A battery continuous cooling process with vertical transfer function

A cooling process and transfer function technology, applied in sustainable manufacturing/processing, lead-acid batteries, battery pack components, etc., can solve the problems of low battery cooling efficiency, uncompact battery cooling process, etc. The effect of reducing floor space and reasonable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

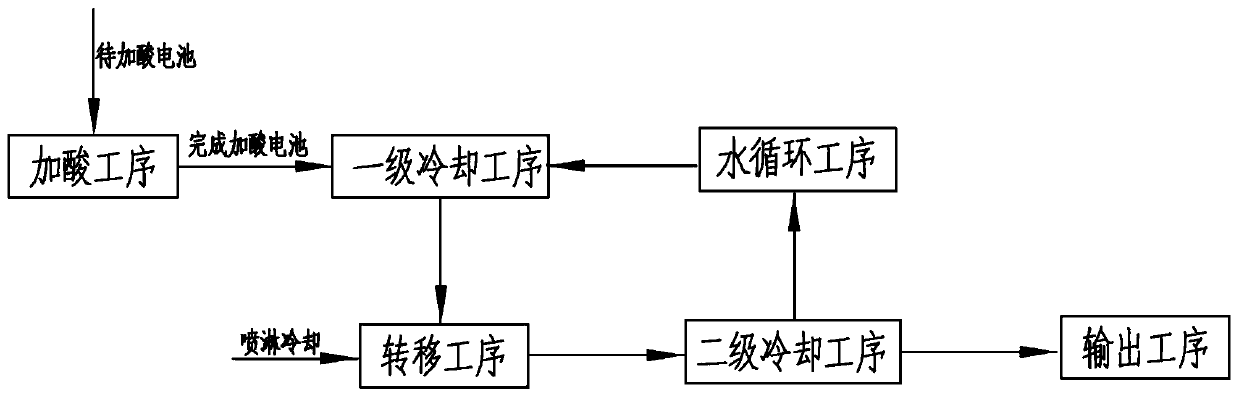

[0064] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a battery continuous cooling process with vertical transfer function, including the following production steps:

[0065] a. Acid addition process, acid treatment is carried out to the battery to be added acid;

[0066] b. The primary cooling process, placing the battery that has completed the acid treatment in step a in the first water cooling channel for rapid water cooling while transporting, and transporting the battery to the station to be transferred;

[0067] c. Transfer process, the battery that has completed the first-level rapid water cooling at the transfer station in step b is transferred down to the push station through the lifting device (232) along the transfer channel (231), and passed through during the transfer process. The spray device (233) sprays and cools the side of the battery;

[0068] d...

