Limiting element for heating cigarette and preparation method of limiting element

A component and position-limiting technology, which is applied in the field of heating cigarette limit components, can solve problems such as displacement and insufficient smoke release, and achieve the effects of good heat resistance, restriction of sheet displacement, and stable and sufficient release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

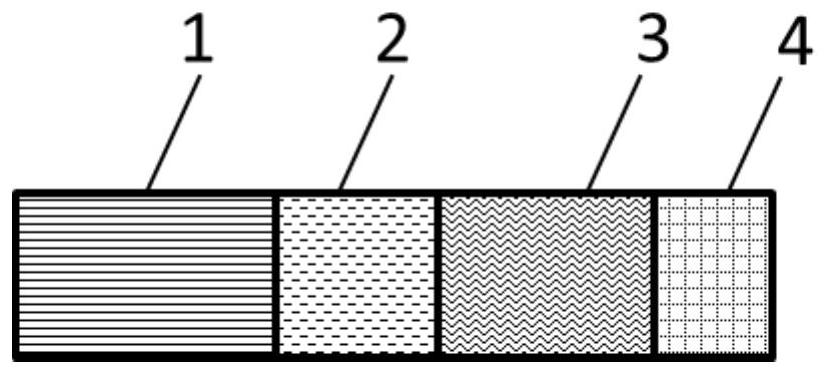

[0021] Such as figure 1 As shown, a sheet-type heating cigarette containing a limiting element includes a thin section 1 , a limiting element section 2 , a cooling section 3 and a filtering section 4 .

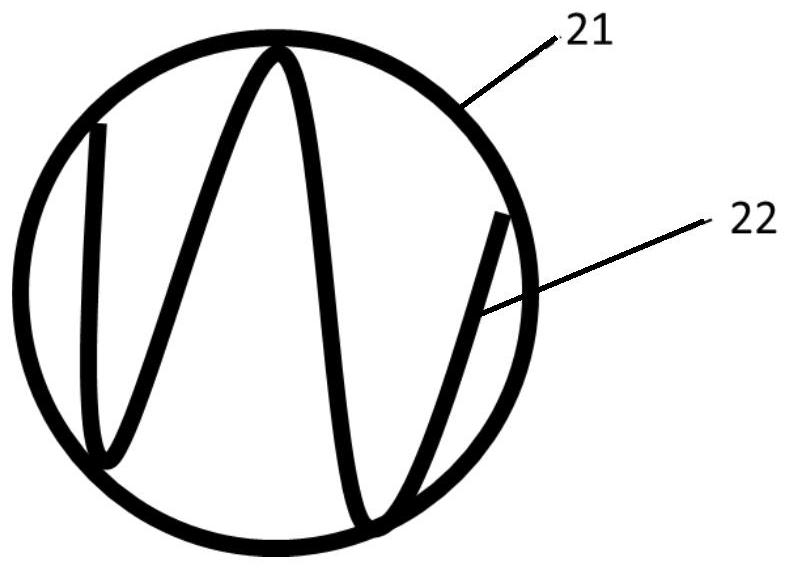

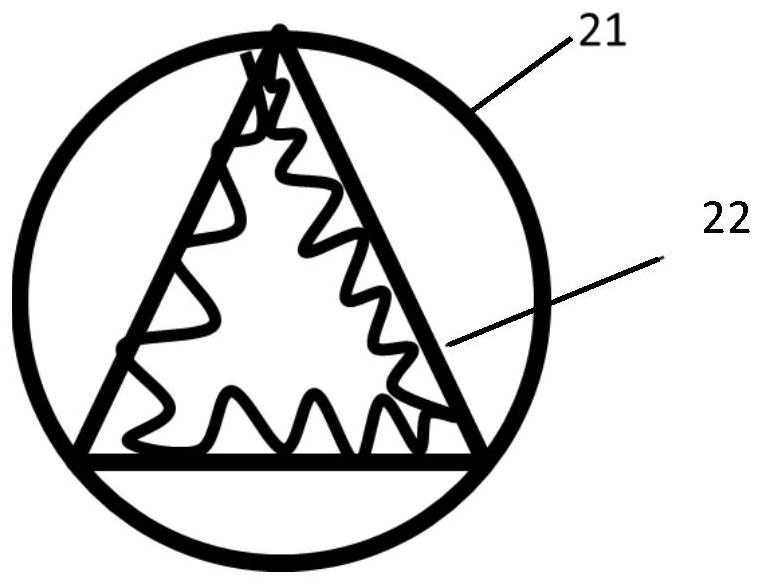

[0022] Such as Figure 2-4 As shown, the present invention designs a heating cigarette limiting element used in the limiting element section 2, which consists of a wrapping component 21 and a limiting component 22 placed inside the wrapping component 21.

[0023] During specific implementation, the cross-sectional area of the limiting part inside the wrapping part accounts for 20% to 70% of the cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com