Combined pump-jet propeller

A propulsion and combined technology, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of high noise, energy loss, low propulsion efficiency, etc., and achieve low radiation noise, low thrust loss, and high propulsion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

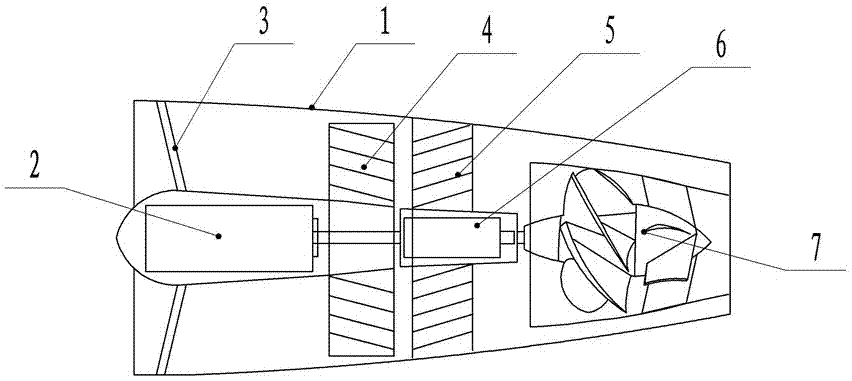

[0009] The combined pump-jet propeller includes an external conduit 1, the external conduit 1 is in a shrinking shape, and the two ends of the external conduit 1 are respectively water inlet and water outlet. The device includes a pump spray rotor 4, a pump spray stator 5 and a pump spray motor 2, the pump spray motor 2 is fixed in the external conduit 1 through four fixed wings 3, the pump spray motor 2 is connected to the pump spray rotor 4 at the rear, and the pump spray rotor 4 The pump spray stator 5 is arranged at the rear for rectification, and the pump spray stator 5 is connected to the external conduit 1. The spray pump impeller motor 6 is arranged at the center of the pump spray stator 5, and the spray pump impeller motor 6 is connected to the water spray propulsion pump 7.

[0010] The present invention adopts the combination of pump-jet propulsion and water-jet propulsion, which avoids the disadvantages of common propeller propulsion such as poor cavitation resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com