Efficient particle processing device for aquatic feed for large yellow croakers

A technology for aquatic feed and processing equipment, applied in the direction of feed, application, food science, etc., can solve the problems of low granulation efficiency, granulation waste, and quantitative weighing, etc., to improve speed and output, increase granulation speed, Effect of increasing granulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

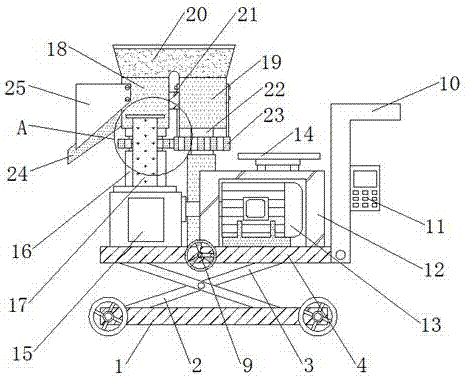

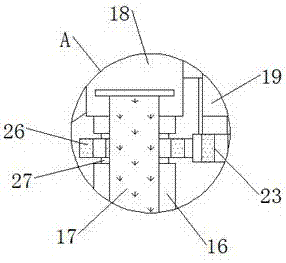

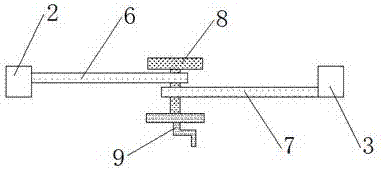

[0027] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a high-efficiency pellet processing device for aquatic feed of large yellow croaker, comprising a fixed seat 1, the top of the fixed seat 1 is connected with a first pole 2, and the top of the fixed seat 1 is located at the second The outer side of a pole 2 is connected with a second pole 3, and the top ends of the first pole 2 and the second pole 3 are installed inside the support platform 4, and the interior of the fixing seat 1 and the support platform 4 corresponds to the first pole 2 and the position of the second pole 3 are provided with a chute 5, the middle part of the front end of the support table 4 is connected with a hand handle 9, and the inside of the support table 4 corresponding to the inner side of the hand handle 9 is connected with a rotating rod 8, the first The top of a pole 2 is positioned at the inside of the support platform 4 and is connected with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com