Composite micro-pore-diameter filter membrane, preparation method thereof and application of composite micro-pore-diameter filter membrane in field of water treatment

A technology of microporous membrane and pore size, which is applied in water/sewage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of undiscovered patent reports and achieve the accuracy of measurement Improve, ensure normal operation, and improve the effect of membrane filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0024] According to a typical embodiment of the present invention, the preparation method of the composite microporous filter membrane comprises: the membrane material is mixed cellulose resin (made by mixing nitrocellulose and cellulose acetate); The filter membrane is prepared according to the following process:

[0025] A filter membrane with a pore size of 0.45 μm + a filter membrane with a pore size of 5 μm or 3 μm is prepared by a lamination method to prepare a dense and homogeneous 0.45 μm membrane, which is pressed on a filter membrane with a pore size of 5 μm or 3 μm or dip-coated with a polymer solution by dip coating On microporous membranes with different pore sizes, and then dried to form → finished product.

[0026] During the production process of the composite microporous membrane, filter membranes of different colors are superimposed. During the detection and analysis process, it is convenient to distinguish the pore size of the upper and lower surfaces of the...

example 1

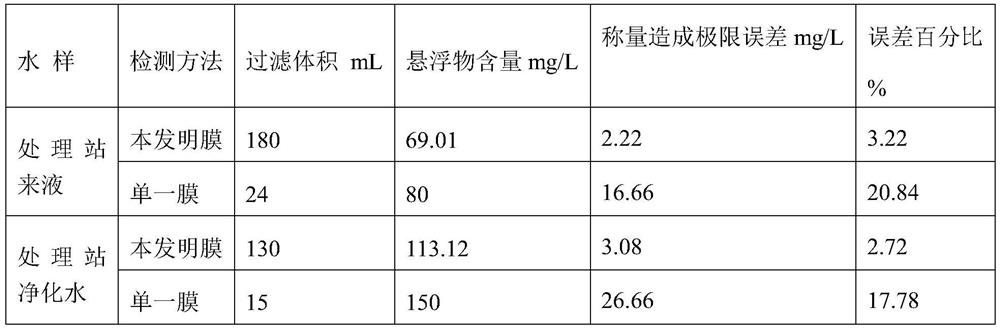

[0032] Table 1 The effect of the pore size of the double filter membrane on the filtration time (oilfield unpurified tertiary production sewage)

[0033] Pore diameter of the upper filter membrane, μm Lower filter membrane pore size, μm 100ml, membrane time Suspended matter content, mg / L / 0.45 >30′ 154 1.2 0.45 4′45″ 56 2 0.45 3′14″ 52 3 0.45 1′49″ 50 5 0.45 1′46″ 50

[0034] Table 2 The effect of the pore size of the double filter membrane on the filtration time (oil field purification of tertiary production sewage)

[0035] Pore diameter of the upper filter membrane, μm Lower filter membrane pore size, μm 100ml, membrane time Suspended matter contentmg / L - 0.45 1h filter 50ml 41 1.2 0.45 46′ 29 2 0.45 25′ 25 3 0.45 12′ 22 5 0.45 6′ 21

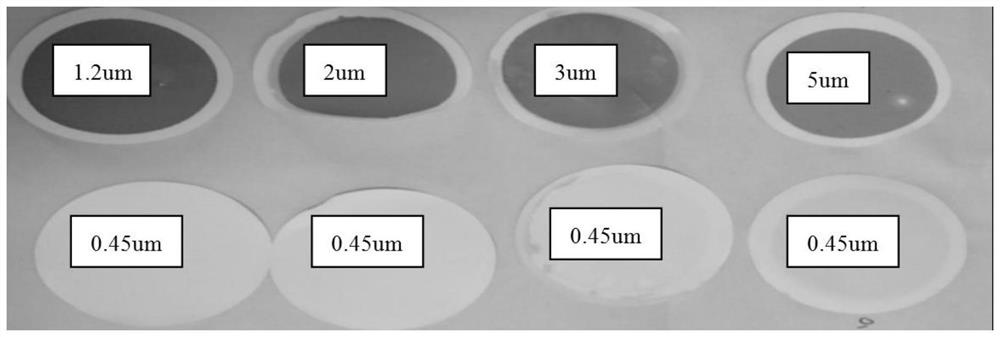

[0036] figure 1 Double-layer microporous membrane filtration, comparison of surface conditions after separation of upper and ...

example 2

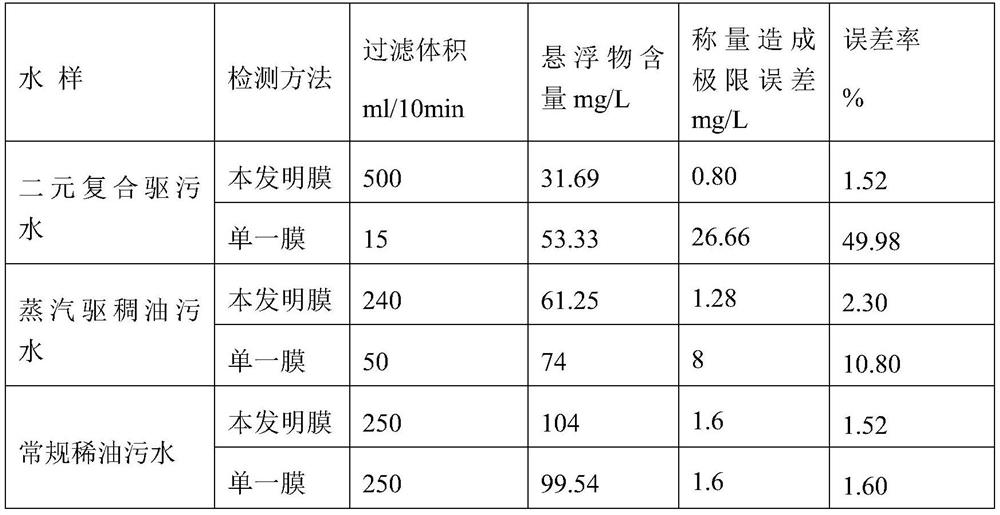

[0039] Table 3 Effects of microporous membranes with different pore sizes on filtration capacity (oilfield unpurified tertiary mining wastewater)

[0040] Aperture / μm 10min membrane volume Measured suspended matter content, mg / L 0.45 60 255 1.2 139 224 2 158 206 3 192 185 5 253 167

[0041] It can be seen from the above table 2 that with the enlargement of the pore size, the filtration capacity is also increasing, and the measured value of the suspended matter content is also decreasing. Compared with the single filter membrane of 0.45μm, the filter membrane formed by stacking 5μm and 0.45μm filter membranes can increase the filtration volume from 60mL to 155mL, and the difference in suspended matter content is 2.35%.

[0042] According to the above-mentioned indoor evaluation results, the inventor believes that the above-mentioned results further reflect that the filter membrane pore size is too small, and more suspended matter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com