In-situ nanoindentation/nanoscratching test device based on bionic piezoelectric driving

A nano-indentation and testing device technology, applied in measurement devices, testing material hardness, instruments, etc., can solve the problems of relying on foreign imports of instruments, lack of test content, and single test methods, and achieve rich test content, deformation/displacement/displacement/displacement, etc. The effect of load/rate controllable and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

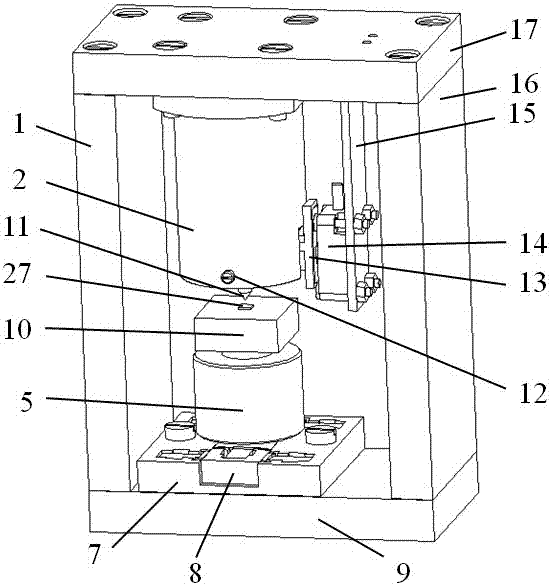

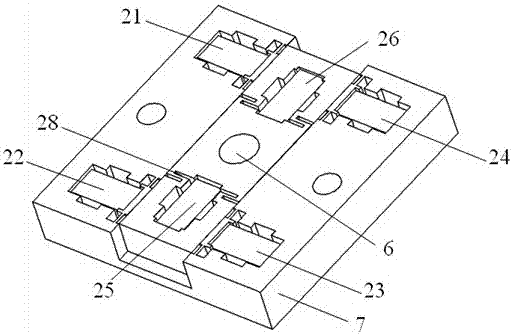

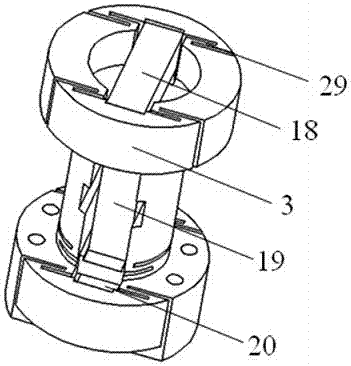

[0017] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0018] see Figure 1 to Figure 5 As shown, the in-situ nano-indentation / scribing test device based on bionic piezoelectric drive of the present invention includes a precision drive unit, a signal detection and control unit, a clamping unit, a connection unit and a support unit, a precision drive unit and a signal detection and The control unit is installed on the supporting unit through the clamping unit and the connecting unit. The precision drive unit is: piezoelectric stacks A, B, C18, 19, 20 drive the mover 3 in the vertical direction by acting on the vertical flexible hinge 29, and piezoelectric stacks D~I21~26 act on the horizontal flexible hinge 29. The hinge 28 drives the mover 8 in the horizontal direction, wherein the mover 3 in the vertical direction is rigidly connected with the connecting plate 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com