A kind of pellet loaded with nano-selenium and preparation method thereof

A technology of nano selenium and pellets, applied in the field of food nutritional additives, can solve the problems of unstable preparation process, high production equipment requirements, difficult content control, etc., and achieves the effects of suitability for industrial production, low cost and controllable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

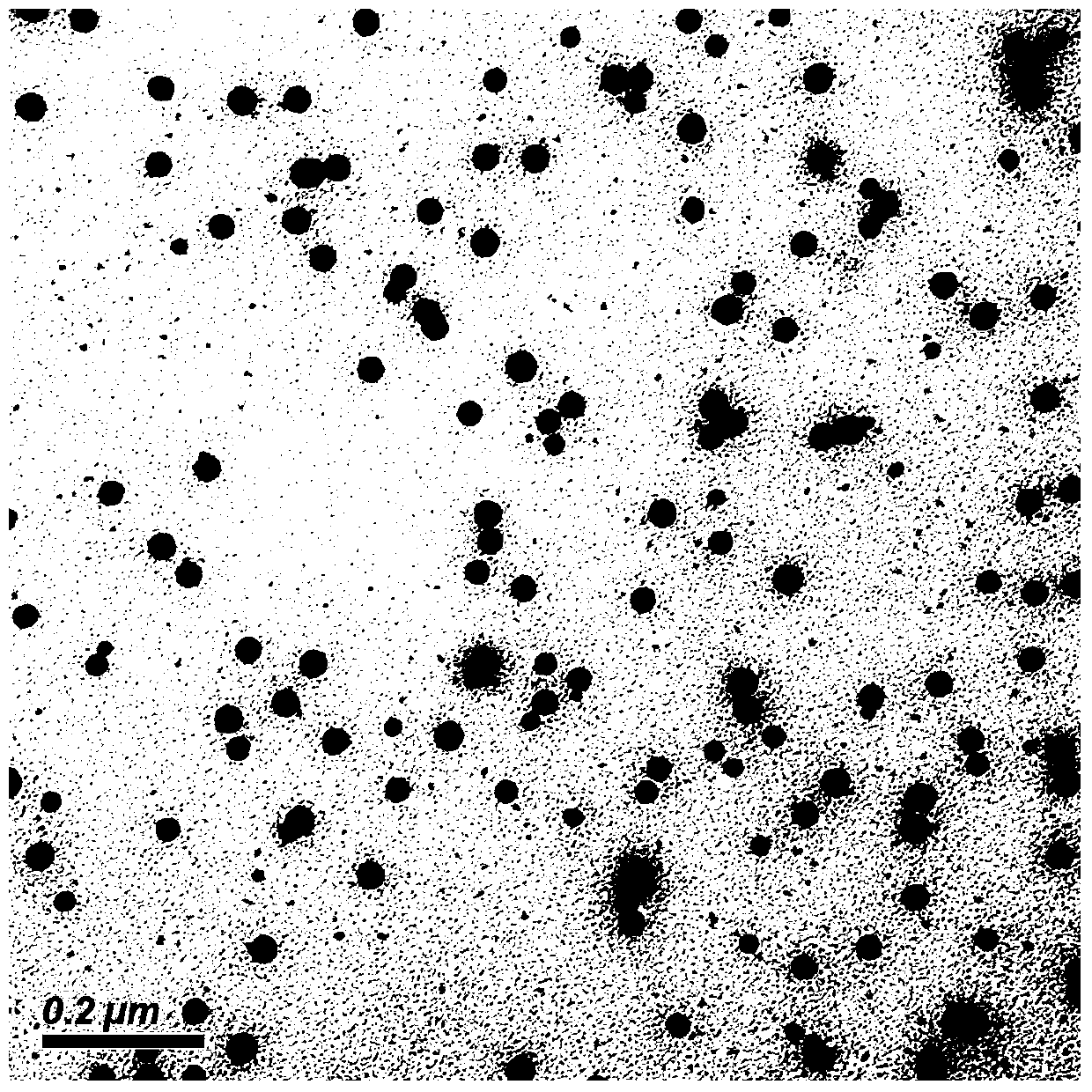

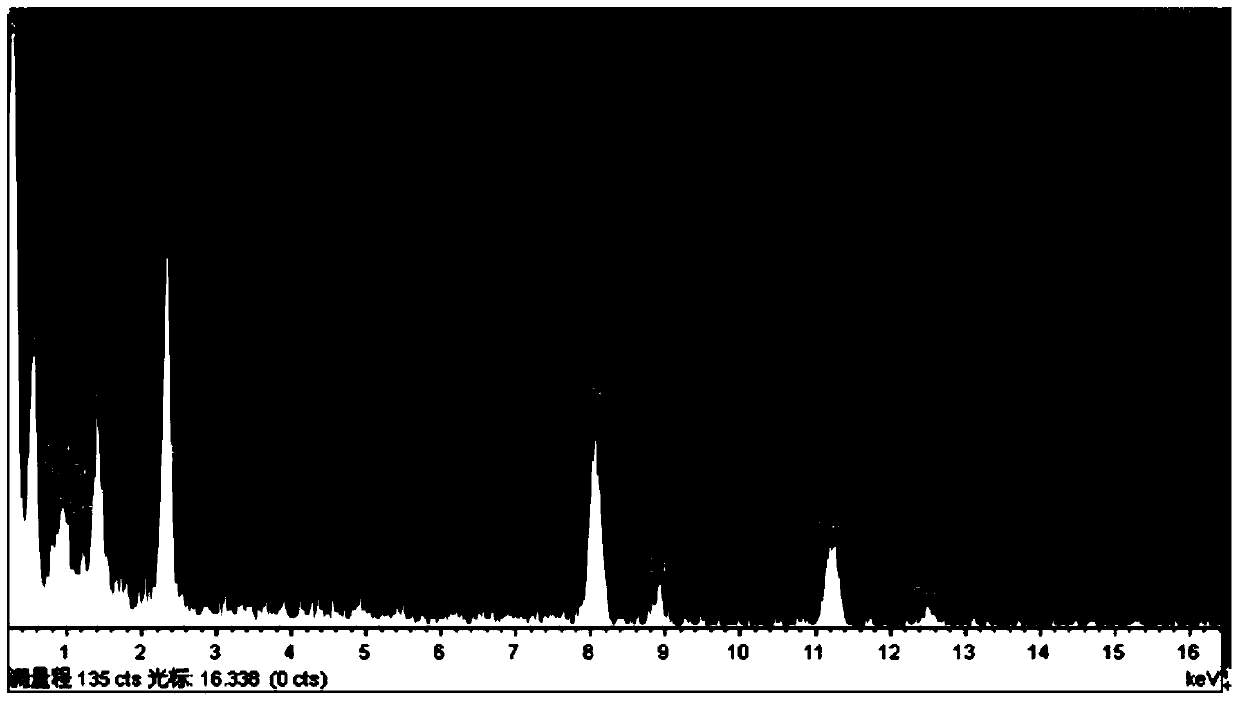

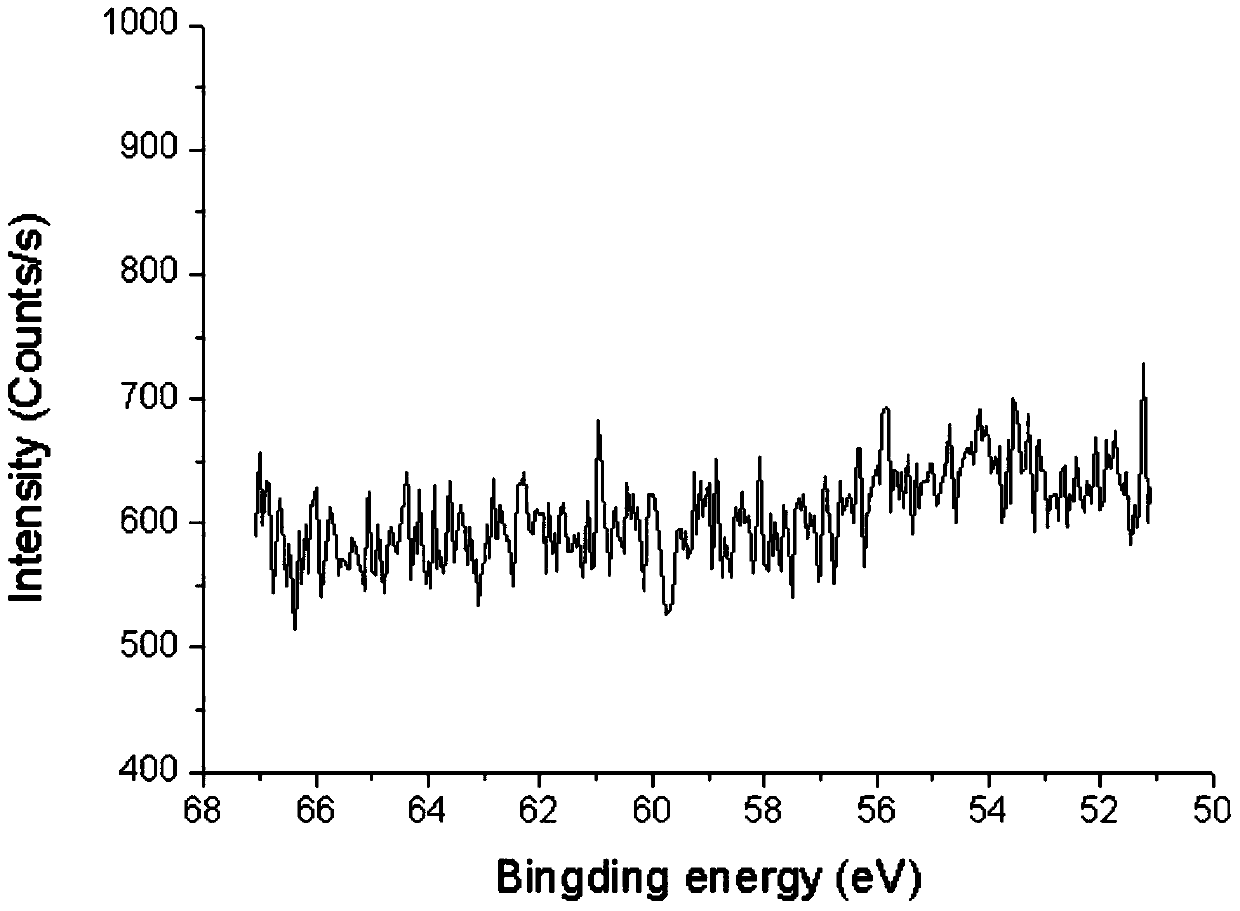

[0036] Dissolve 0.5g of chitosan in 100mL of 1% acetic acid solution, add 1.5g of ascorbic acid, after fully dissolving, add 0.15mg of sodium selenite, and stir until the orange in the solution no longer deepens. Then add 0.625g of chitosan and stir until completely dissolved to obtain nano-selenose sugar sol. The fluidized bed is used for sugar layer spraying and fluidized drying. The specific process parameters are: starch pellet core 350g, fed by bottom spraying method; air intake volume 170m 3 h -1 , the speed of the liquid