Apparatus for measuring thickness of sediment layer of rotary excavating bored pile

A layer thickness and bored pile technology is applied in the field of devices for measuring the thickness of the slag layer of rotary excavation bored piles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

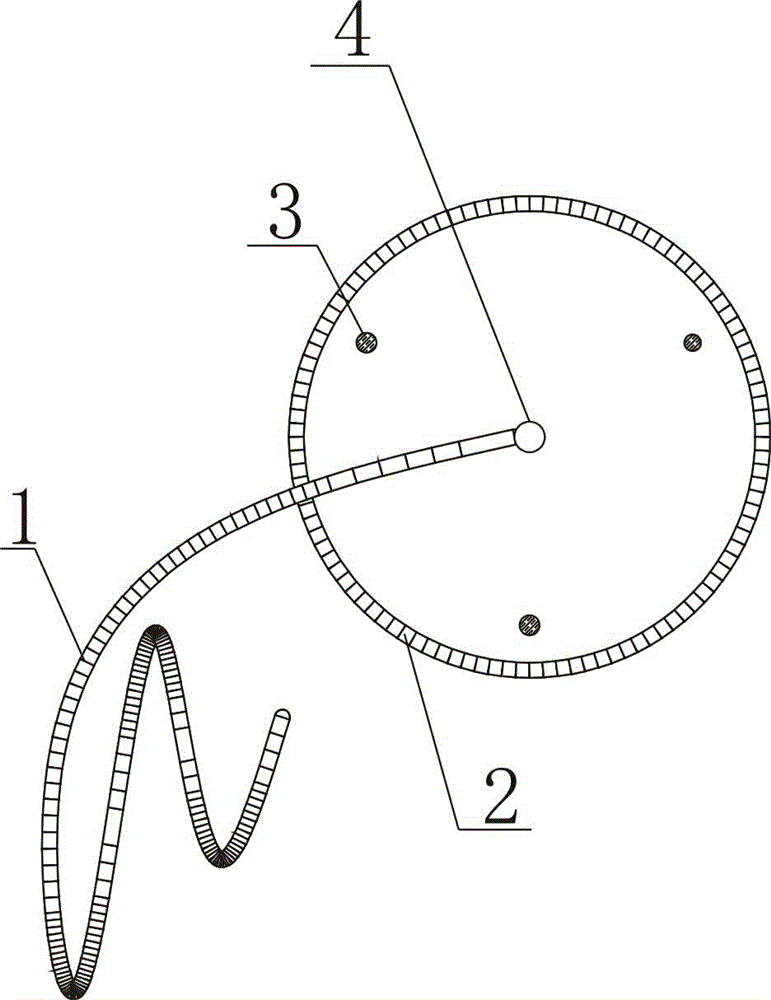

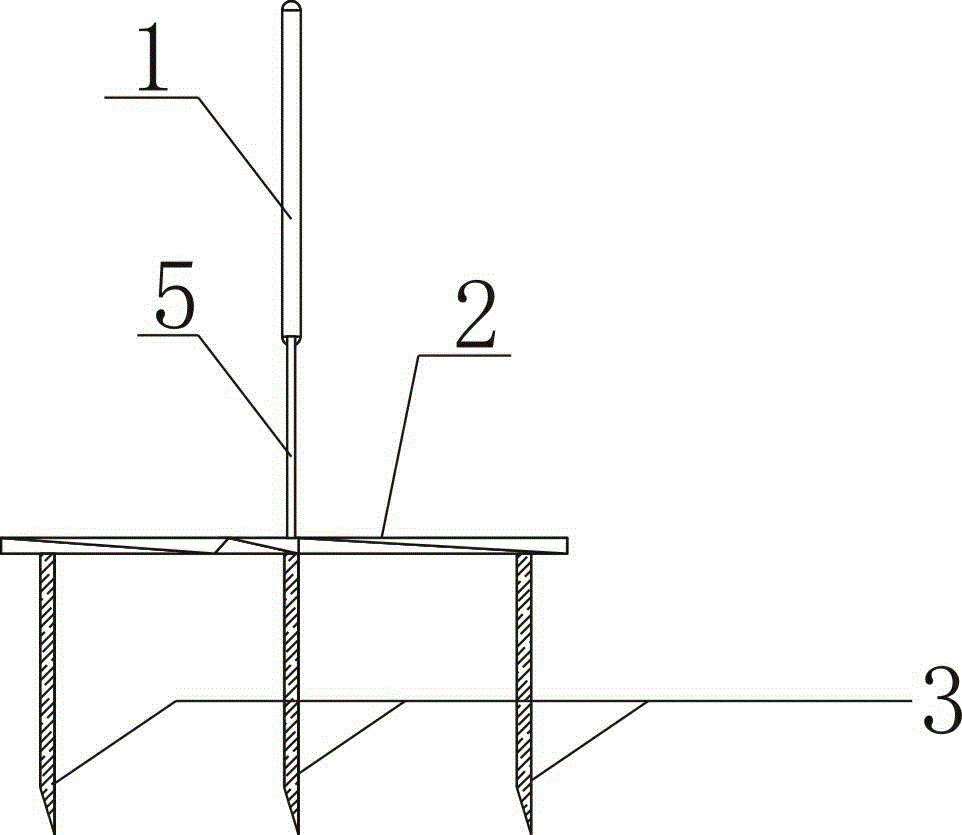

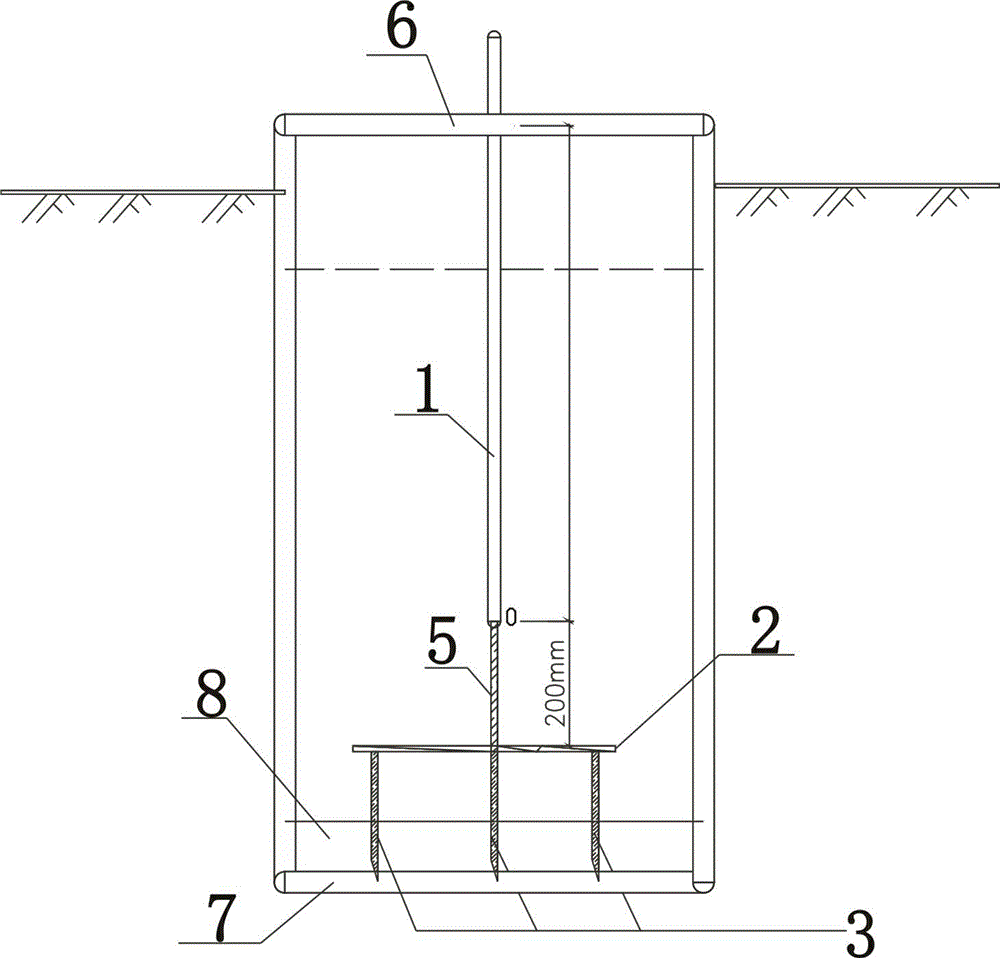

[0015] Such as figure 1 , figure 2 As shown, a device for measuring the thickness of the sediment layer of a rotary drilling bored pile includes a steel ruler 1 and a steel triangular support disc. The steel triangular support disc is composed of three long steel bars 3 fixedly welded on the edge of the steel disc 2, and the center of the steel disc 2 is provided with a round hole 4 with a wire mouth, and the reinforcing bar screw 5 passes through the round hole 4 and Steel disc 2 connection.

[0016] The steel disc 2 is a thin steel disc with a thickness of 3 mm. The long steel bar 3 is a 200mm long steel bar of φ8. The diameter of the circular hole 4 with the wire mouth is 10mm. Described reinforcement screw rod 5 is the 200mm long steel bar of φ 10. Described steel ruler 1 adopts 50m steel ruler.

[0017] Steps:

[0018] Step 1: During the process of embedding the steel casing 6, use a level to measure so that the elevation of the upper edge of the steel casing 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com