Electric heating singeing machine

A technology of singeing machine and electric heating, which is applied in singeing, textile and papermaking, and fabric surface trimming, etc. It can solve the problems of difficult control of singeing quality, uncontrollable singeing temperature, and uncontrollable singeing temperature. Guarantee singeing quality, improve singeing efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

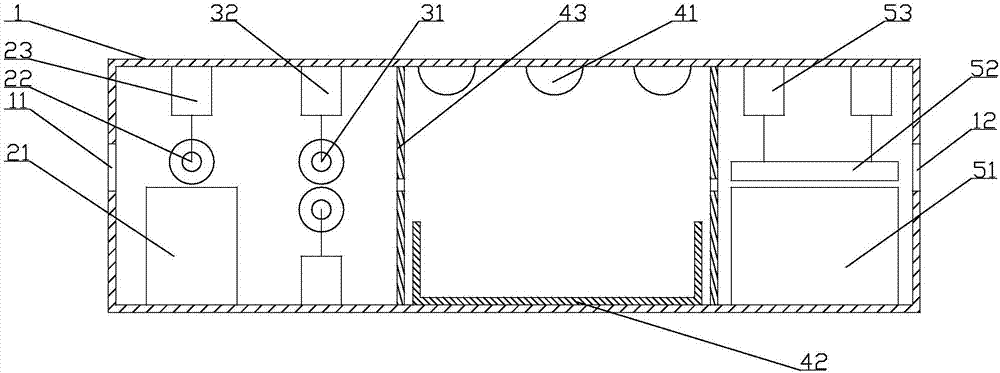

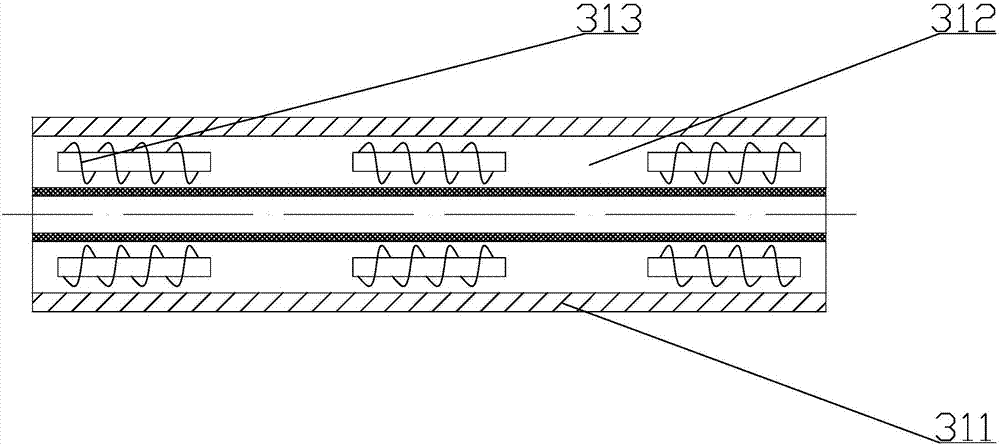

[0025] The present invention as Figure 1-2 Shown, a kind of singeing machine comprises inlet 11, outlet 12, initial flattening device, singeing device, water mist cooling device, hot pressing device and controller; Said initial flattening device, singeing device, water mist The cooling device and the hot pressing device are sequentially arranged inside the shell 1, and the inlet 11 and the outlet 12 are respectively arranged at two ends of the shell; There is a gap between the hot pressing rollers 31, each of the hot pressing rollers 31 is connected to a hydraulic device 32, and the hydraulic device 32 is connected to the controller; when the paired hot pressing rollers are singeing, Heat the hot press roller to a suitable high temperature, and then use the high temperature to perform singeing. Since the hot press rollers are set in pairs, the fabric that needs to be singed can be singed on both sides after one singeing, and there is no need for singeing during the singeing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com