Heat pump drying device and application method thereof

A technology of heat pump drying and drying method, which is applied in the direction of drying gas arrangement, heat pump, drying, etc., which can solve the problems of small application range of drying, easy damage of dried materials, incomplete evaporation, etc., and achieve expansion of application range and flexibility, Improvement of flexibility and reliability, and improvement of functional diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

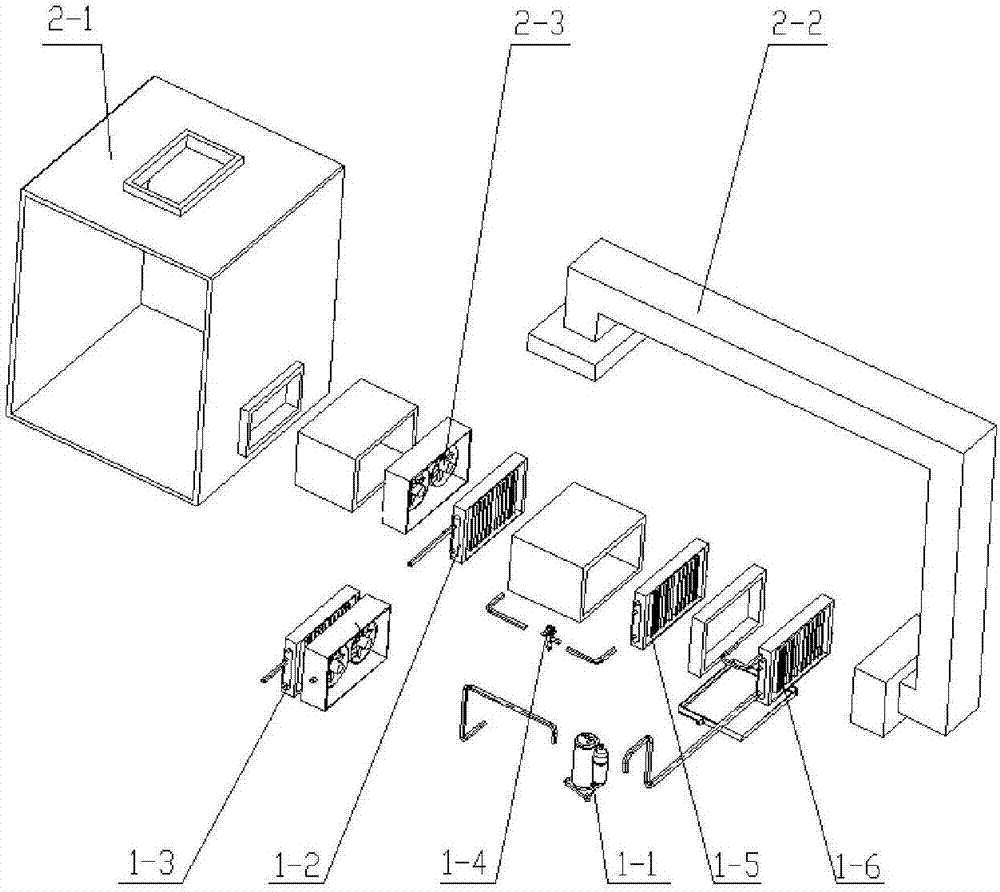

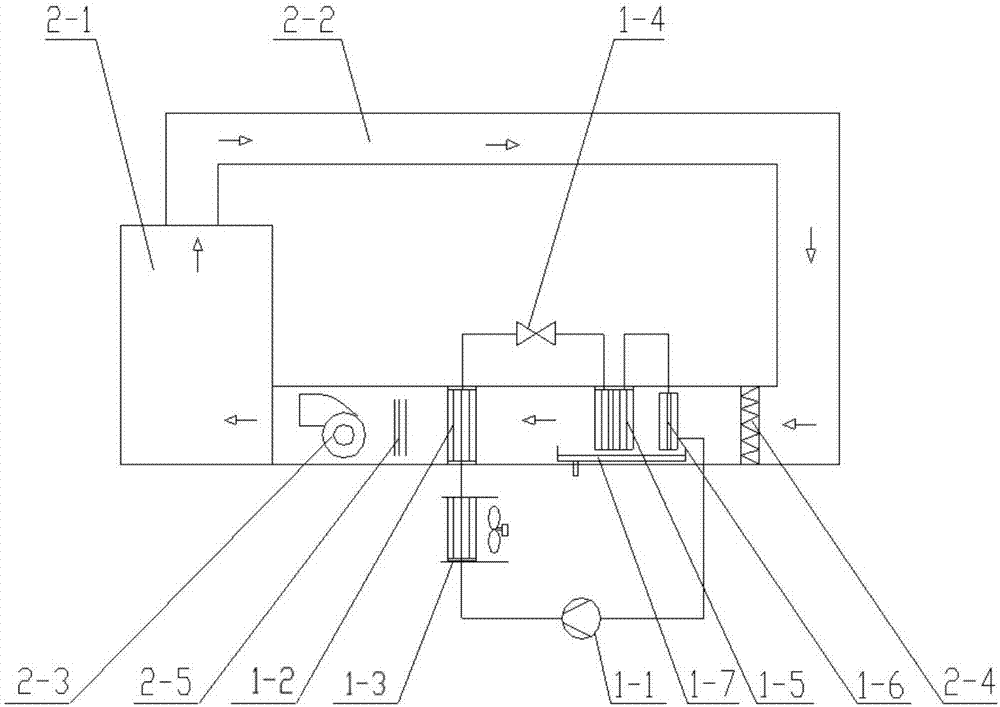

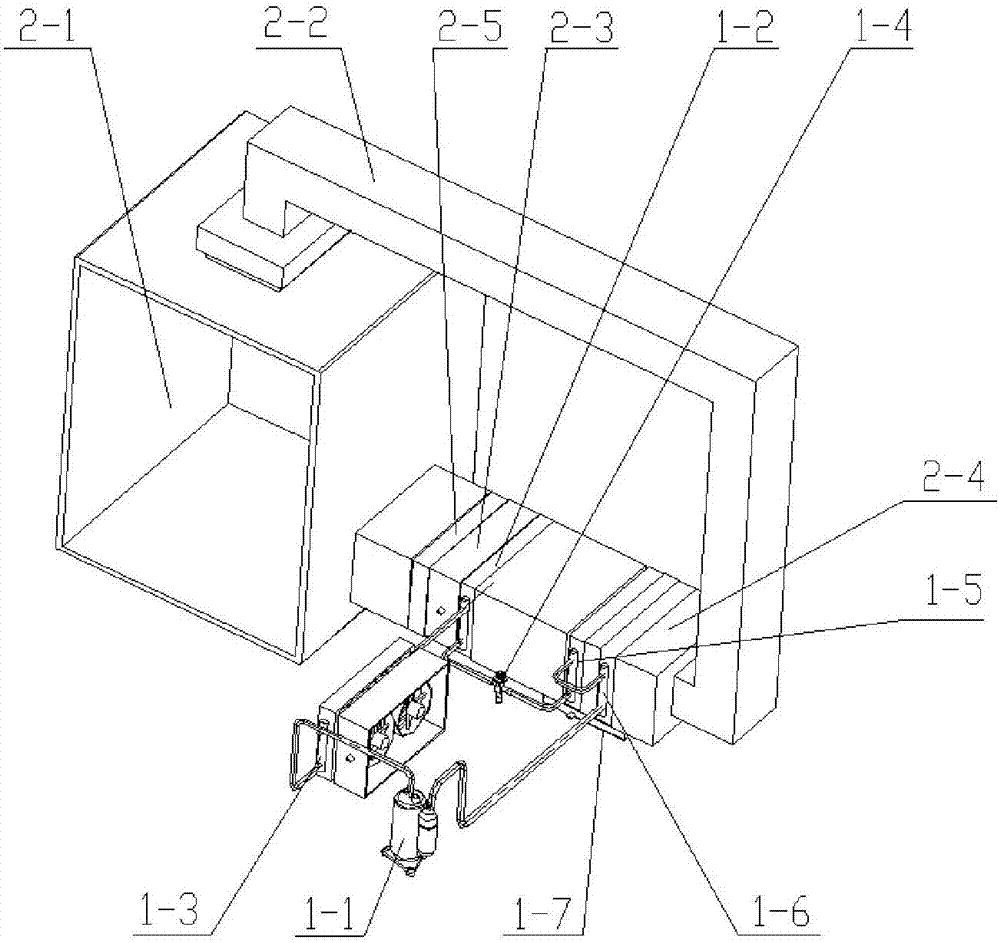

[0031] A heat pump drying device of the present invention can be found in the attached figure 1 - attached Figure 5 , consists of two parts, the heat pump circulation subsystem and the drying circulation subsystem. The heat pump circulation subsystem includes: a compressor (1-1), a heat regulating device (1-3), a condenser (1-2), a throttle (1-4), an evaporator (1-5) , Precooling heat exchanger (1-6). The drying cycle subsystem includes: a drying chamber (2-1), an air duct (2-2), and a drying fan (2-3).

[0032] In the heat pump cycle subsystem, the exhaust port of the compressor (1-1) is connected to the inlet of the heat regulating device (1-3) through the pipeline parts, and the outlet of the heat regulating device (1-3) is connected to the condenser ( 1-2) The inlet is connected, the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com