A printing and dyeing production line

A production line and equipment technology, applied in the field of printing and dyeing, can solve the problems of inability to blow fluff, low singeing effect, inconvenient use, etc., and achieve the effects of convenient use, reduced structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

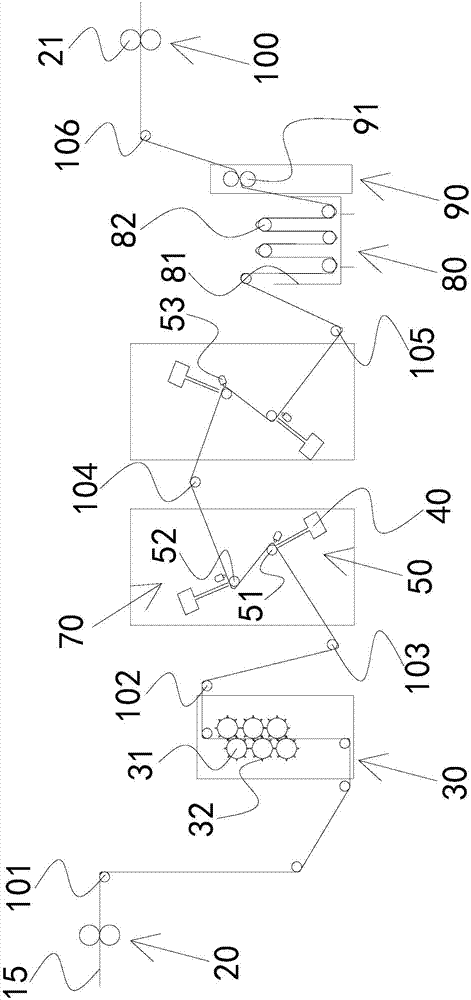

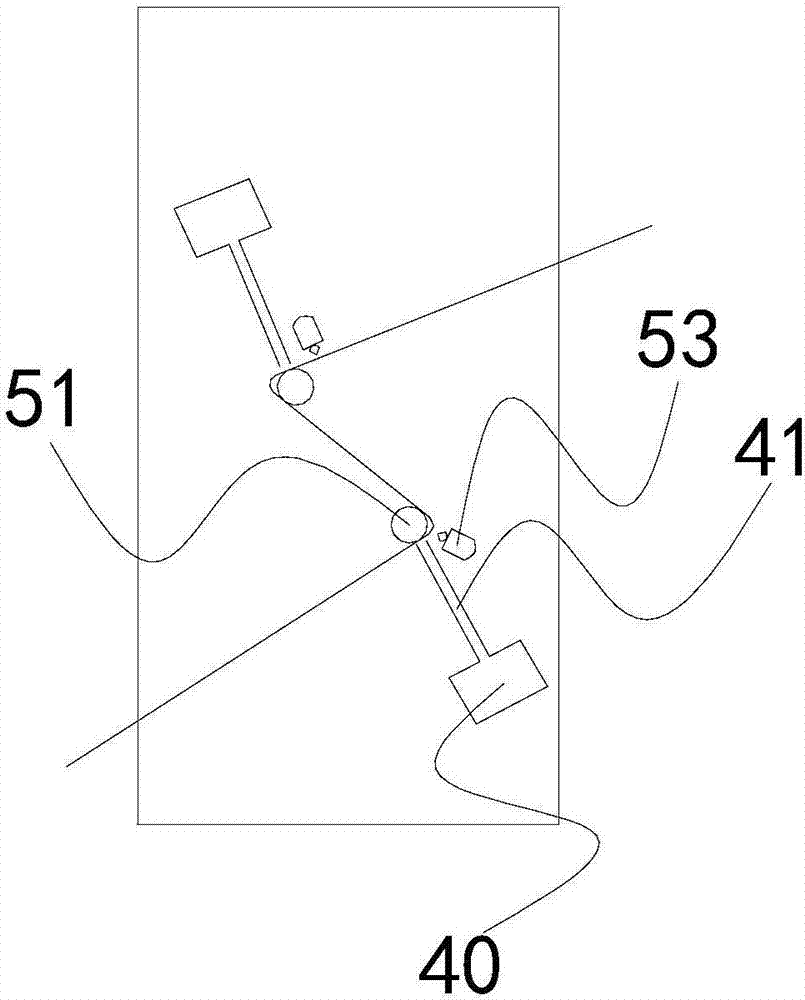

[0091] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0092] see figure 1 In this embodiment, cotton printing and dyeing is taken as an example. In this embodiment, a printing and dyeing production line, the printing and dyeing production line includes pre-processing equipment, singeing equipment, mercerizing machine, dyeing and printing equipment and finishing equipment in sequence along the cloth treatment process; The processing equipment is used for desizing, refining and bleaching; the mercerizing machine uses concentrated alkali solution to treat the cloth, and its surface presents a silky luster, and more importantly, its dimensional stability is improved, that is, the cloth is set; the dyeing and printing equipment is used for Print the fabric; the finishing equipment sorts and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com