A kind of high-performance liquid potting composition and application

A composition and high-performance technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of low refractive index, low hardness, poor heat resistance, etc., and achieve the effect of high refractive index and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the high-performance liquid potting composition includes the following steps: weighing each component according to the formula; mixing epoxy resin, adhesion strengthening agent, ultraviolet absorber, transparent purple-blue paste and defoaming Stir the agent at 80-90°C to obtain component A; stir the acid anhydride curing agent, curing accelerator and antioxidant at 60-70°C to obtain component B; stir components A and B to obtain liquid Potting composition.

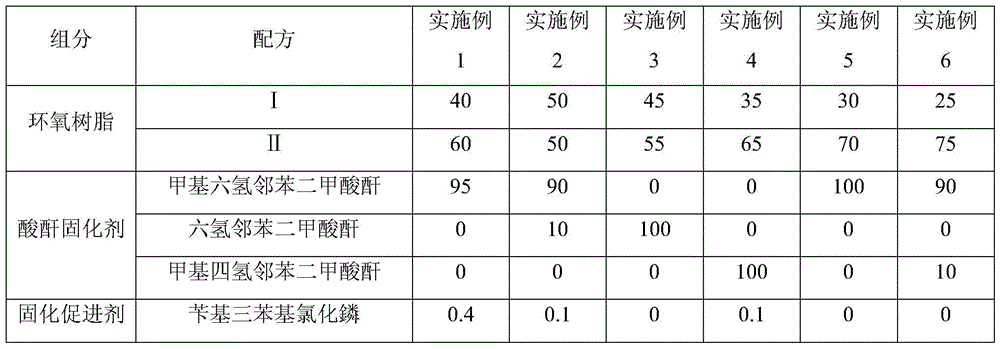

[0043] The formulations of the liquid potting compositions of Examples 1-6 are shown in Table 1.

[0044] Table 1 The formula of embodiment 1-6 liquid encapsulation composition

[0045]

[0046]

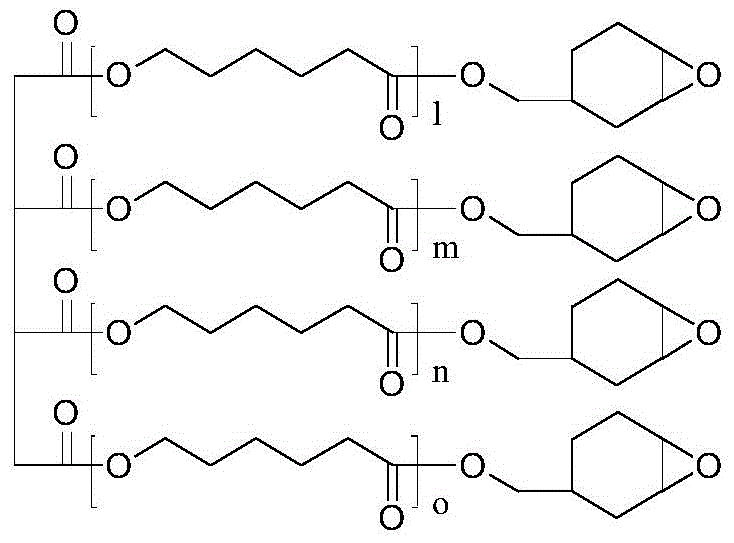

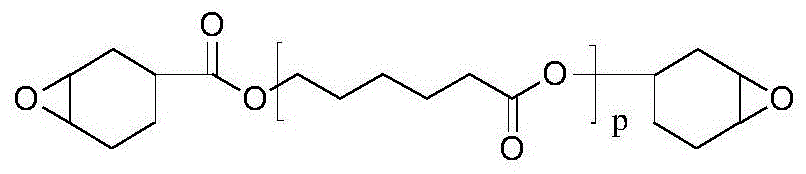

[0047] Among them, the carboxylic acid cycloaliphatic epoxy resin shown in the structural formula I adopts the aliphatic epoxy resin EPOLEADGT401, and the basic indicators: the epoxy equivalent is 220, and the viscosity is 2300mPa.s / 70°C; the carboxylic acid shown in the structural formula I...

Embodiment 1

[0050] Example 1 The preparation method of the liquid potting composition: In a 1L four-necked flask, add 40 parts by weight of the carboxylic acid cycloaliphatic epoxy resin represented by the structural formula I and 60 parts by weight of the carboxylic acid lipid represented by the structural formula II Cyclic epoxy resin, 0.4 parts by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 0.01 parts by weight of transparent purple-blue paste, 1.0 parts by weight of polyvinyl butyral, 0.2 parts by weight of defoamer, Stir evenly at 80-90°C to obtain a transparent component A; in a 1L four-necked flask, add 95 parts by weight of methylhexahydrophthalic anhydride, 0.4 parts by weight of benzyltriphenylphosphonium chloride, and 0.5 parts by weight One part of 2,6-di-tert-butyl-4-methylphenol, stirred at 60-70°C to obtain a transparent B component; A and B components were stirred at room temperature for 15 minutes at a high speed to obtain a uniform liquid Potting composition.

Embodiment 2-6

[0051] Examples 2-6 Refer to Example 1 for the preparation of the liquid potting composition.

[0052] The properties of the liquid potting compositions and their cured products prepared in Examples 1-6 were investigated.

[0053] The viscosity of the liquid potting composition before curing was measured using a rotational viscometer.

[0054] Using 1 g of the liquid potting composition, use a gelation time tester to test the gelation time of the liquid potting composition before curing.

[0055] The refractive index of the liquid potting composition before curing was measured using an Abbe refractometer.

[0056] The liquid potting composition is cured at 120°C / 1 hour, and then cured at 130°C / 1 hour, and the performance of the cured liquid potting composition is evaluated:

[0057] The glass transition temperature Tg was determined by using DSC to raise the temperature twice at a rate of 10°C / min between 30°C and 250°C in an air atmosphere.

[0058] According to the GBT934...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com