Embodiment 2

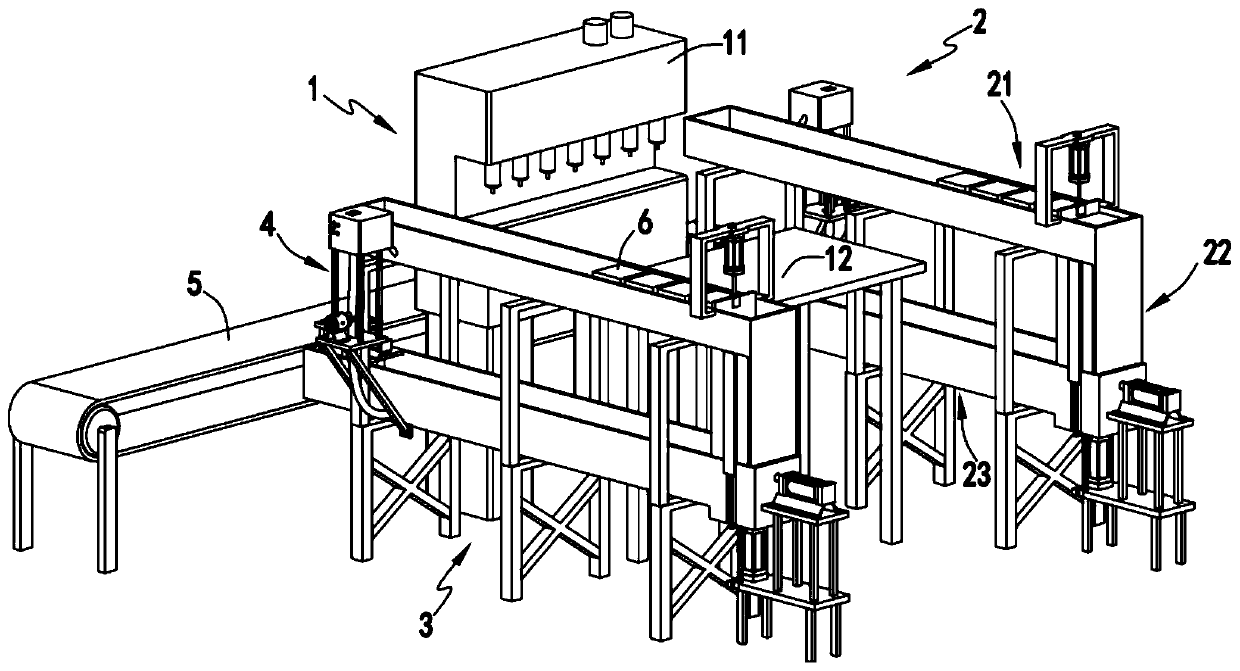

[0079] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a lead-acid battery high and low transfer transmission cooling equipment includes an acid adding part 1, the acid adding part 1 is used to add acid to the battery 6; a first cooling delivery part 2, the first cooling delivery part 2 is arranged on one side of the acid addition part 1; and a second cooling delivery part 3 is arranged on the other side of the acid addition part 1;

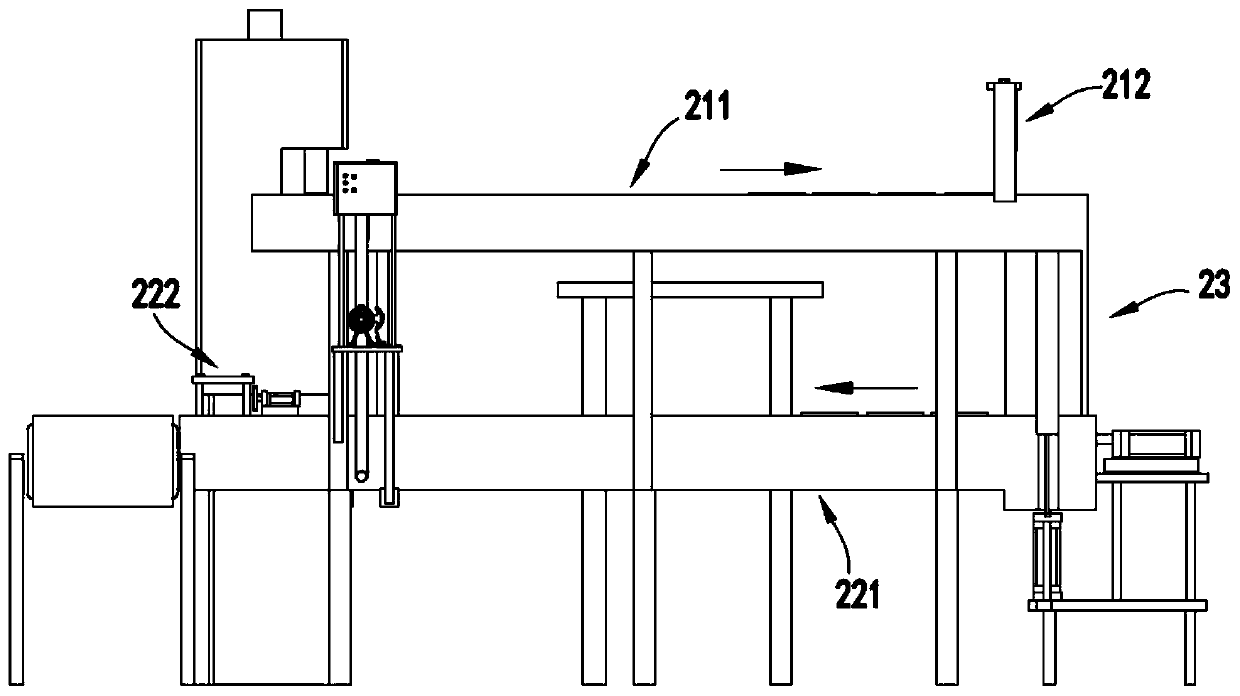

[0080] Both the first cooling conveying part 2 and the second cooling conveying part 3 are used to cool the battery 6 that has completed acid addition while conveying, and the first cooling conveying part 2 and the second cooling conveying part 3 both include an upper conveying Mechanism 21, be arranged on the following conveying mechanism 22 below the upper conveying mechanism 21 and be arranged between the upper conveying mechanism 21...

Embodiment 3

[0102] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between the third embodiment and the second embodiment is: further, a cooling transfer device 4 is also provided between the upper conveying mechanism 21 and the lower conveying mechanism 22, and the cooling transfer device 4 is used to transfer the lower conveying mechanism The water in 22 is transferred to the upper conveying mechanism 21 and the water is cooled during the transfer process. The cooling transfer device 4 includes a water pump 41 and a cooling tower 42. The suction pipe 43 of the water pump 41 communicates with the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com