Plane-revolution reversible glasses

A plane rotating and flipping mirror technology, which is applied in medical science, eye testing equipment, eye exerciser, etc., can solve the problems of inconvenient operation of hand-held flip mirrors, uncertain lens distances, and unfixed distances, etc., to achieve improved The effect of adjusting sensitivity and inspection accuracy, precisely adjusting the number of cycles, and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

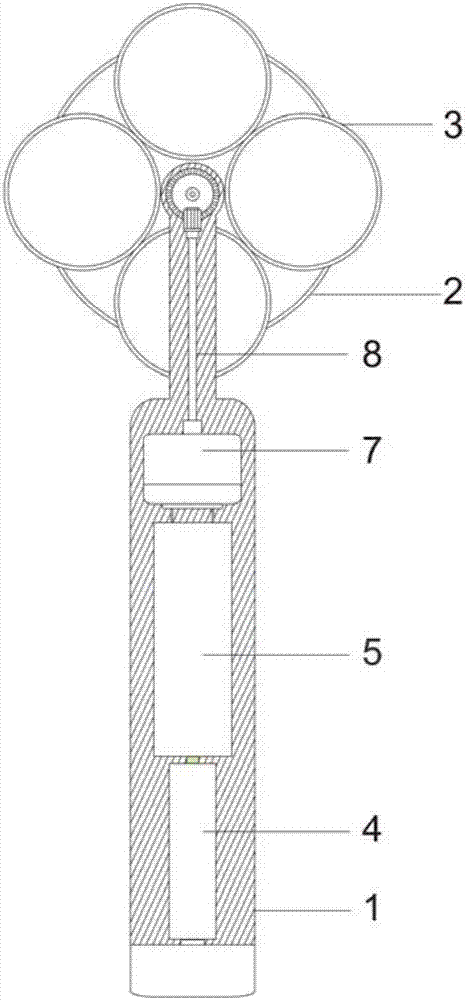

[0033] figure 1 The back sectional view of a kind of plane rotating flip mirror prepared for embodiment 1;

[0034] figure 2 The front sectional view of a kind of planar rotating flip mirror prepared for embodiment 1;

[0035] Figure 7 A side sectional view of a kind of planar rotating flip mirror designed for embodiment 1; wherein A is an overall view, and B is an enlarged view of a transmission mechanism;

[0036] like figure 1 and figure 2 As shown, a plane rotating flip mirror includes a handle 1 and a lens frame 2. The handle handle is a thin shell cavity structure, and a transmission system and a control system are arranged inside. The lens frame is connected to the transmission system and is arranged on At the upper end of the handle, the lens frame is parallel to the axial plane of the handle. The control system controls the transmission system to drive the lens frame to rotate on this plane. The lens frame is composed of four lens frames 3, and the centers of ...

Embodiment 2

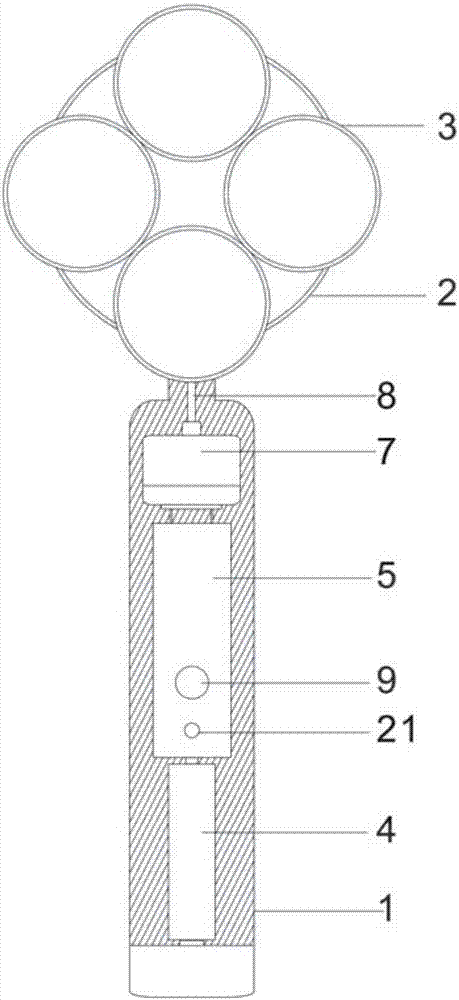

[0041] image 3 A kind of plane rotating flip mirror prepared for embodiment 2;

[0042] Figure 4 A schematic diagram of the use of a plane rotating flip mirror prepared in Example 2;

[0043] like image 3 and Figure 4 As shown, a plane rotating flip mirror includes a handle 1 and a lens frame 2. The handle handle is a thin shell cavity structure, and a transmission system and a control system are arranged inside. The lens frame is connected to the transmission system and is arranged on At the upper end of the handle, the lens frame is parallel to the axial plane of the handle. The control system controls the transmission system to drive the lens frame to rotate on this plane. The lens frame is composed of four lens frames 3, and the centers of the four lens frames are located at the center of the lens frame. On the same circle of , the plane rotation is the circular movement of the four lenses around the center of the lens frame;

[0044] Preferably, the control syste...

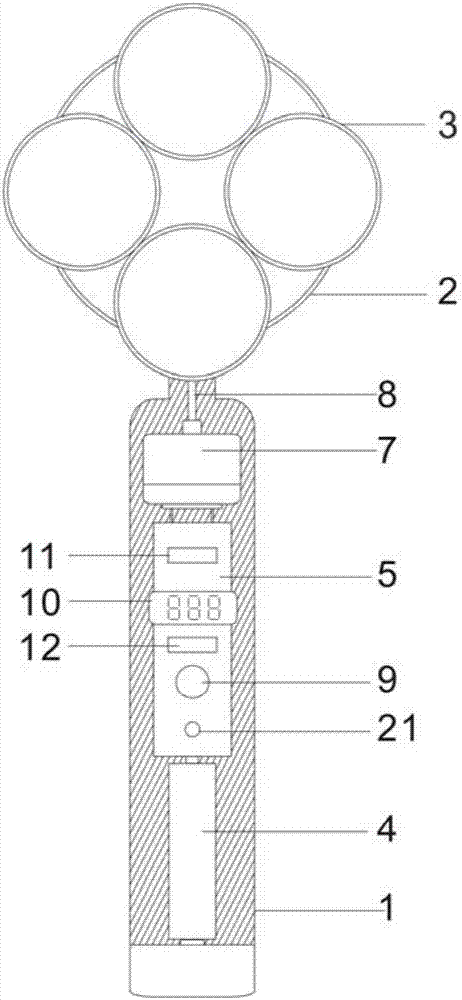

Embodiment 3

[0052] Figure 5 A schematic diagram of the use of a plane rotating flip mirror designed for embodiment 3;

[0053] A plane rotating reversible mirror, comprising a handle 1 and a lens frame 2, the handle is provided with a transmission system and a control system, the lens frame is connected to the transmission system and is arranged on the upper end of the handle, the axial plane between the lens frame and the handle Parallel, the control system controls the transmission system to drive the lens frame to rotate on this plane, the lens frame is composed of four lens frames 3, the centers of the four lens frames are located on the same circle centered on the center of the lens frame, and the plane rotates into four lenses Circular motion around the center of the lens frame;

[0054] Preferably, the control system includes a power switch 21, a control switch 9, a PCB control board 5, a stepper motor 7 and a power supply 4, and the PCB control board is also provided with a timi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com