Fuel nozzle spray cone angle automatic measuring device

A fuel nozzle and spray cone angle technology, which is applied in the field of aero-engines, can solve the problems of low degree of automation, inability to truly reflect the real performance of fuel nozzles, poor precision, etc., to achieve strong applicability, ensure measurement accuracy, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

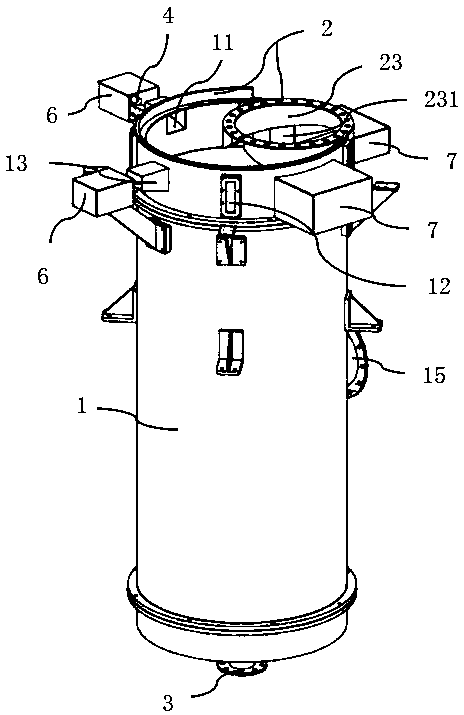

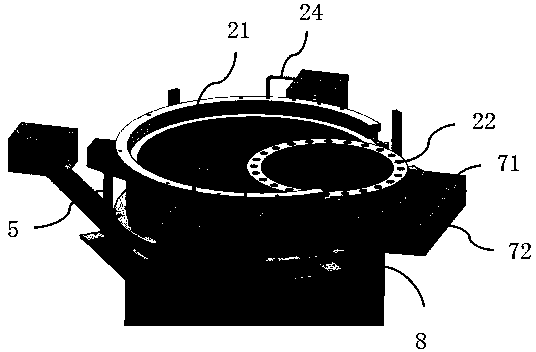

[0033] Provide an automatic measuring device for the spray cone angle of the fuel nozzle, such as figure 1 and figure 2 As shown, it includes a spray chamber 1, the first open end of the spray chamber is provided with a fixture 2 for installing fuel nozzles, and the second open end is an oil return hole 3, and the fixture 2 can make the fuel nozzle under test at the center of the first open end The side wall of the first opening end of the spray chamber 1 is provided with two through holes 11, and one of the through holes is set at a position where the overall situation of the cone angle formed by the fuel nozzle spraying out of the fuel nozzle can be spied on. The CCD camera 4 of angle, on the side wall of the spray chamber, also be evenly distributed with a plurality of transparent plates 12, on the spray chamber 1 outer wall, the light source 5 that can illuminate the spray cone angle place is supported by the supporting structure at each transparent plate setting position...

Embodiment 2

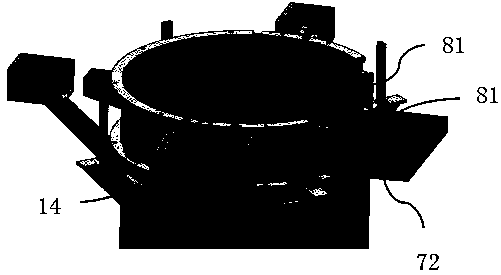

[0048] The difference between this embodiment and embodiment 1 is: the test fixture is a single nozzle fixture, such as Figures 6 to 8 As shown, a single nozzle fixture includes a disc 25 fitted to the first open end and a nozzle installation hole 26 in the center of the disc, and the disc and the nozzle installation hole are connected by a plurality of ribs 27 .

[0049] In order to enhance the versatility of the spray chamber, generally, the spray chamber is uniformly selected as the spray chamber structure described in Embodiment 1. At this time, in order to make the spray chamber also suitable for assembling with a single nozzle fixture, it is necessary to make a single nozzle fixture. Simple structural changes, at this time, a part of the darkroom also needs to be set on the single nozzle fixture, that is, the darkroom is formed by combining the upper half and the lower half, and the upper half is fixed on the outer periphery of the fixture disc. The upper half of the dar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com