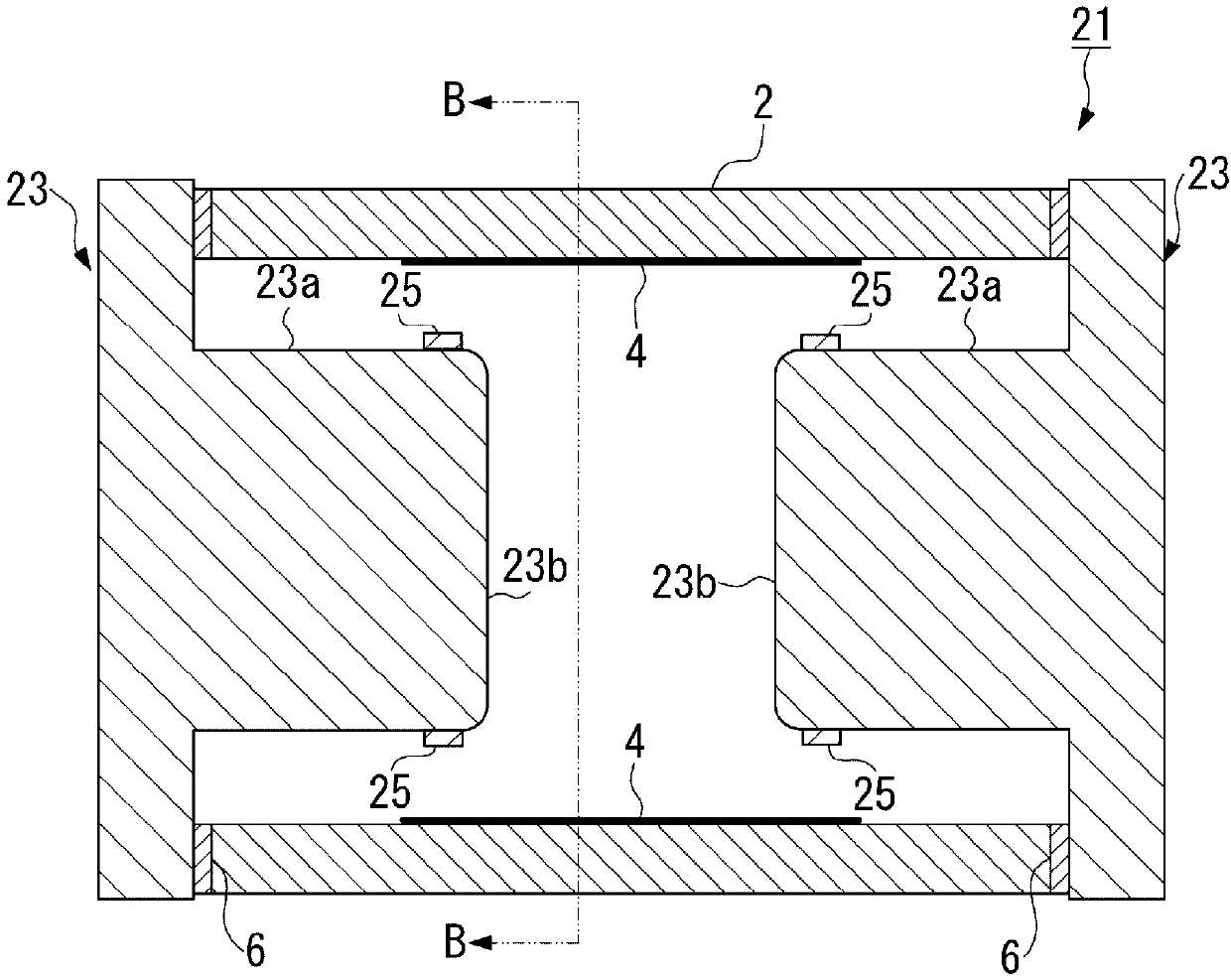

[0058] Next, regarding the embodiments of the present invention, refer to Figure 6 to Figure 8 , the electrical characteristics (discharge characteristics) of the gas arrester (discharge tube) in which the discharge active layer is formed on the surface of the sealing electrode will be described.

[0059] As examples of the present invention, the discharge tube described in the above-mentioned first embodiment was produced as Example 1, and the discharge tube described in the above-mentioned second embodiment was produced as Example 2.

[0060] In addition, in the preparation of samples for evaluation of electrical characteristics, insulating hollow bodies and sealing electrodes of the same size were used, and the discharge control gas, pressure, and gas sealing procedures filled in the gas arrester were also set the same. Furthermore, the discharge initiation voltage of each sample was made the same at 350 V, and the factors other than the formation position of the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com