A method for emptying a three-head line distributor and an oil-water separation barrel

A technology of oil-water separation and splitter, which is applied in the field of oil and gas, can solve the problems of damage to the flow meter of the fuel dispenser, the threat to the safety of the gas station, and the delay of emptying work, and achieve the effects of reducing discharge loss, good sealing performance, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

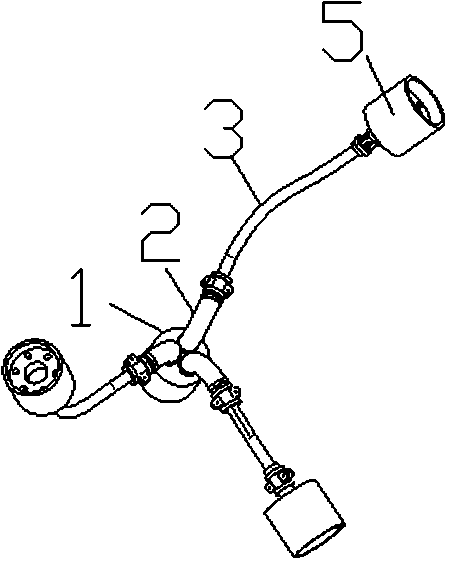

[0023] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0024] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

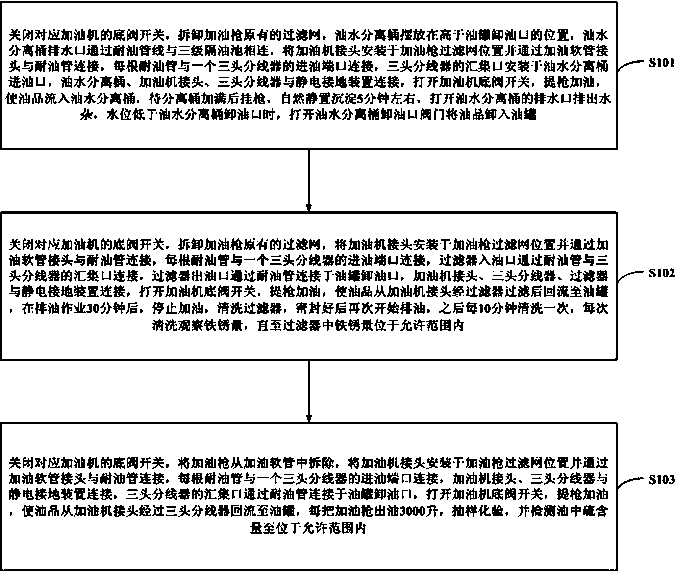

[0025] A method for emptying the three-head splitter and the oil-water separation barrel includes:

[0026] S101. Close the bottom valve switch of the corresponding fuel dispenser, remove the original filter screen of the fuel gun, place the oil-water separation barrel at a position higher than the oil discharge port of the oil tank, and the drain of the oil-water separation barrel passes through the oil-resistant pipeline and the three-stage grease trap Connected, install the refueling machine connector at the position of the filter screen of the refueling gun and connect it to the oil-resistant pipe through the refueling hose conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com