Light path packaging module of narrow-linewidth fiber laser

A fiber laser and packaging module technology, applied in the direction of laser cooling device, laser components, structure/shape of active medium, etc., can solve the problems of integrated packaging, phase shift grating packaging and heat insulation difficulties, etc., to achieve volume reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

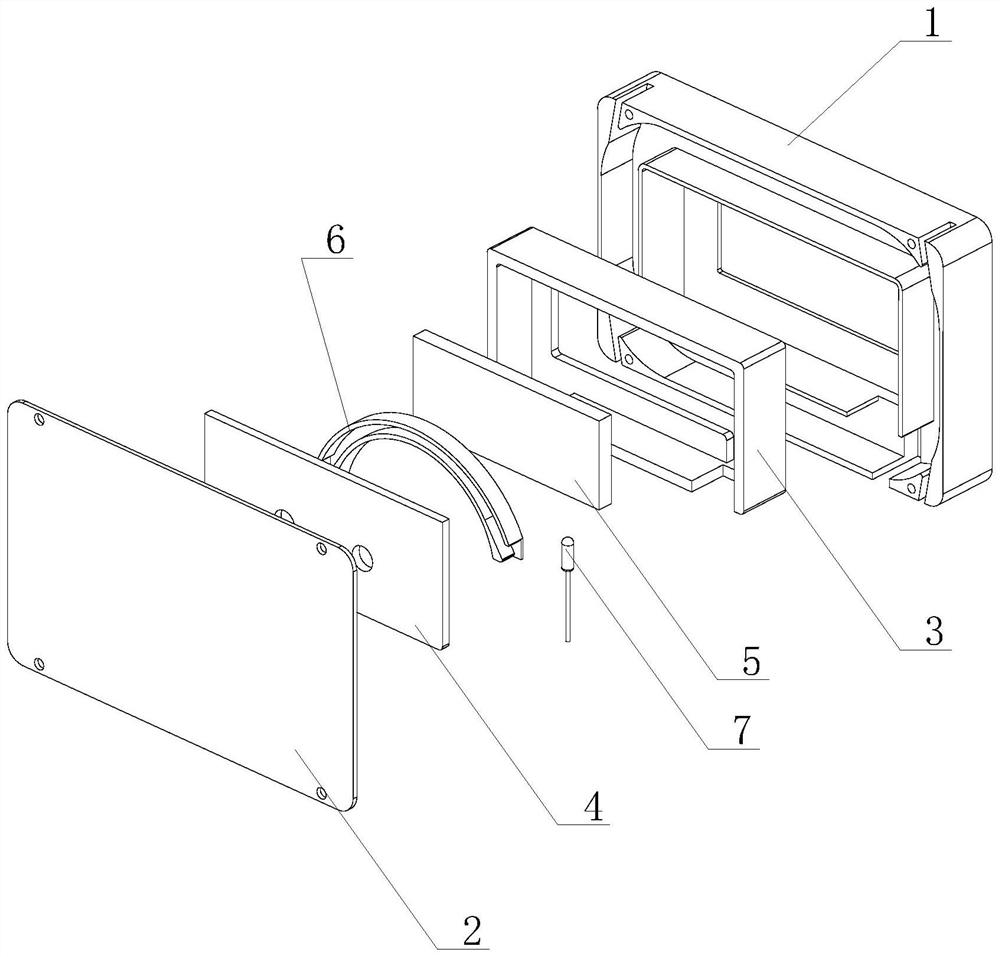

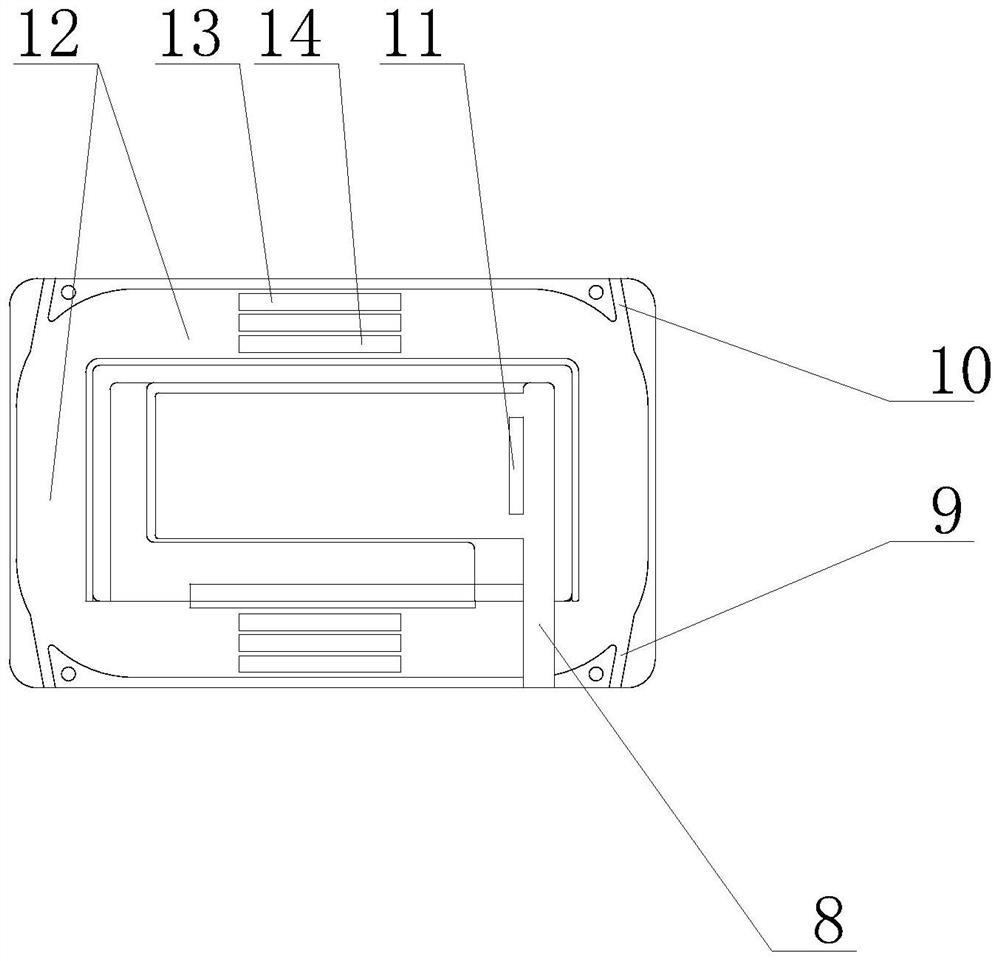

[0025] Append figure 1 , 2 As shown, a narrow line width fiber laser optical path package module includes a light path package housing 1 and a optical path package module 2, and an optical path package outer casing 1, a thermal circuit package outer casing 1, a heat insulating sheet 3 and a heat insulating sheet cover 4. The heat insulating sheet 3 and the heat insulating sheet are provided between the semiconductor refrigerator 5, the phase shift grating package structure 6 and the thermistor 7, the heat-insulating plate 3 and the heat insulating sheet. On one side of the cover 4 is provided with a trace passage 8 for the semiconductor refrigerator 5, the phase shift grating package structure 6 and the thermistor 7, and the optical path package housing 1 side portion is provided with a detachment 9 and the fiber port. 10.

[0026] In this embodiment, the finite plate 11 is provided on the side of the semiconductor cooling device 5 in order to fix the semiconductor refrigerator 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com