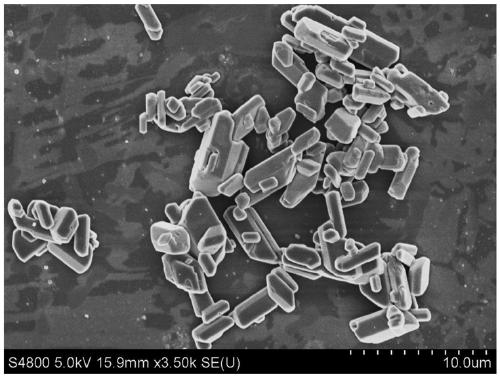

A kind of preparation method of short prismatic α-calcium sulfate hemihydrate powder

A technology of calcium sulfate hemihydrate and calcium sulfate dihydrate, applied in chemical instruments and methods, calcium/strontium/barium sulfate, calcium/strontium/barium compounds, etc., can solve the problem of difficult to provide mechanical strength and biological activity of bone repair parts. Weakness, poor mechanical properties and other problems, to achieve the effect of easy industrial production, easy process control, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

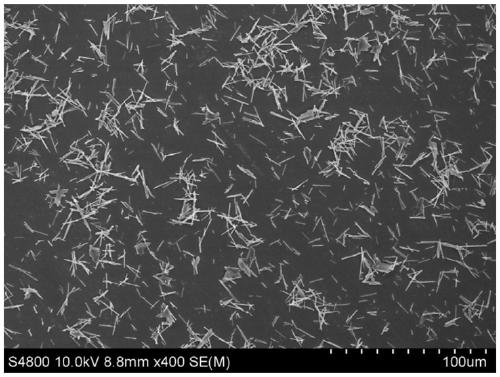

[0051] A preparation method of short prismatic α-calcium sulfate hemihydrate powder, the steps are as follows:

[0052] Prepare 2mol / L Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 Aqueous solution, Ca(NO 3 ) 2 Alcohol / water volume ratio in the ethanol solution is 1:1; Open the external circulation rotating packed bed, adjust the rotating speed to 2500rpm; Open the feed pump, the Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 The aqueous solution is simultaneously transported to the external circulation rotating packed bed for crystallization reaction, the feeding rate of the two salt solutions is controlled at 550mL / min, and the temperature of the reaction system is controlled at 25°C; after the crystallization reaction is completed, the rotating packed bed is closed, and the generated precursor slurry is The materials were filtered, washed, and dried to obtain the precursor powder; 1g of citric acid and 5g of aluminum nitrate were dissolved in 500mL of deionized...

Embodiment 2

[0056] A preparation method of short prismatic α-calcium sulfate hemihydrate powder, the steps are as follows:

[0057] Prepare 2mol / L Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 Aqueous solution, Ca(NO 3 ) 2 Alcohol / water volume ratio in the ethanol solution is 1:1; Open the external circulation rotating packed bed, adjust the rotating speed to 2500rpm; Open the feed pump, the Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 The aqueous solution is simultaneously transported to the external circulation rotating packed bed for crystallization reaction, the feeding rate of the two salt solutions is controlled at 550mL / min, and the temperature of the reaction system is controlled at 25°C; after the crystallization reaction is completed, the rotating packed bed is closed, and the generated precursor slurry is The materials were filtered, washed, and dried to obtain the precursor powder; 0.025g of citric acid was dissolved in 500mL of deionized water, dissolved in ult...

Embodiment 3

[0061] A preparation method of short prismatic α-calcium sulfate hemihydrate powder, the steps are as follows:

[0062] Prepare 2mol / L Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 Aqueous solution, Ca(NO 3 ) 2 Alcohol / water volume ratio in the ethanol solution is 1:1; Open the external circulation rotating packed bed, adjust the rotating speed to 2500rpm; Open the feed pump, the Ca(NO 3 ) 2 ethanol solution and (NH 4 ) 2 SO 4 The aqueous solution is simultaneously transported to the external circulation rotating packed bed for crystallization reaction, the feeding rate of the two salt solutions is controlled at 550mL / min, and the temperature of the reaction system is controlled at 25°C; after the crystallization reaction is completed, the rotating packed bed is closed, and the generated precursor slurry is The materials were filtered, washed, and dried to obtain the precursor powder; 0.6g of succinic acid was dissolved in 500mL of deionized water, dissolved in ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com