supply pump is 2rpm, the inlet air temperature is 36-45°C, the material temperature is 28-35°C, and the atomization pressure is 0.16MPa; That is, 400 g of micropills loaded with nano-selenium were obtained. The pellets are regular and spherical, with a particle size of about 1 mm, uniform particle size distribution, and a light red surface. X-ray photoelectron spectroscopy (XPS) results showed that there was no Se 3d peak on the outermost layer of th...

Embodiment 2

[0040] Dissolve 0.25g of chitosan in 100mL of 1% acetic acid solution, add 0.5g of ascorbic acid, after fully dissolving, add 0.05mg of sodium selenite, and stir until the orange in the solution no longer deepens. Then add 10 g of sucrose and stir until completely dissolved to obtain nano-selenose sugar sol. The fluidized bed is used for sugar layer spraying and fluidized drying. The specific process parameters are: starch pellet core 350g, fed by bottom spraying method; air intake volume 160m 3 h -1 , the speed of the liquid supply pump is 2rpm, the air inlet temperature is 35-43°C, the material temperature is 26-34°C, and the atomization pressure is 0.19MPa; That is, 405 g of pellets loaded with nano-selenium were obtained. The pellets are regular and spherical, with a particle size of about 1 mm, uniform particle size distribution, and a reddish surface.

Embodiment 3

[0042] Dissolve 0.5g of sodium alginate in 100mL of ultrapure water, add 5g of ascorbic acid, after fully dissolving, add 0.5g of sodium selenite, stir until the orange color in the solution does not deepen, then add 50mL of water to obtain nano-selenoglycosol . The fluidized bed is used for sugar layer spraying and fluidized drying. The specific process parameters are: 300g of sucrose core, fed by top spraying; air intake 230m 3 h -1 , the speed of the liquid supply pump is 2rpm, the air inlet temperature is 30-40°C, the material temperature is 25-35°C, and the atomization pressure is 0.20MPa; That is, 365 g of pellets loaded with nano-selenium were obtained. The pellets are regular and spherical, with a particle size of about 0.5 mm, uniform particle size distribution, and a red surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com