A high-temperature vacuum wind tunnel test chamber and diffuser integral structure with sliding thermal compensation function and sliding thermal compensation method

A high-temperature vacuum and wind tunnel test technology, applied in the field of wind tunnel, to achieve the effect of increasing the contact area, simplifying the structure design, and reducing the thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

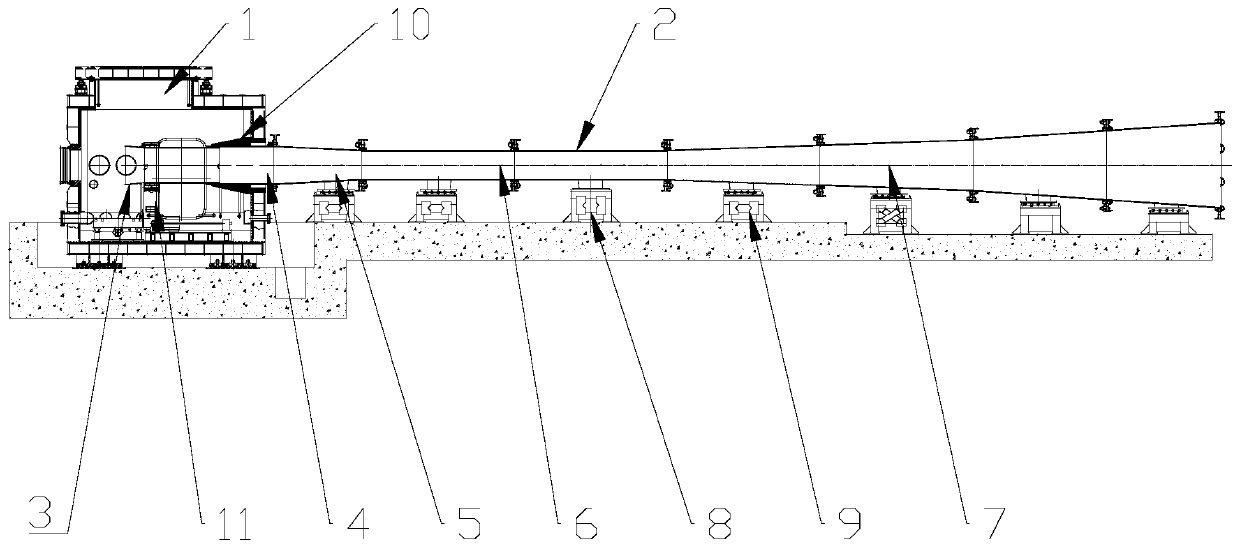

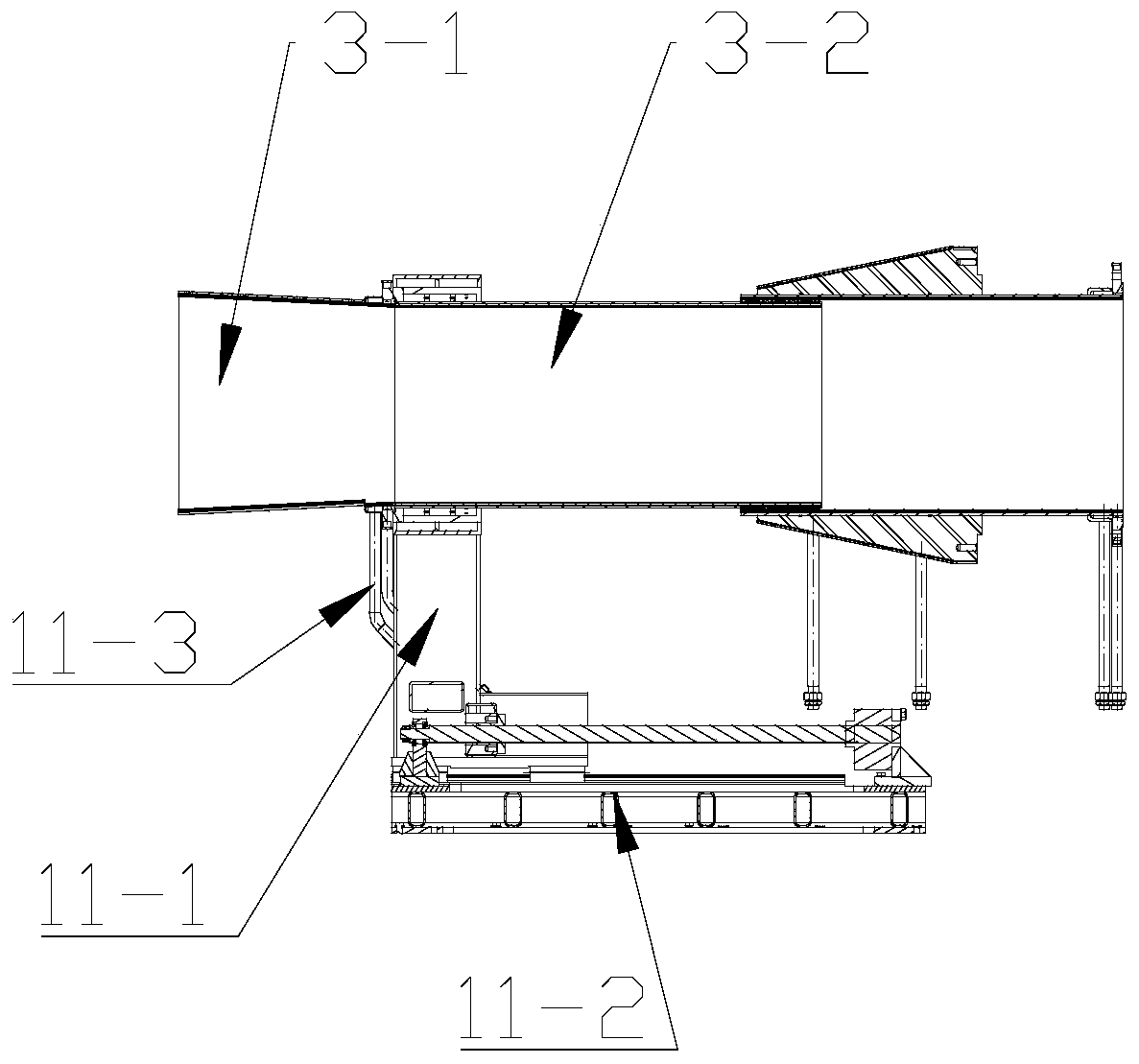

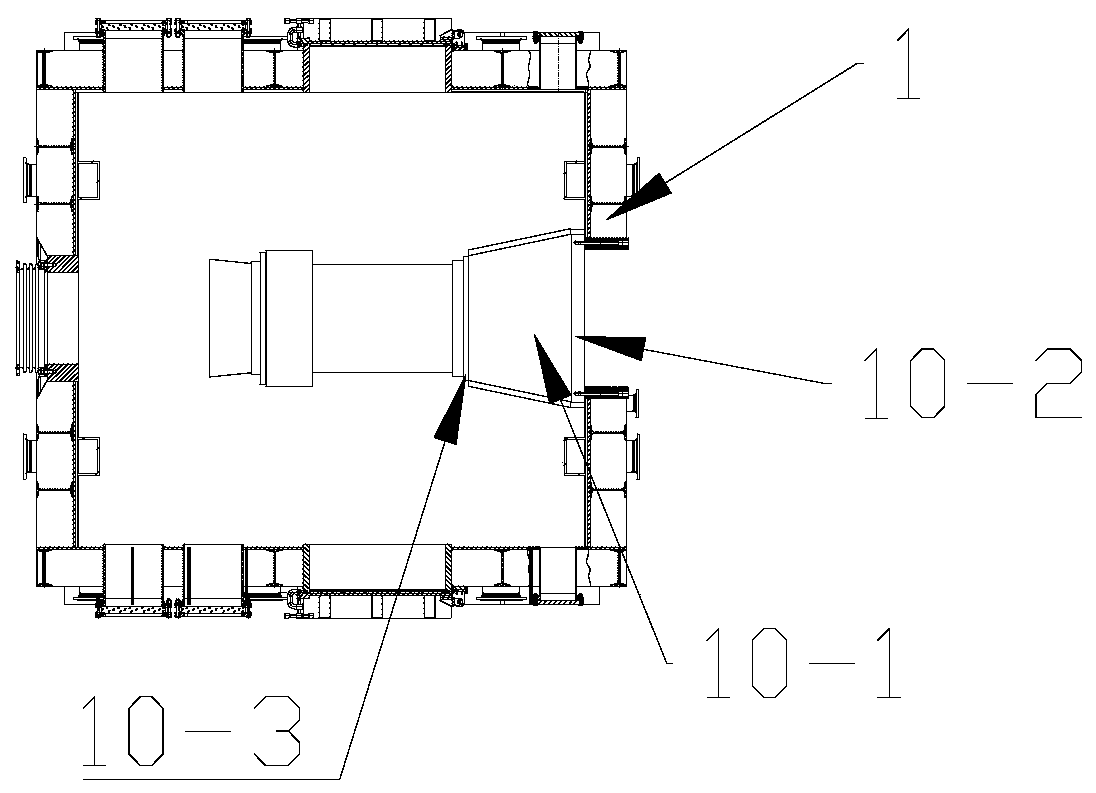

[0035] The present invention provides a high-temperature vacuum wind tunnel test chamber with a sliding thermal compensation function, an overall structure of a diffuser and a sliding thermal compensation method, which overcomes the deficiencies of the prior art, and provides a thermal compensation scheme for a high-temperature wind tunnel diffuser, Solve the problem of thermal compensation in the large gas flow wind tunnel test chamber in the harsh thermal environment of long time, high temperature and large heat flow. The structural design of fixed support in the middle of the diffuser and sliding at both ends is adopted to reasonably distribute the amount of thermal expansion. Depending on the thermal environment, different thermal compensation methods are used at different locations. Upstream: The contact area between the cabin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com