Horizontal displacement control device and method of formwork in hollow floor slab

A technology of horizontal displacement and hollow-core slabs, which is applied in the direction of floors, building components, buildings, etc., can solve the problems that the spacing of hollow structures of hollow-core slabs does not match the design, the thickness of concrete does not match the design, and affects structural safety, etc., so as to improve the utilization rate of steel bars , low cost, and the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

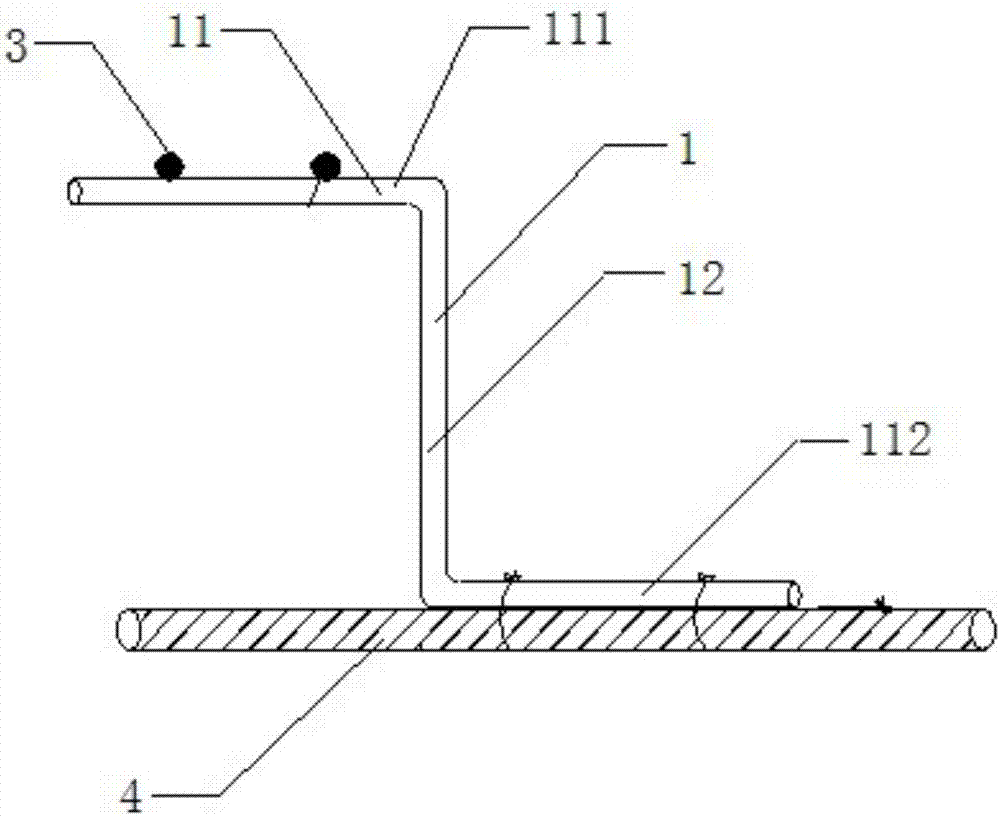

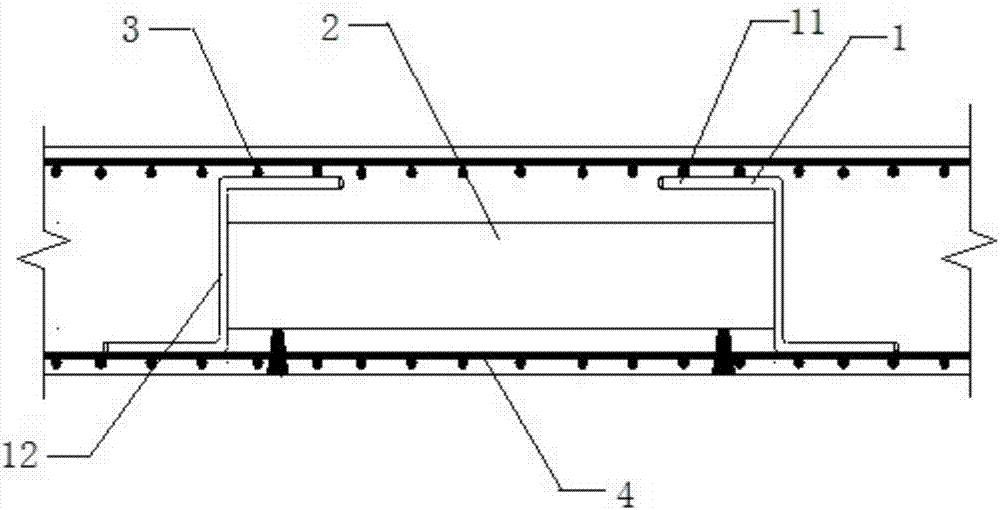

[0026] Such as figure 1 , figure 2 As shown, the formwork horizontal displacement control device in a hollow floor slab described in this embodiment includes several horizontal displacement control structures 1, and the horizontal displacement control structure 1 includes a fixing part 11 and a formwork limit part 12, and the formwork limit The position part 12 is arranged on the side of the formwork 2, and the formwork limit part 12 is connected with the fixed part 11, and the fixed part 11 is fixed with the upper layer steel bar 3 or the lower layer steel bar 4 of the floor. Before pouring the hollow floor slab, use the horizontal displacement control device to fix the position of the formwork 2. During pouring, the formwork is subjected to unbalanced side pressure. Due to the horizontal displacement control device fixing the formwork 2, it will not move in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com