Automatic hook feeding assembling device

An assembly device and hook feeding technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of limited assembly precision and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

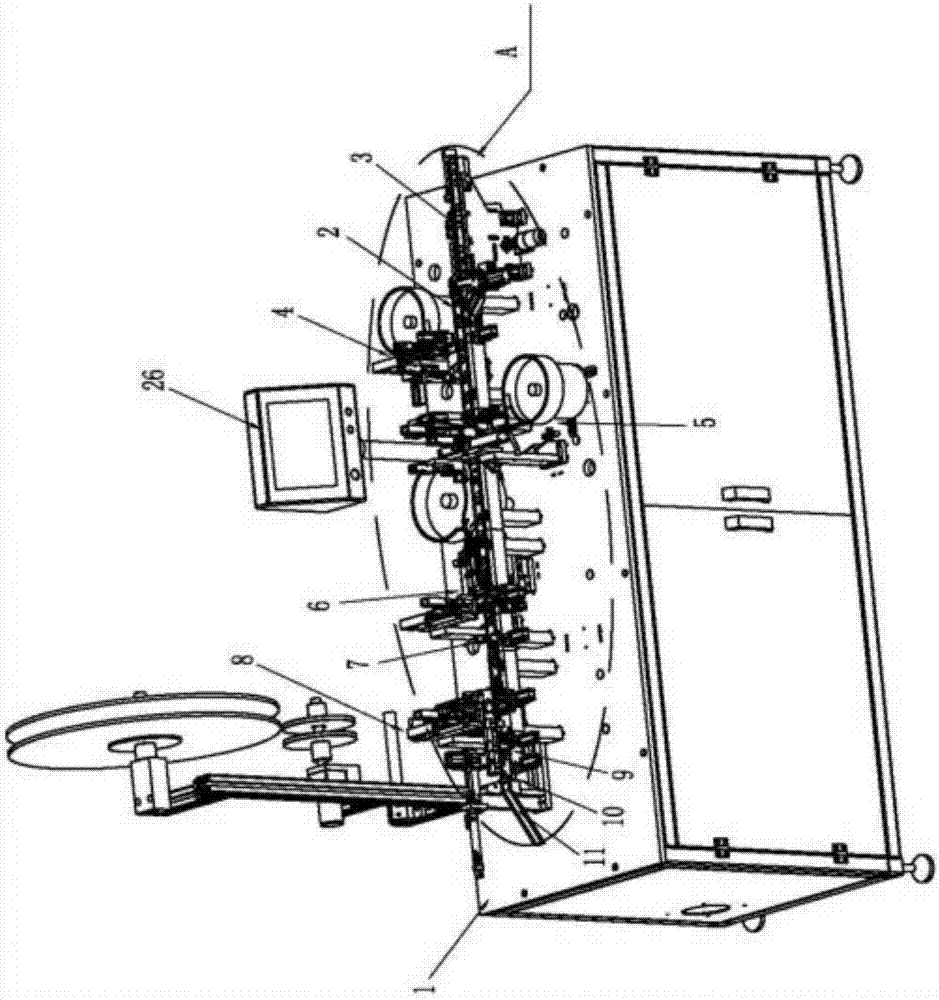

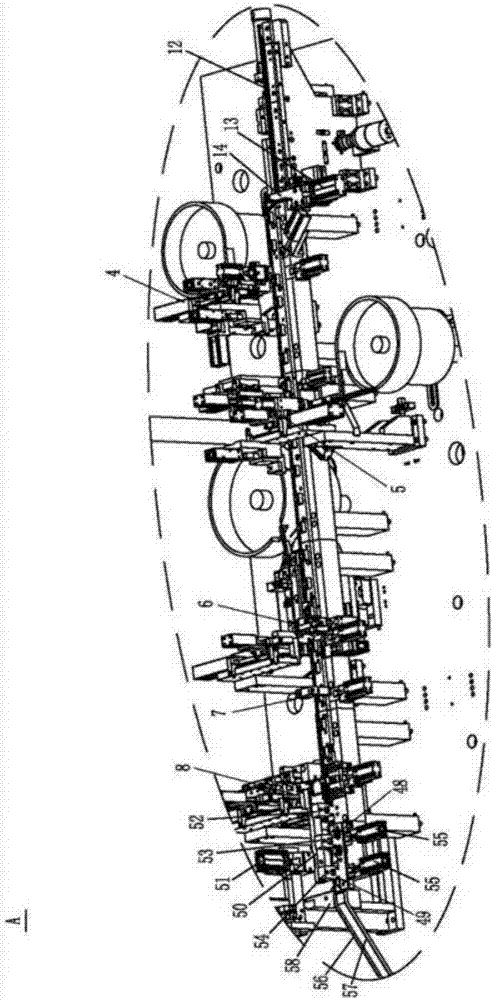

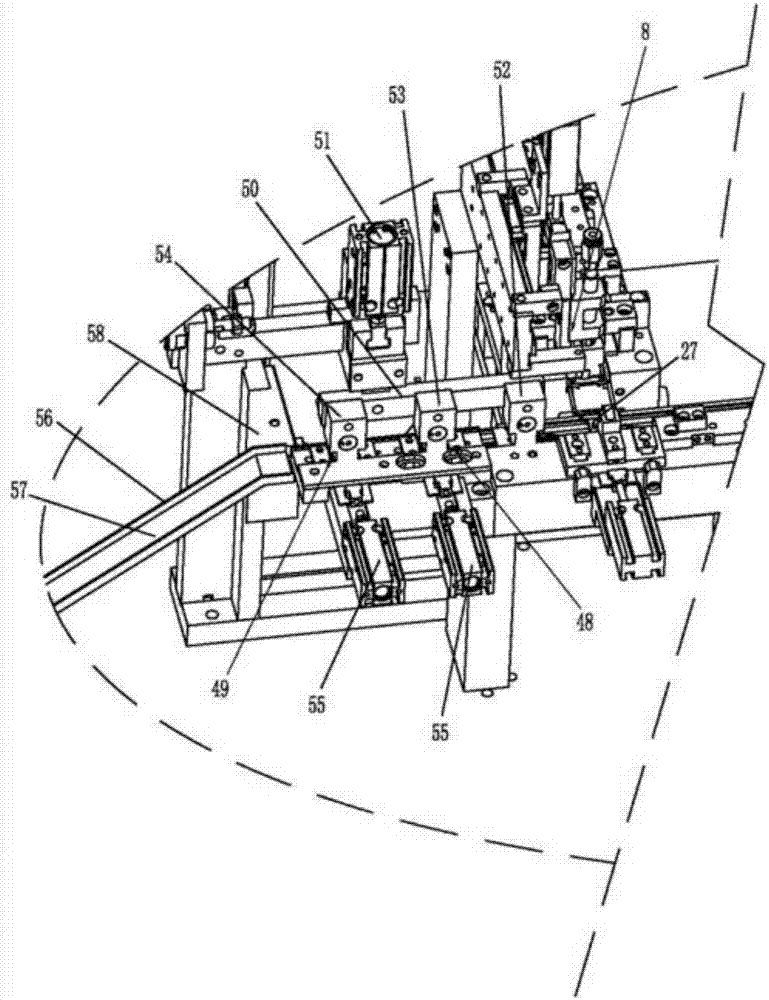

[0062] Please refer to Figure 1 to Figure 14 As shown, it shows the specific structure of the embodiment of the present invention, which is mainly aimed at the subsequent spring installation, slider installation, hook installation, iron shell installation and interspersed design in the manufacturing process of the semi-finished product (ie, the rubber core with the terminal) There are no restrictions on the above-mentioned semi-finished product formation process, such as the inspection process, defective elimination, etc.

[0063] In this example, if Figure 1 to Figure 5 As shown, this kind of TF card connector assembly equipment includes a frame 1, a main control unit 26 and a conveying track 2 arranged on the frame 1, and a semi-finished product feeding unit 3, Spring feeding assembly unit 4, slider feeding assembly unit 5, hook feeding assembly unit 6, missing installation detection unit 7, iron shell feeding assembly unit 8, lock card return card testing unit 9, defecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com