Water-solid mixed slurry loading and pre-pressing dehydration consolidation method

A technology of mixing slurry, loading and preloading, applied in drainage, earth square drilling, mining equipment, etc., can solve the problems of non-dehydration of water-solid mixed slurry, long consolidation period, high consolidation cost, etc., to improve the compactness and strength, reduce consolidation cost, and shorten the effect of consolidation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

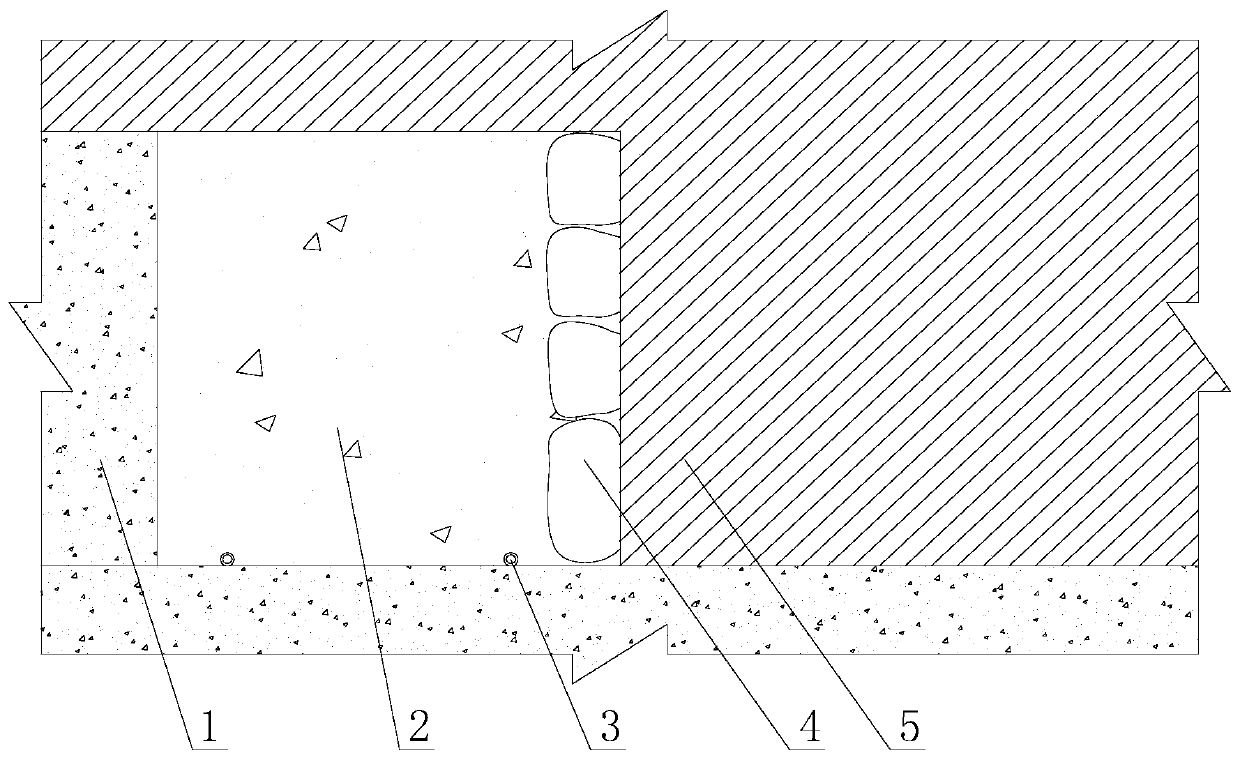

[0049] Such as figure 1 , image 3 and Figure 5 As shown, it is a preloaded dehydration consolidation scheme for the filling slurry. It is suitable for filling slurry consolidation in roadway type gobs such as road filling method, layered filling mining method and wall filling mining method.

[0050] (1) Build drainage facilities. Geotechnical blind ditches (drainage pipes 3 ) are arranged along the length direction of the area to be filled 2 , and the geotechnical blind ditches (drainage pipes 3 ) are covered with geotextiles to prevent the loss of fine particles. The outer diameter of the geotechnical blind ditch (drainage pipe 3) is 30mm-80mm. Preferably, the outer diameter of the geotechnical blind ditch (drainage pipe 3) is 50mm. The spacing of geotechnical blind ditch is 1m~5m. Preferably, the distance between the geotechnical blind ditch is 2m.

