High-flow hydraulic ceramic plunger pump

A ceramic plunger, high flow technology, used in piston pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problem of affecting the service life of seals, cannot be effectively and timely It can meet the needs and other problems well, and achieve the effect of guaranteeing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

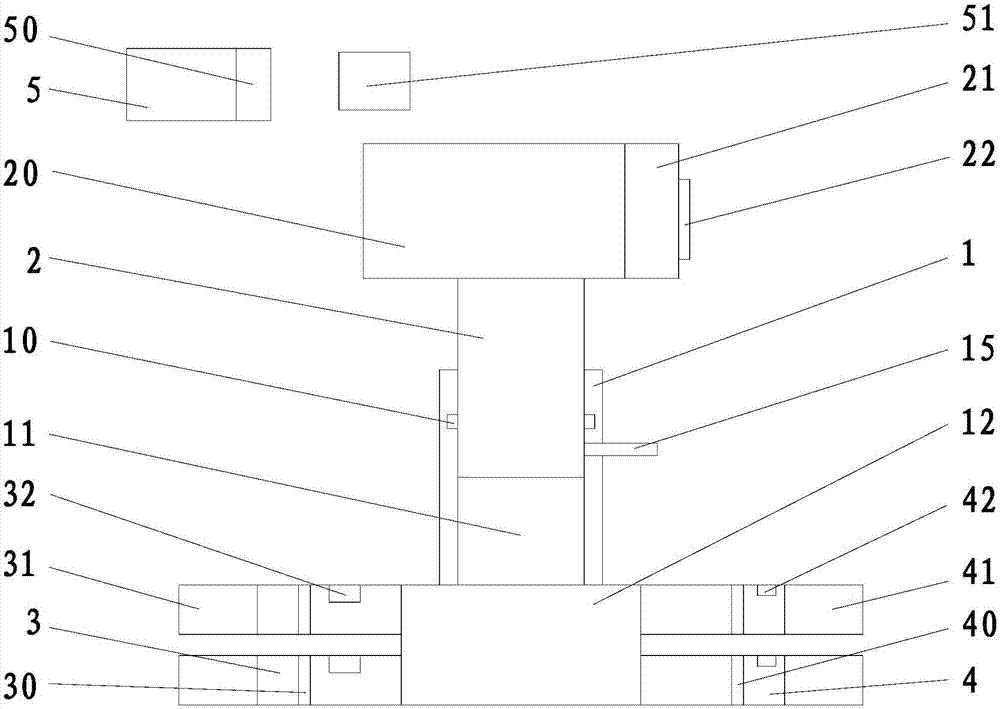

[0015] refer to figure 1 , a large-flow hydraulic ceramic plunger pump of the present invention, comprising a hydraulic device 20, a ceramic plunger 2, a pump body 1, a main chamber 12, a sealing ring 11, a feed pipe 3, a discharge pipe 4, and a control processing device 5 , the pump body 1 is provided with a mounting hole 10, a sealing ring 11 is provided in the mounting hole 10, the ceramic plunger 2 is mounted on the mounting hole 10, the ceramic plunger 2 is connected with the hydraulic device 20, and the hydraulic device 20 is connected with the control processing device 5, the pump body 1 is provided with a main chamber 12, the main chamber 12 communicates with the installation hole 10, and the pump body 1 is equipped with a number of feed pipes 3 and a number of discharge pipes The pipe 4, the feed pipe 3 and the discharge pipe 4 are all in communication with the main chamber 12, the feed pipe 3 is provided with a first one-way valve 30, and the discharge pipe 4 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com