Adjustable-type casting floating and rotating mechanism

A technology of rotating mechanism and floating mechanism, which is applied in the direction of machine tools, grinding racks, and grinding workpiece supports suitable for grinding the edge of workpieces. It can solve the problems of non-adjustable height, low production efficiency, and high labor intensity. Prevent external forces from interfering with the movement of the shaft, improve production efficiency, improve stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

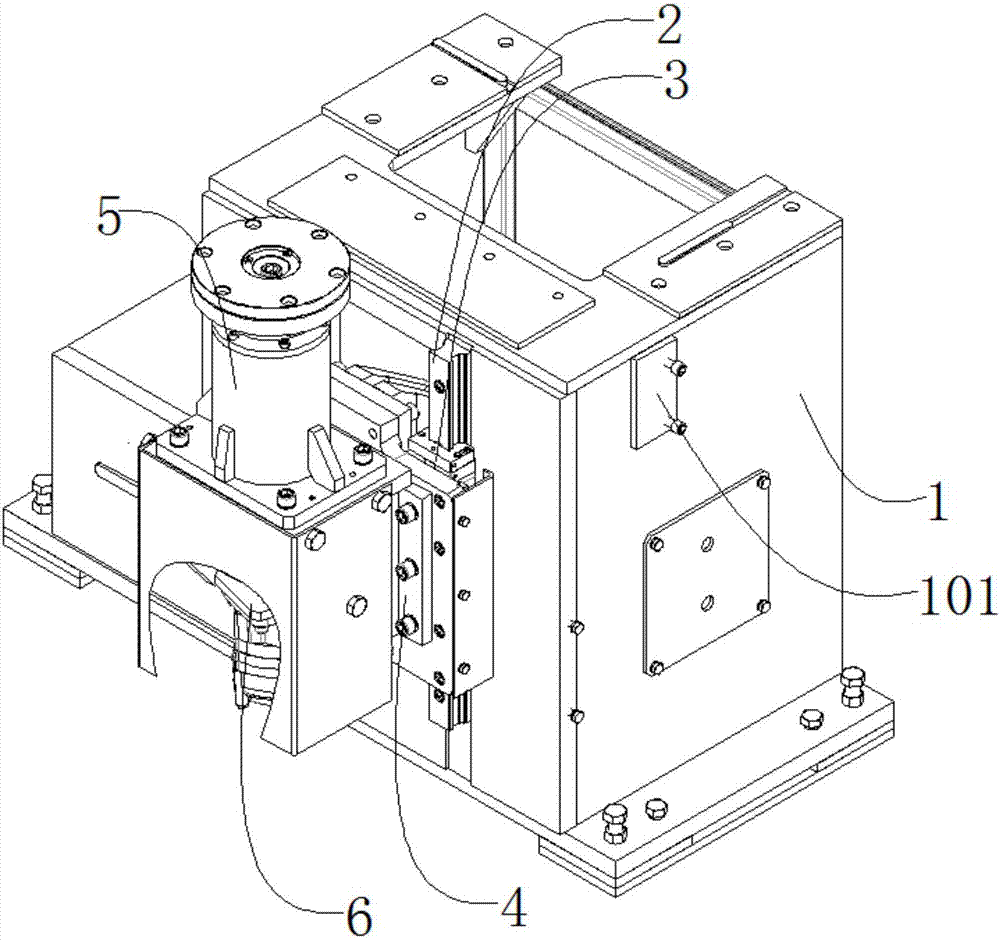

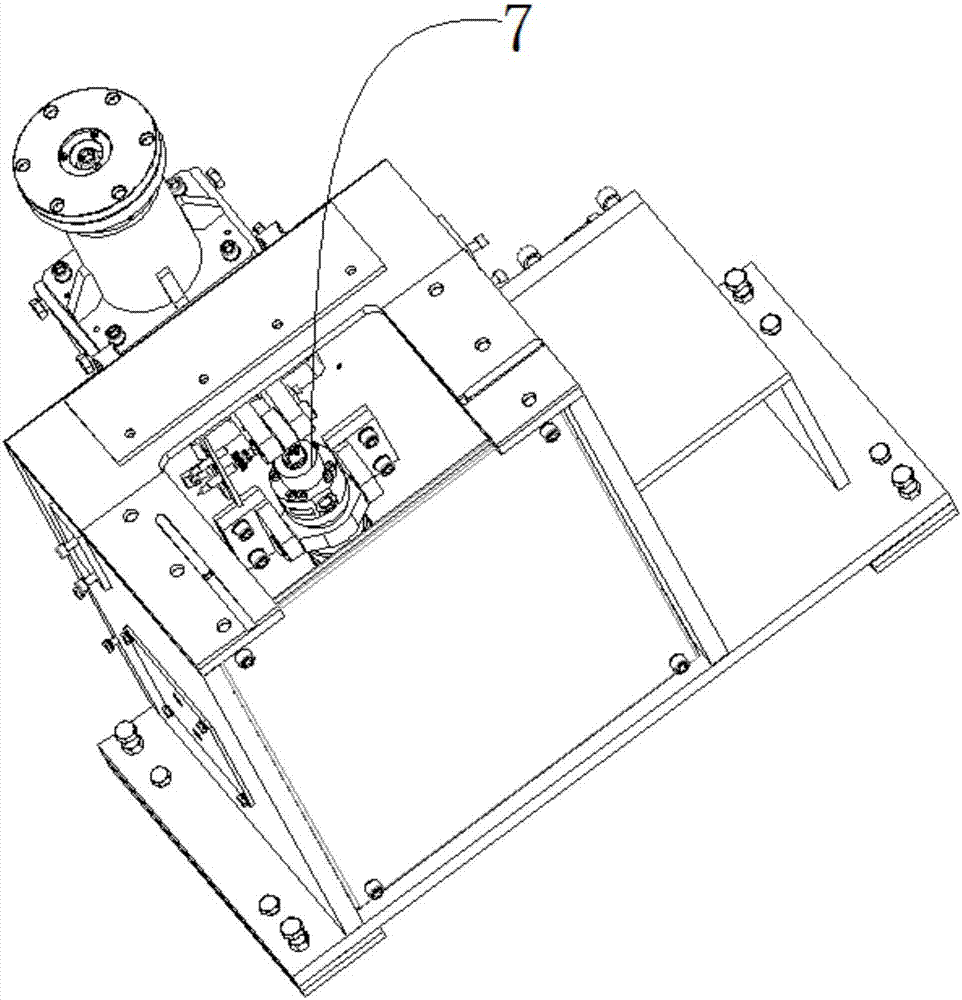

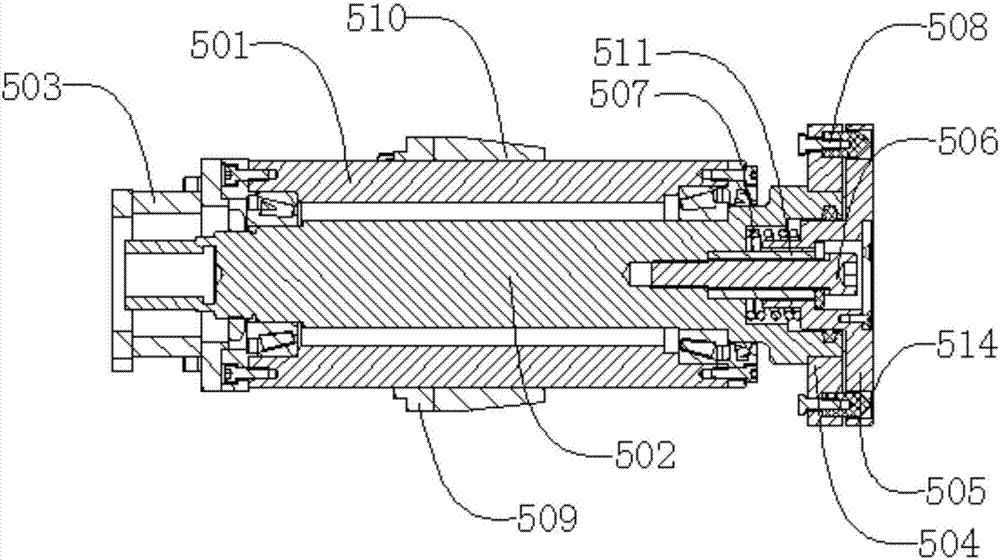

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, an adjustable casting floating rotation mechanism includes a frame 1, a guide rail 2, a slider 3, a sliding plate 4, a floating mechanism 5, a speed regulating motor 6, and an adjustment mechanism 7. The guide rail 2 is located on the frame 1 On the outside, the guide rail 2 is connected with the frame 1 by bolts, the guide rail 2 runs through the slider 3, the slider 3 can move up and down along the guide rail 2, and the slide plate 4 is located outside the slider 3, The sliding plate 4 is connected to the slider 3 by bolts, the floating mechanism 5 is located outside the sliding plate 4, the floating mechanism 5 is connected to the sliding plate 4 by bolts, and the speed regulating motor 6 is located on the floating mechanism 5 lower end, the speed-regulating motor 6 is connected with the floating mechanism 5 by bolts, the adjusting mechanism 7 is located inside the frame 1 and on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com