Automatic assembling machine for adjusting studs

A technology for adjusting studs and assembling machines. It is used in manipulators, program-controlled manipulators, and metal processing. It can solve the problems of polluted product surface quality, bumped operator's fingers, and improper assembly. High-level, easy-to-replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

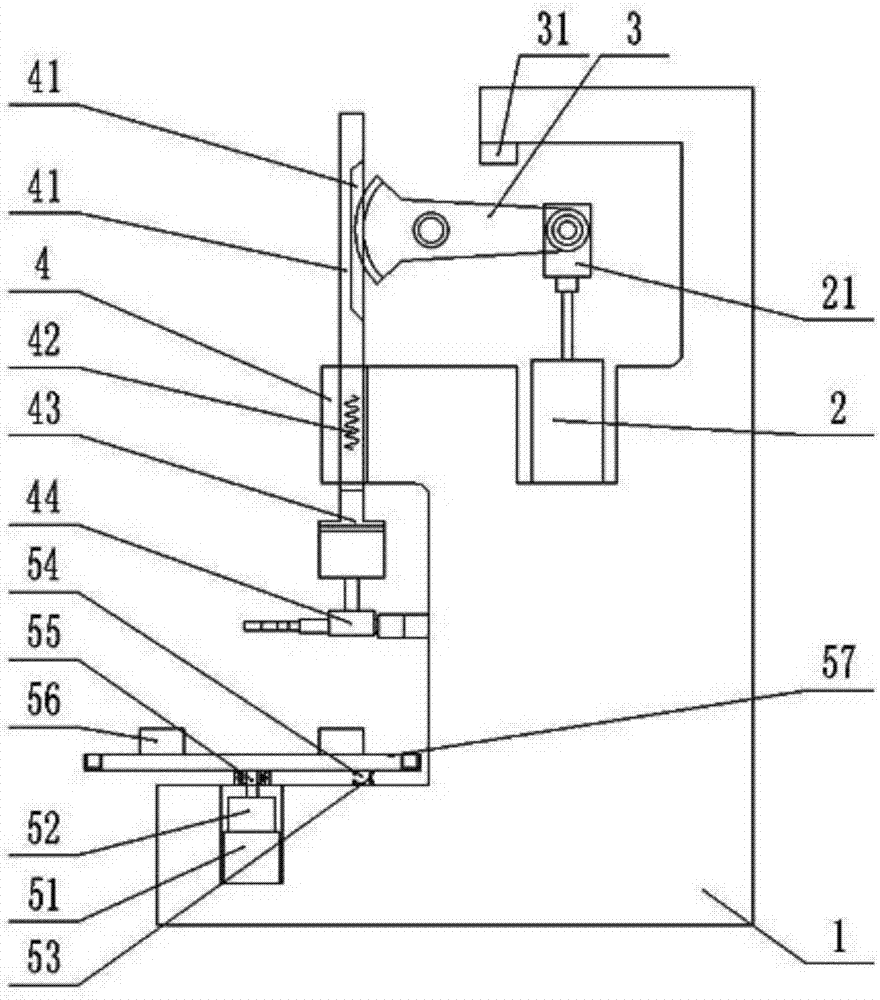

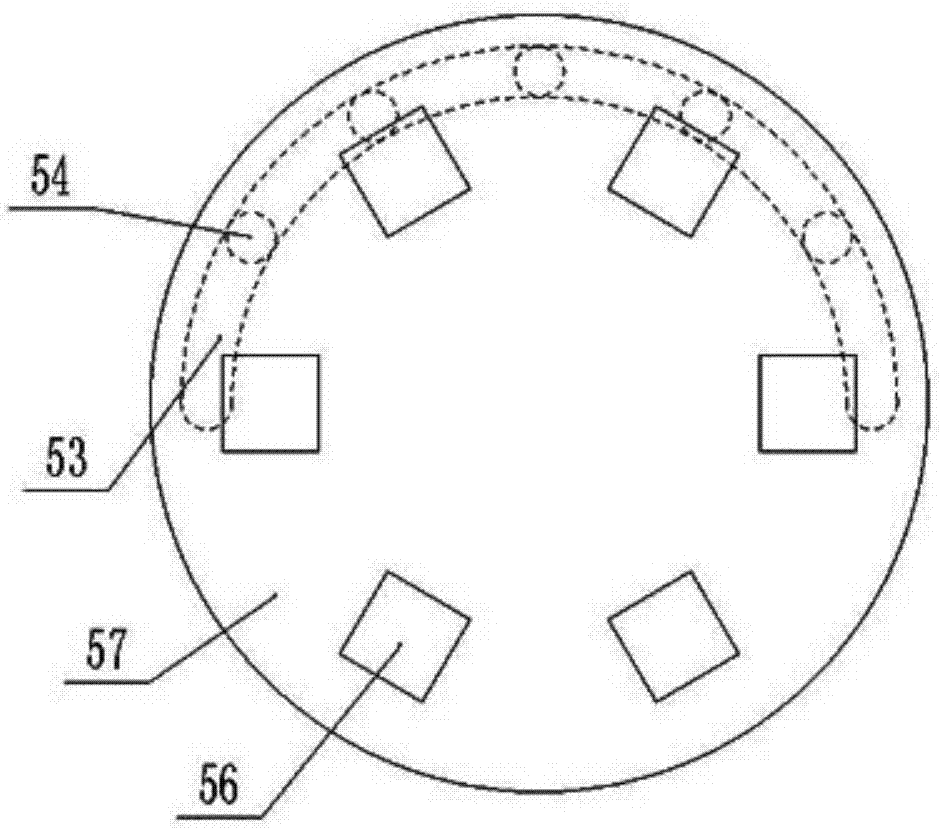

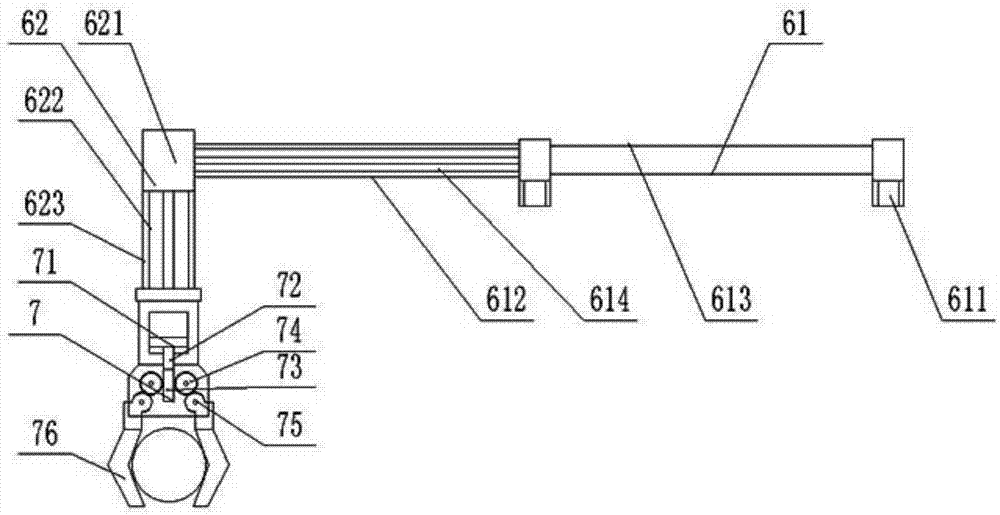

[0020] Such as Figure 1-3 As shown, an automatic assembly machine for adjusting studs includes a frame 1, a transition rod 41, a drive assembly 5 and a feeding device 6, the rear of the frame 1 is provided with a cylinder 2, and the rear of the frame 1 is provided with a cylinder for installation Seat, cylinder 2 is fixedly installed in the cylinder mounting seat,

[0021] The output shaft of the cylinder 2 is driven to connect the drive push rod 21, and the drive push rod 21 is rotatably connected to the sector gear 3, and the sector gear 3 is arranged on the frame 1 through shaft rotation; the transition rod 41 is provided with a rack 411, and the sector gear 3 Mesh and cooperate with the rack 411; in the working state of the present invention, the cylinder 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com