Intercooler inspection device

A technology of checking tools and appliances, which is applied in the field of testing equipment, can solve problems such as the inability to quickly detect the position and bending angle of the air inlet and outlet pipes of the intercooler, the product cannot be measured quickly, etc., and achieve good promotion and use value, convenient use, and all-round Accurately Measured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

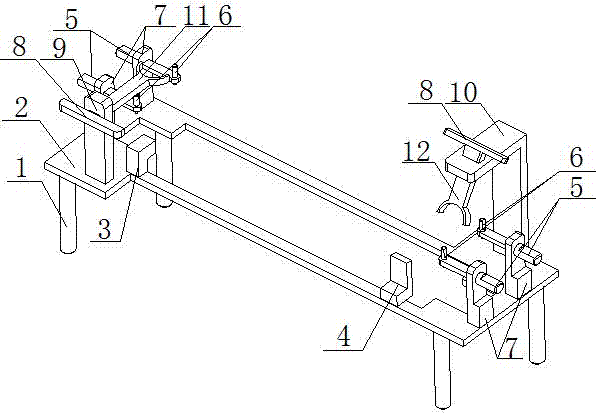

[0025] An intercooler inspection device of the present invention includes a column 1 and a inspection tool plate 2, the inspection tool plate 2 is a Z-shaped right-angle structure inspection tool plate 2, and the middle part of the inspection tool plate 2 is provided with an opening with a convex symmetrical structure Groove, column 1 is fixed at the four top corners of the inspection tool plate 2; also includes core body positioning module, installed machine positioning module, inlet and outlet air pipe positioning module; core body positioning module, installed machine positioning module, inlet and outlet air pipe positioning module respectively through the bolt Fixed on the inspection tool plate 2; one end of the middle part of the test tool plate 2 is provided with two right-angled positioning blocks on the same side. The positioning blocks include the main piece positioning block 3 and the guard plate positioning block 4, and the main piece positioning block 3 The thicknes...

Embodiment 2

[0027] An intercooler inspection device of the present invention includes a column 1 and a inspection tool plate 2, the inspection tool plate 2 is a Z-shaped right-angle structure inspection tool plate 2, and the middle part of the inspection tool plate 2 is provided with an opening with a convex symmetrical structure Groove, column 1 is fixed at the four top corners of the inspection tool plate 2; also includes core body positioning module, installed machine positioning module, inlet and outlet air pipe positioning module; core body positioning module, installed machine positioning module, inlet and outlet air pipe positioning module respectively through the bolt Fixed on the inspection tool plate 2; one end of the middle part of the test tool plate 2 is provided with four positioning blocks with a right-angle structure on the same side. The positioning blocks include the main piece positioning block 3 and the guard plate positioning block 4, and the main piece positioning bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com