Tunnel assembly for wind driven generator testing

A technology for wind turbines and tunnels, which is used in the monitoring of wind turbines, wind turbines, components of pumping devices for elastic fluids, etc. Long and other problems, to achieve the effect of simple structure, extended service life, simple and easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

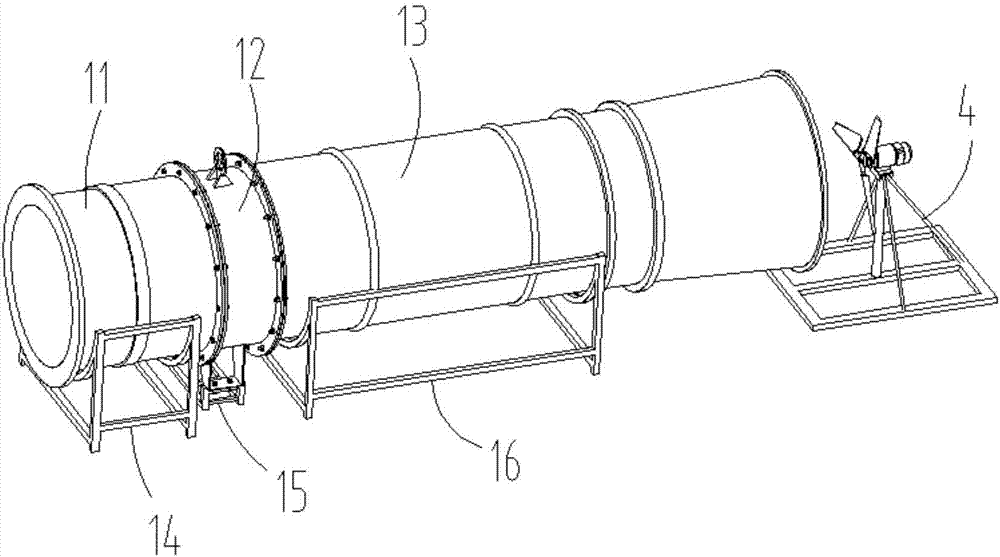

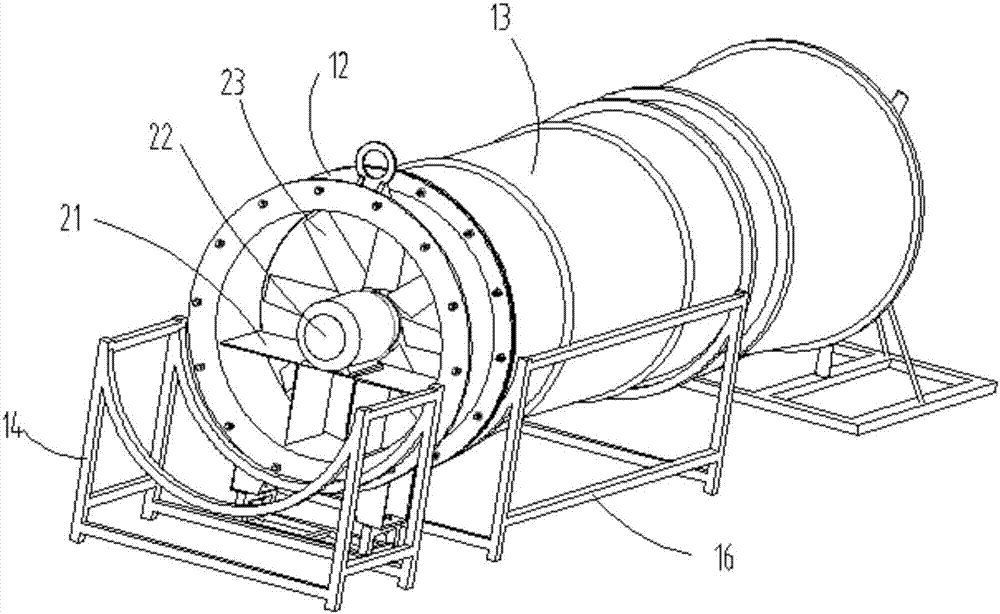

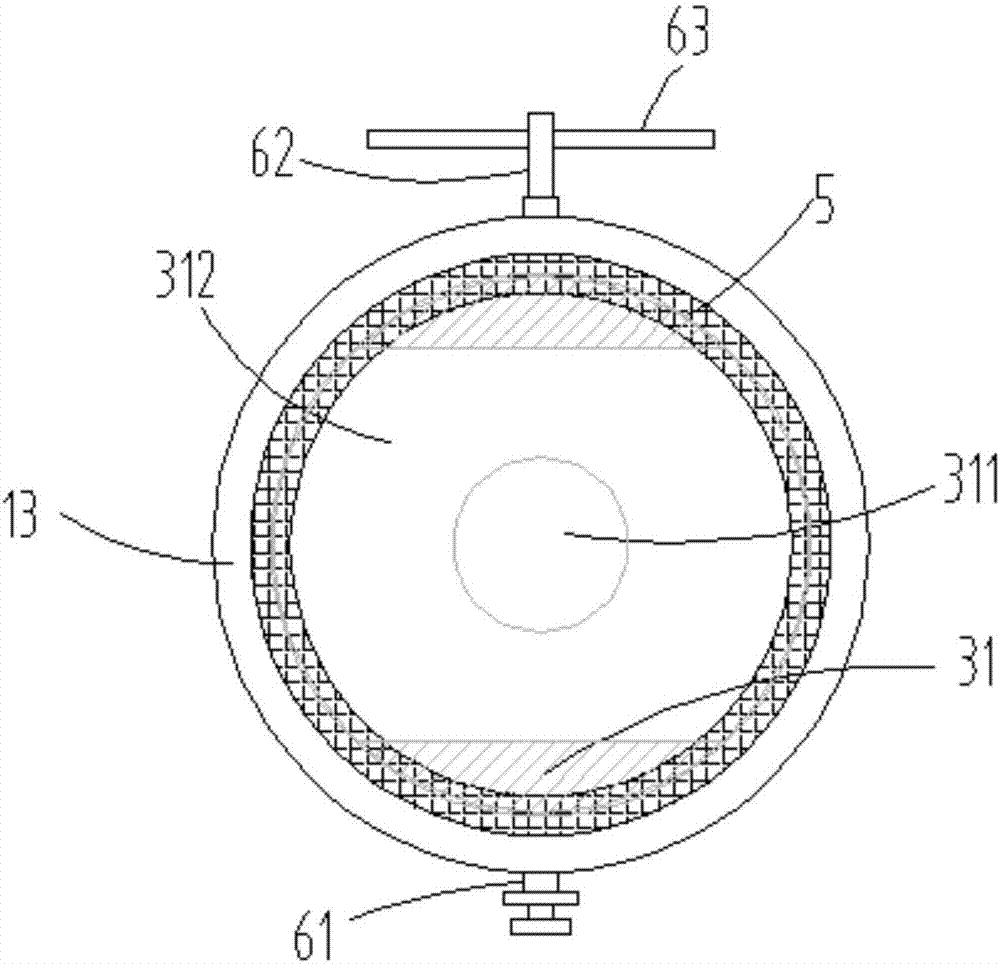

[0025] like Figure 1 to Figure 6 , the present invention discloses a tunnel assembly for wind power generator testing, including a first air duct 11, a second air duct 12, a third air duct 13, a first support frame 14, a fixed frame 15, and a third support frame 16 , blast mounting frame 21, motor 22, fan 23, wind speed regulating ball 31 and generator 4, the first air duct 11 and the third air duct 13 are fixedly connected with the two ends of the second air duct 12 respectively, the first air duct 11 and the third air duct 13 are respectively supported on the first supporting frame 14 and the third supporting frame 16, and the second air duct 12 is fixedly connected with the fixing frame 15. The blast mounting frame 21 is fixed in the inner cavity of the second air duct 12, the motor 22 is fixed on the blast mounting frame 21, and the output shaft of the motor 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com