Pipe-shaped workpiece rough shape cutting device

A workpiece and tubular technology, applied in the field of tubular workpiece cutting device, can solve the problems of complex structure of the cutting device and low accuracy of workpiece length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

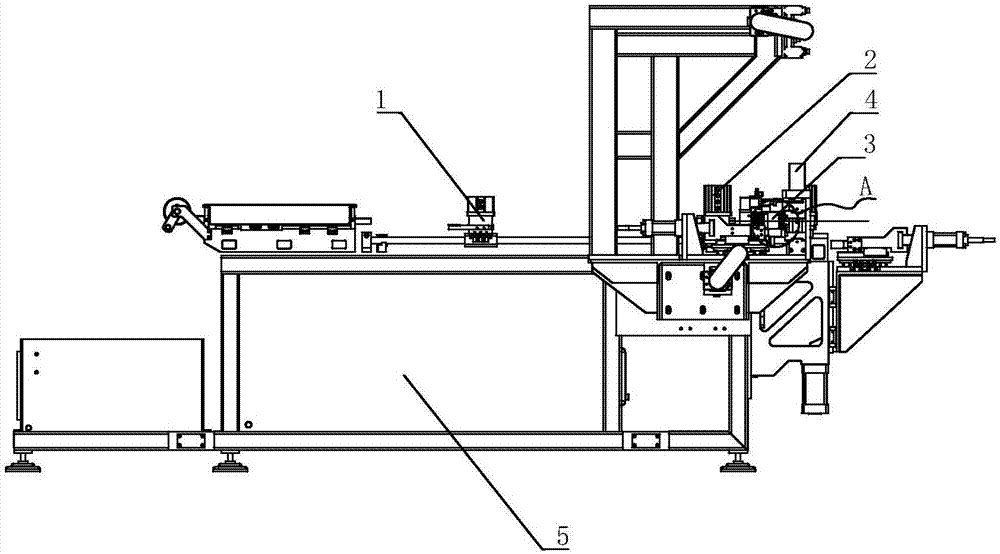

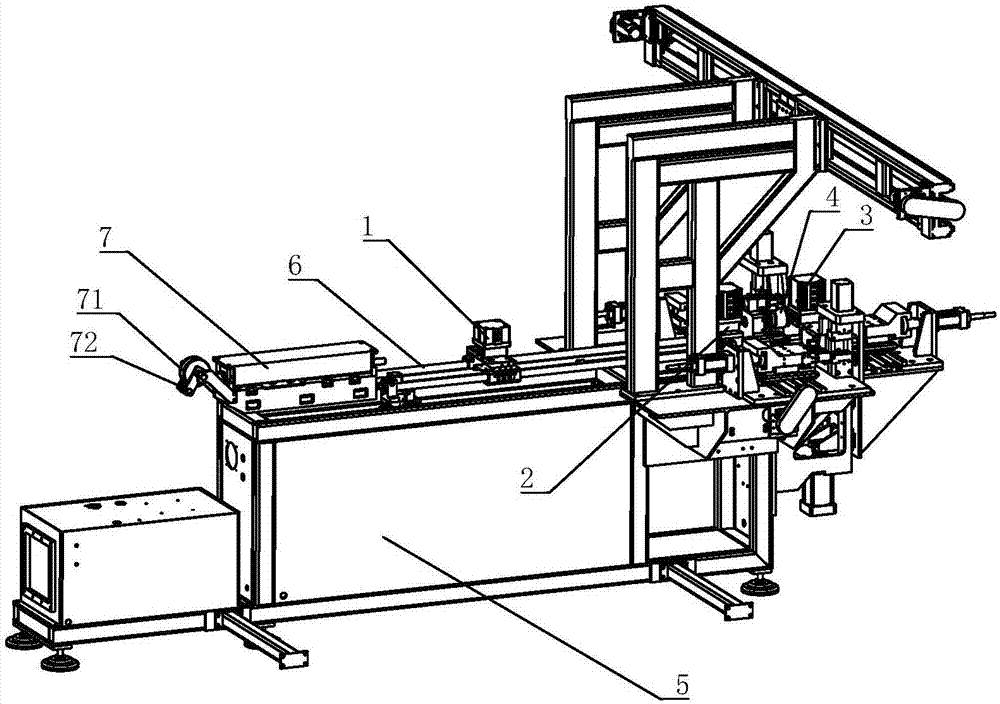

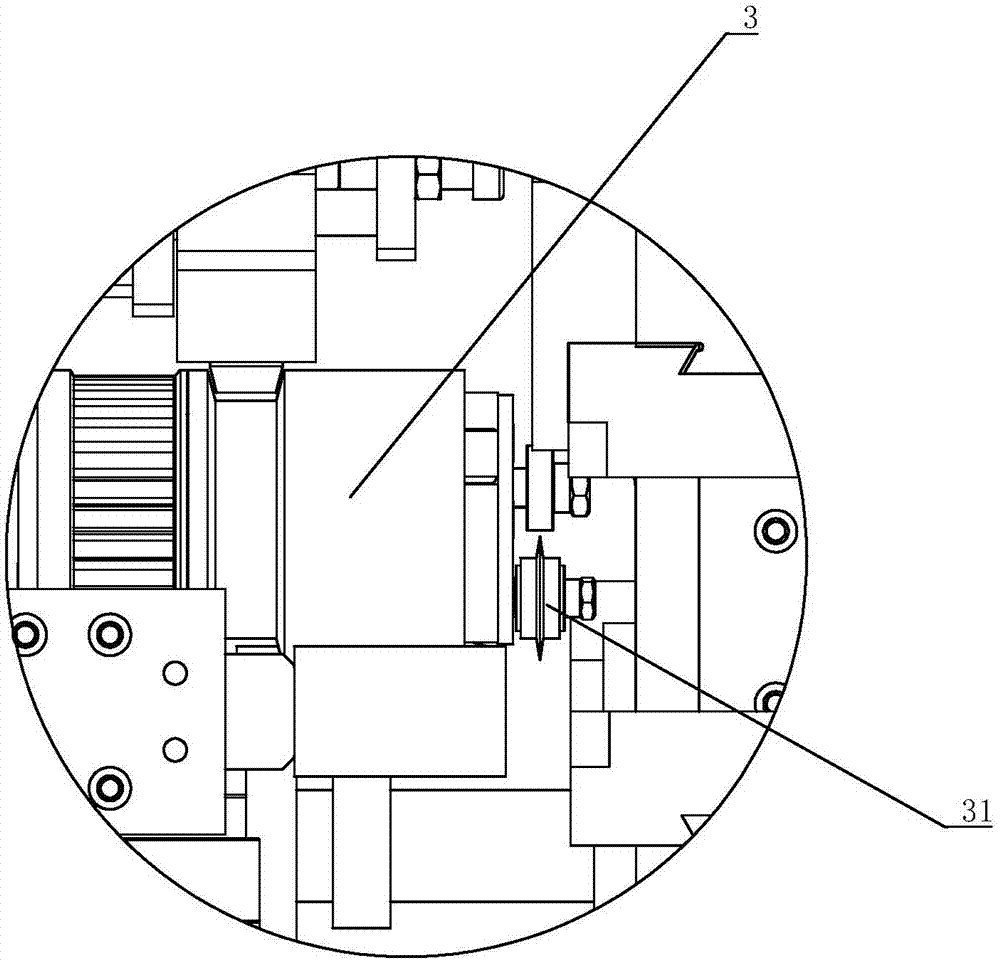

[0017] refer to Figure 1 to Figure 3 , a tubular workpiece cutting device of the present invention includes a frame 5 .

[0018] Frame 5 is provided with feeding clamp 1, clamping clamp 2, pipe cutting cutter head 3 and breaking clamp 4 in sequence, feeding clamping die 1, clamping die 2, pipe cutting cutter head 3 and breaking clamp The dies 4 are all arranged on the same axis; this axis is the axis of the tubular workpiece, and the same axis of each component can realize a good docking of the workpiece. The feeding clamp 1 is movably connected with the frame 5 and can move along the axis direction, and is used to send the workpiece to the processing area formed by the clamping clamp 2, the pipe cutting head 3 and the breaking clamp 4. The feeding clamp 1 It is connected with a feeding driving mechanism that drives its movement; the feeding drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com