[0051] (2) Install the capsule preloading system (preloading component 4). In order to prevent the airbag body from ...

Embodiment 2

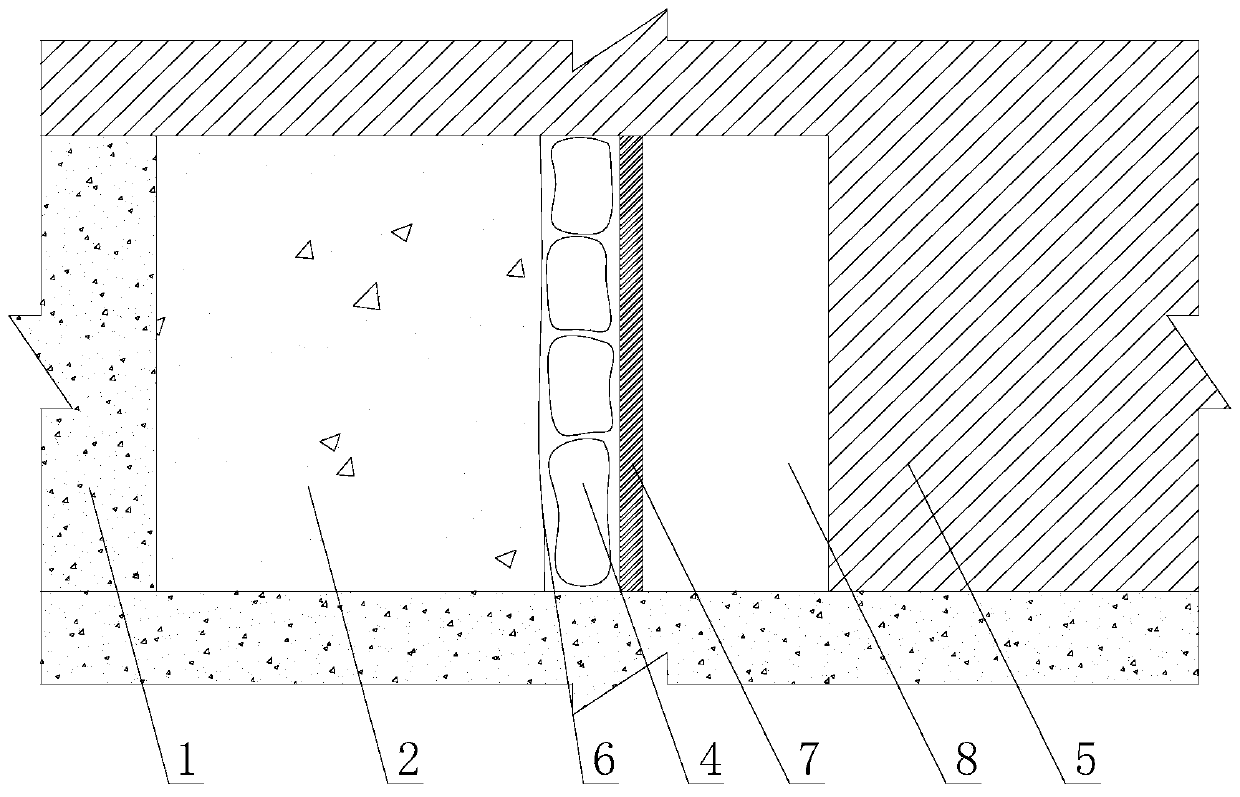

[0058] figure 2 and Figure 4 Preload dehydration and consolidation scheme for dewatering filling slurry on retaining surface of reserved space 8. It is suitable for the consolidation of filling slurry in roadway type gobs such as road filling method, layered filling mining method and wall filling mining method.

[0059] Carry out the isolation of the permeable enclosure 7 of the area to be filled 2, build drainage facilities, construct the permeable enclosure 7 in the empty area, divide the empty area into the area to be filled 2 and the reserved space 8, and make the area to be filled 2 form a permeable seal body. Construction process of permeable enclosure 7: Install hydraulic props along the full length of 2 weeks of the area to be filled, and the spacing between props is 0.5m / root to 3m / root. Preferably, the distance between pillars is 1.5m / root. Hang the metal mesh at the full height and full length of the pillar near the area to be filled 2, the size of the metal m...

