A method and device for measuring surface topography of a workpiece

A surface topography and workpiece surface technology, applied in the field of measuring the surface topography of workpieces, can solve the problems of unrealistic measurement of surface topography and high cost, and achieve the effect of small measuring range, large measuring range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

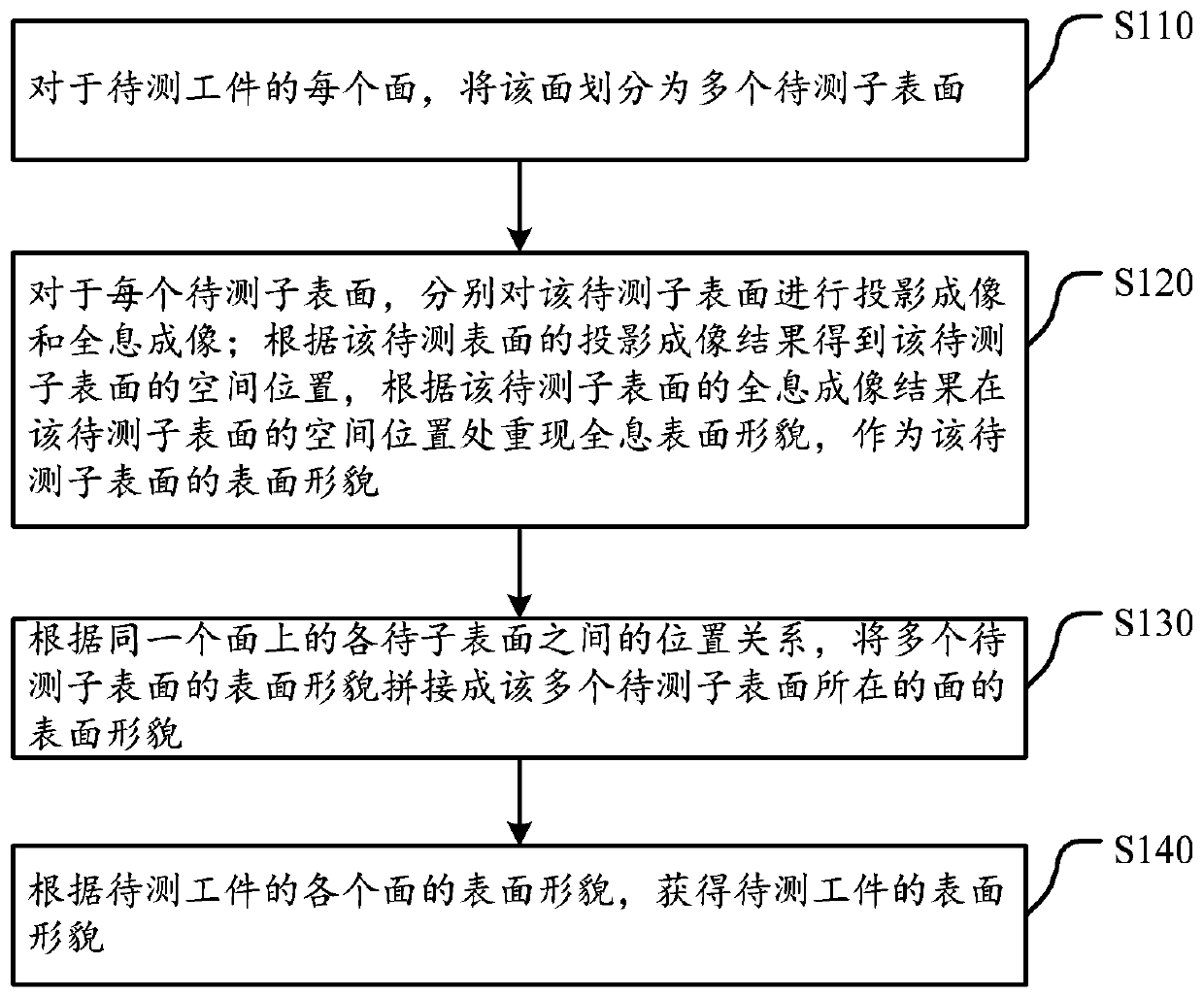

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

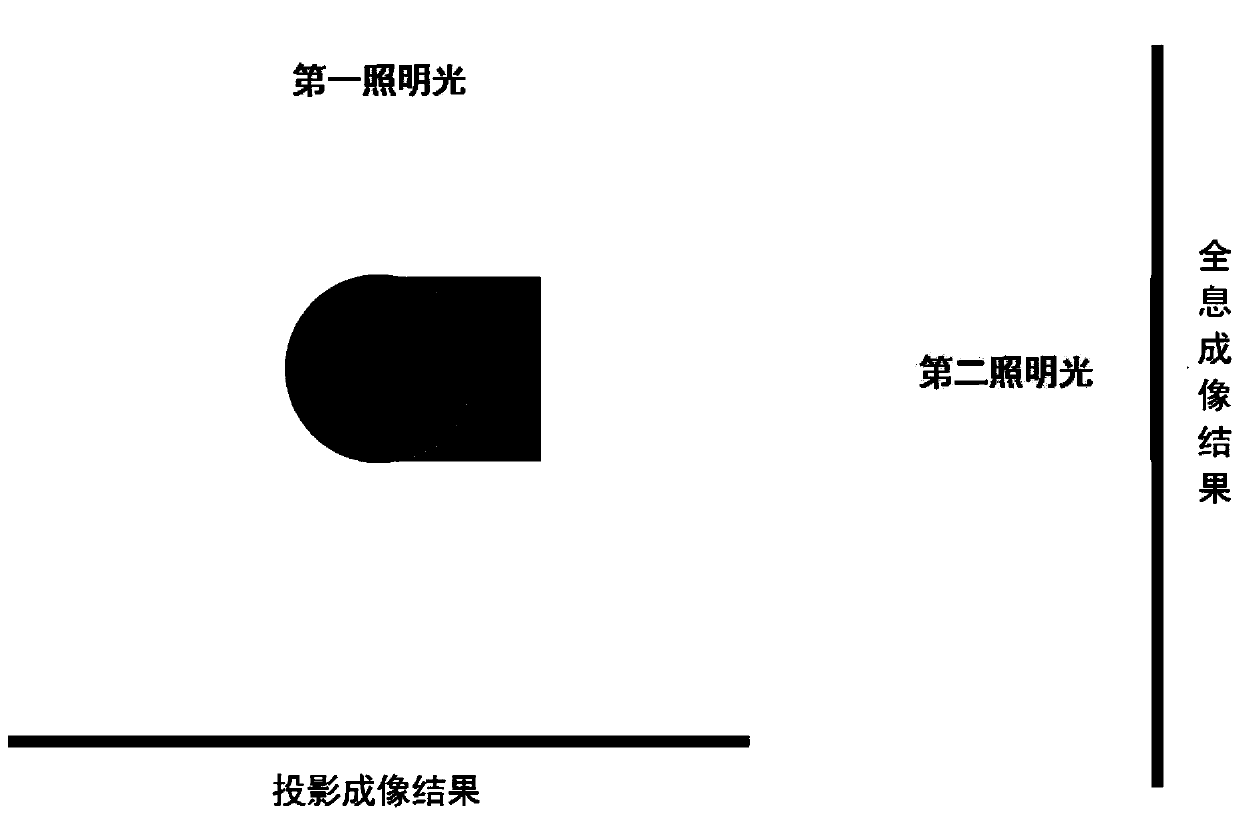

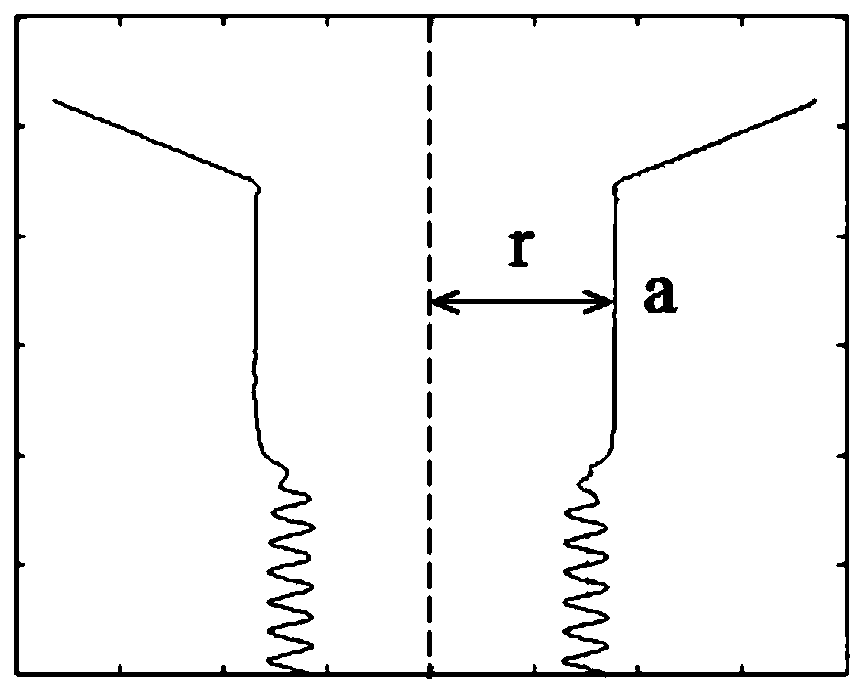

[0057] First, the terms appearing in the present invention are explained: projection imaging is also called projection method. Projection method is a measurement method designed to image the outer contour of an object based on the principle that light can only propagate along a straight line. Simple projection method (not Using any numerical processing process), the imaging accuracy is above 11 μm, and theoretically, the projection method cannot achieve imaging below 11 μm. Holographic imaging, also known as holographic method, is an imaging method that uses photocoupler devices (CCD, etc.) to record holograms. In addition to the imaging function, holographic method can also be used for measurement. The biggest advantage of using hologr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com