Main tapping channel of blast furnace

A tapping channel and blast furnace technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as unusable tapholes, unavailable maintenance, and unsatisfactory maintenance results, so as to reduce the probability of cracking and facilitate Removal and installation, the effect of accelerating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

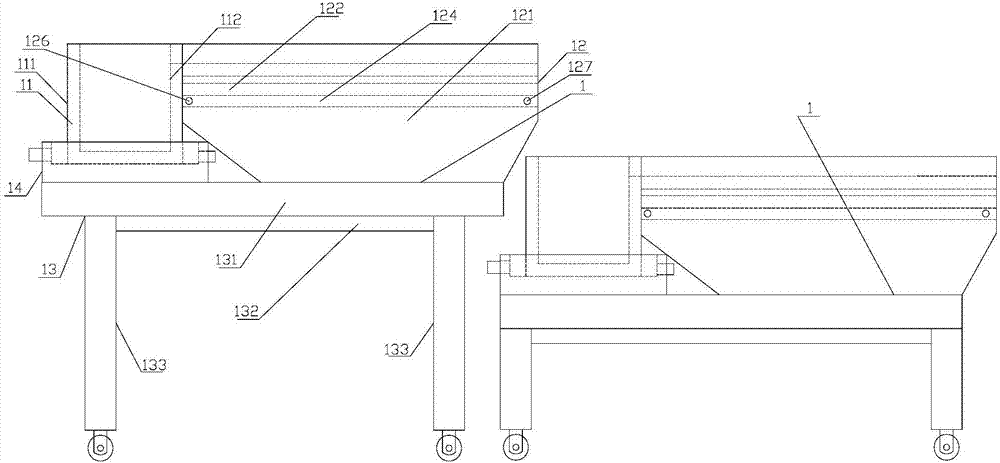

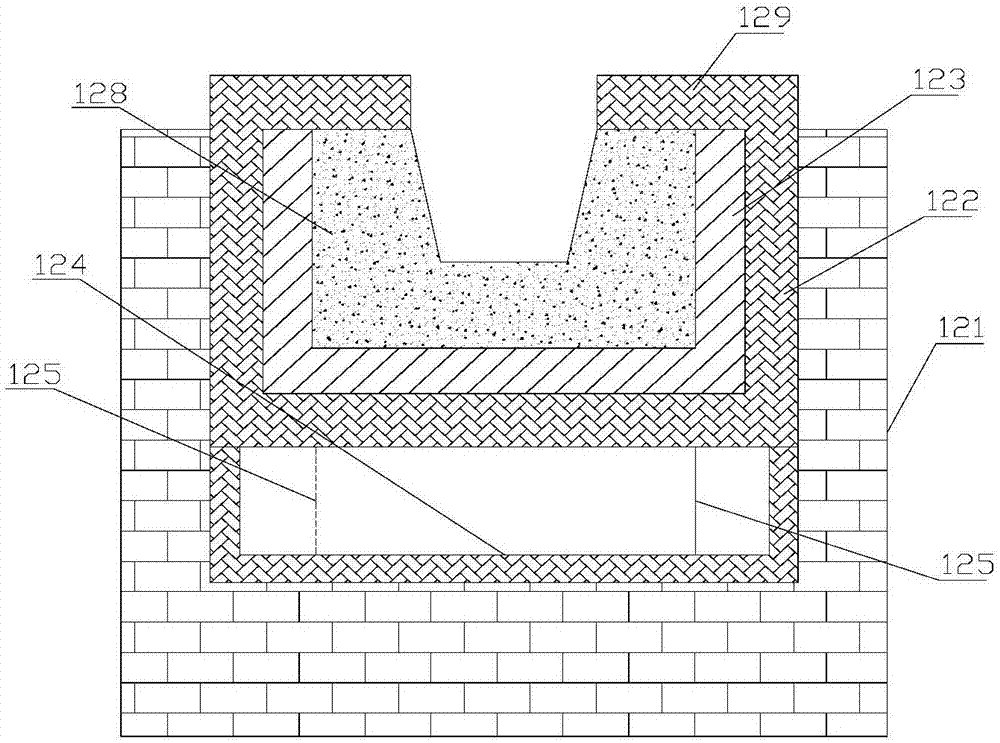

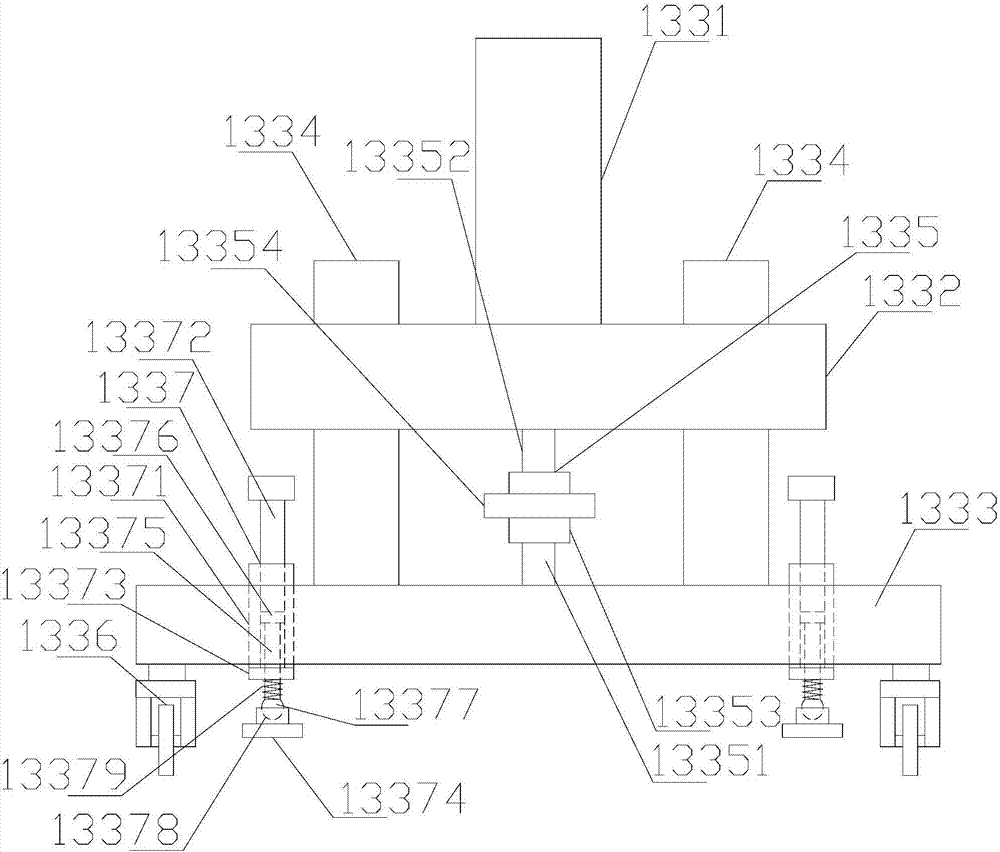

[0019] refer to figure 1 , figure 2 and image 3 , a main tapping channel of a blast furnace in the present invention includes several tapping channels 1, the tapping channels 1 include a transition channel 11, a channel body 12 and a frame body 13, and the frame body 13 is provided with a transition channel 11 and a channel body 12, the front end of the ditch body 12 communicates with the transition groove 11, the tapping groove 1 gradually decreases from front to back in a stepped manner, and the highest tapping groove among the two adjacent tapping grooves 1 The output end of 1 is located above the transition trough 11 of the lowest tap chute 1. The frame body 13 includes an installation platform 131, a girder 132 and a support mechanism 133. The bottom of the installation platform 131 is provided with a girder 132. The two ends of crossbeam 132 are all provided with support mechanism 133, and described support mechanism 133 comprises support body 1331, upper base 1332, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com