Embodiment 3

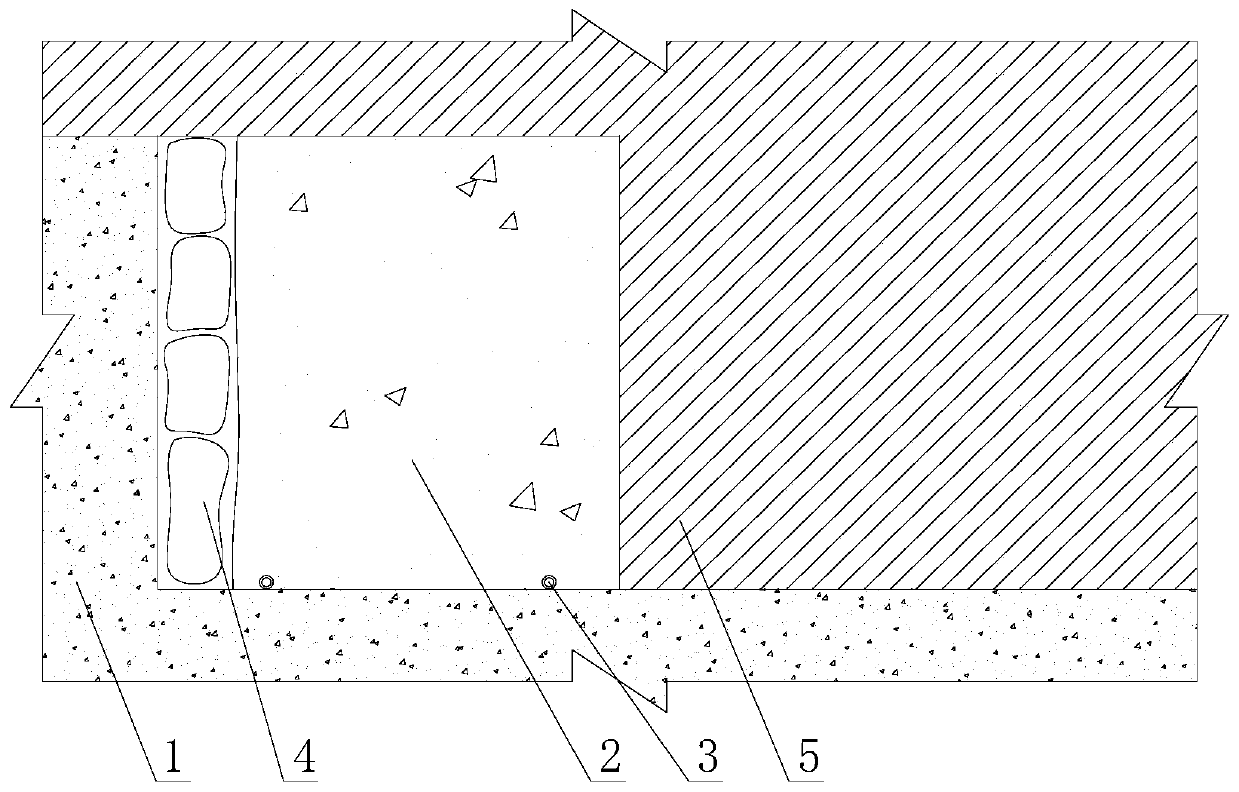

[0062] Such as figure 1 , image 3 and Figure 5 As shown, it is a preloaded dehydration consolidation scheme for the filling slurry. It is mainly suitable for filling slurry consolidation in roadway type gobs such as access filling method, layered filling mining method and wall filling mining method.

[0063] Firstly, the drain pipe 3 is built on the bottom of the area to be filled 2, and then the air bag preloading device is arranged on the side of the area to be filled 2, and then a custom-made filling mold bag 6 that is slightly larger in volume than the empty area to be filled is laid in the area to be filled 2 . The filling slurry is filled in the filling mold bag 6 , and when the filling slurry is full of the area 2 to be filled, the filling mold bag 6 and the area 2 to be filled are closely attached to each other. The filling mold bag 6 is processed by geotextile, requiring water-permeable and impermeable aggregate. The remaining steps are similar to Embodiment 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com