Quasi-static test device and method for base-free reinforced concrete column

A technology of reinforced concrete column and test device, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of large amount of concrete pouring, waste, and high manufacturing cost, and achieve the effects of saving consumption, convenient pouring, and saving experiment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

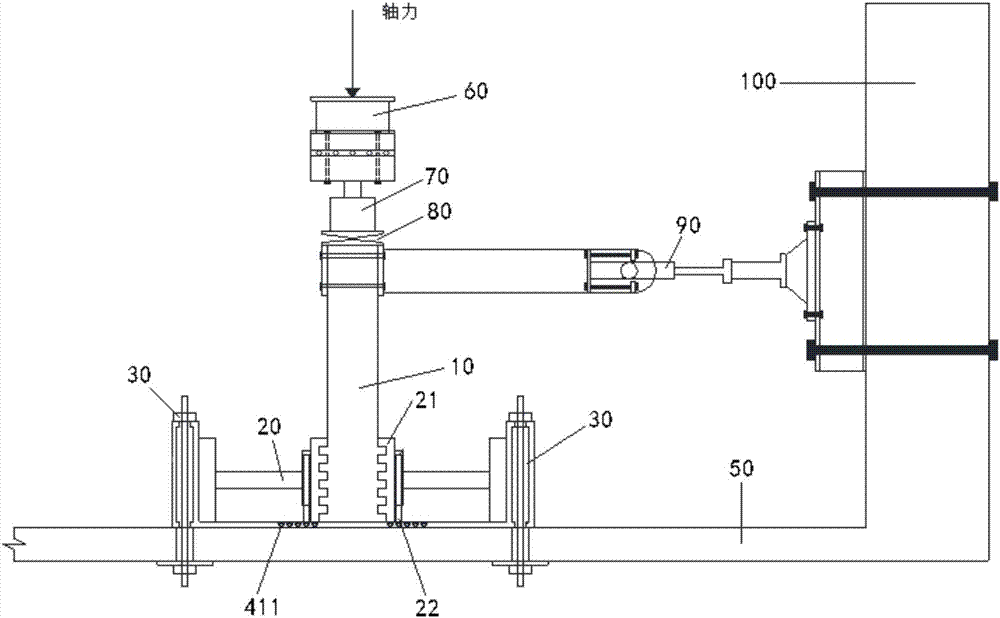

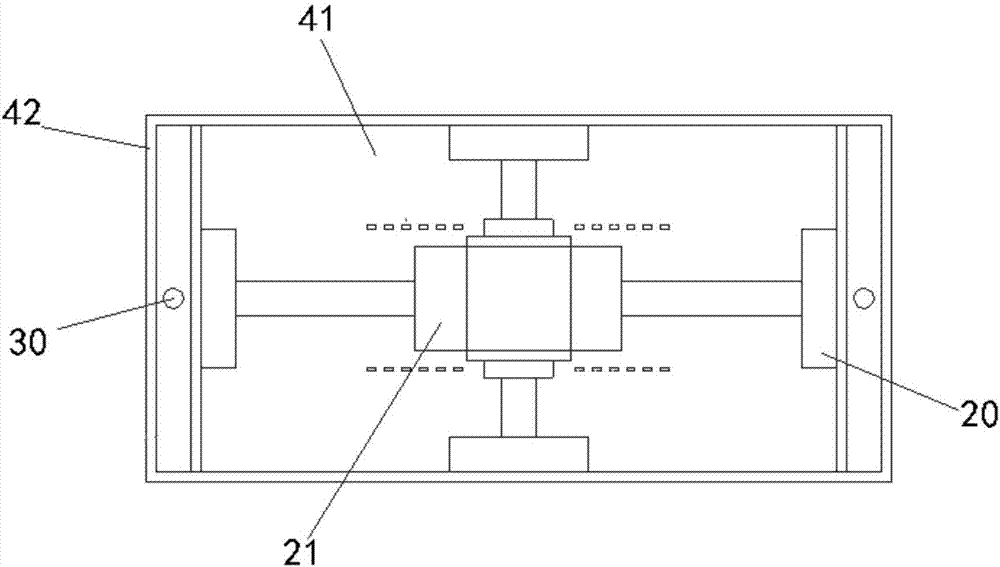

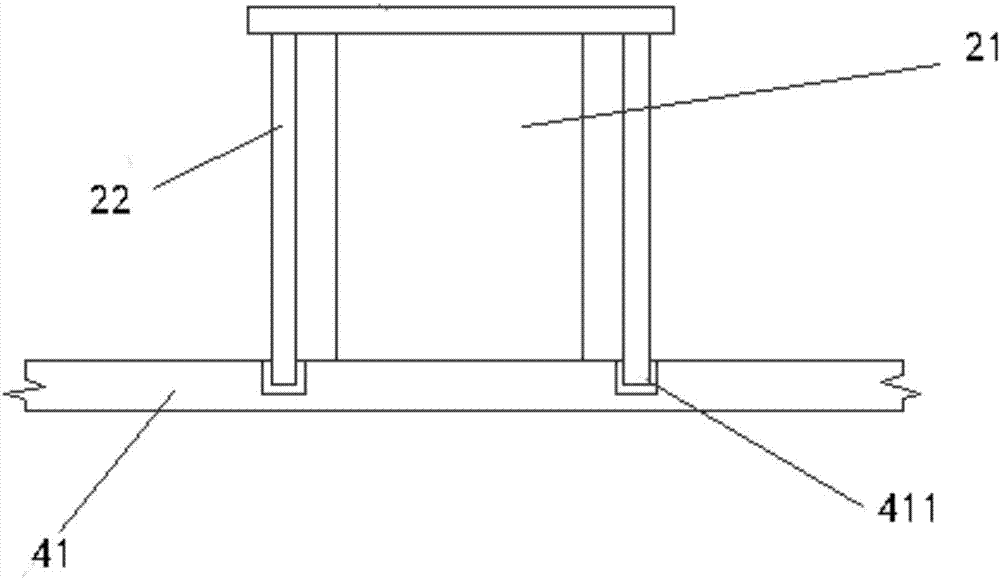

[0026] The main process of the pseudo-static test device for the reinforced concrete column 10 is to arrange the reinforced concrete column 10 to be tested vertically, rigidly fix the bottom of the column, and generate pressure through the vertical pressure device 70 fixed on the reaction beam 60. For vertical compressive stress, through the steel hinge 80 device, a uniform load is applied to the reinforced concrete column 10 specimens according to the test design axial compression ratio. The reinforced concrete column 10 is connected to the laboratory reaction wall 100 through the actuator 90 , and the actuator applies a horizontal reciprocating force to the reinforced concrete column 10 to generate a displacement cycle at the top of the reinforced concrete column 10 . Record the required data with corresponding measuring instruments.

[0027] Compared with the traditional method of setting a huge base at the bottom of the reinforced concrete column 10 to achieve the predeter...

Embodiment 2

[0035] The main process of the traditional pseudo-static test device for reinforced concrete column 10 is to arrange the reinforced concrete column 10 to be tested vertically, rigidly fix the bottom of it, and generate pressure through the vertical pressure device fixed on the reaction beam. For the vertical compressive stress, through the steel hinge device, a uniform load is applied to the reinforced concrete column 10 specimens according to the test design axial compression ratio. The reinforced concrete column 10 is connected to the reaction wall of the laboratory through an actuator, and the actuator applies a horizontal reciprocating force to the reinforced concrete column 10 so that the top of the reinforced concrete column 10 produces a displacement cycle. Record the required data with corresponding measuring instruments.

[0036] The structural cost of setting the base at the bottom of the reinforced concrete column 10 is too high, and the waste is too serious. This e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com