A method for degrading p-nitrophenol reduction

A technology of stirring and dissolving p-nitrophenol, which is applied in chemical instruments and methods, reduced water/sewage treatment, chemical/physical processes, etc., can solve the problems of multi-level pore synthesis and increase the temperature, and achieve high reactive sites effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

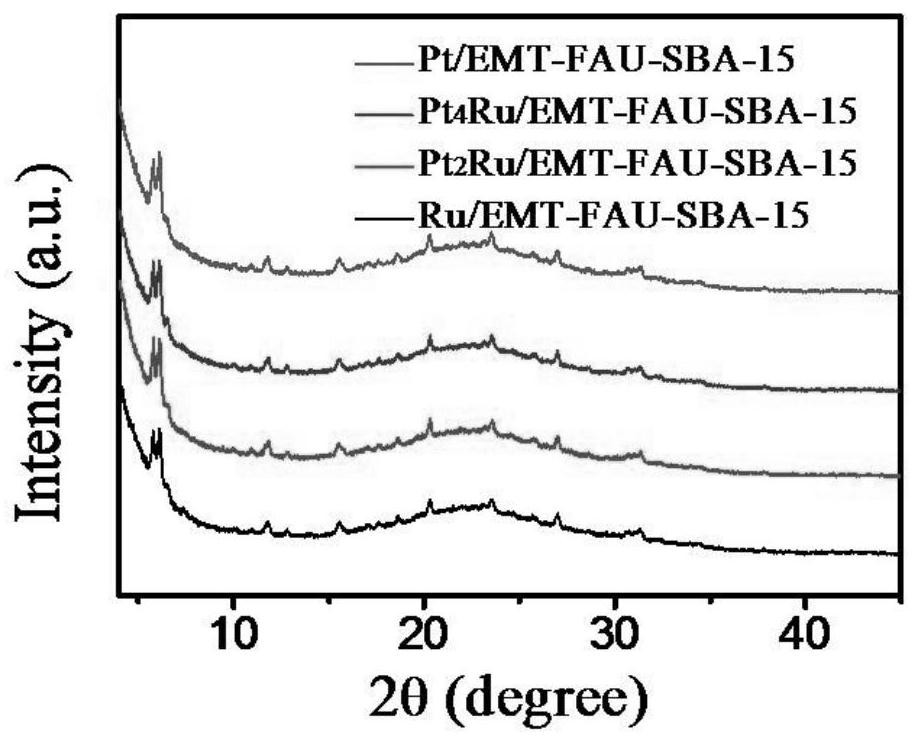

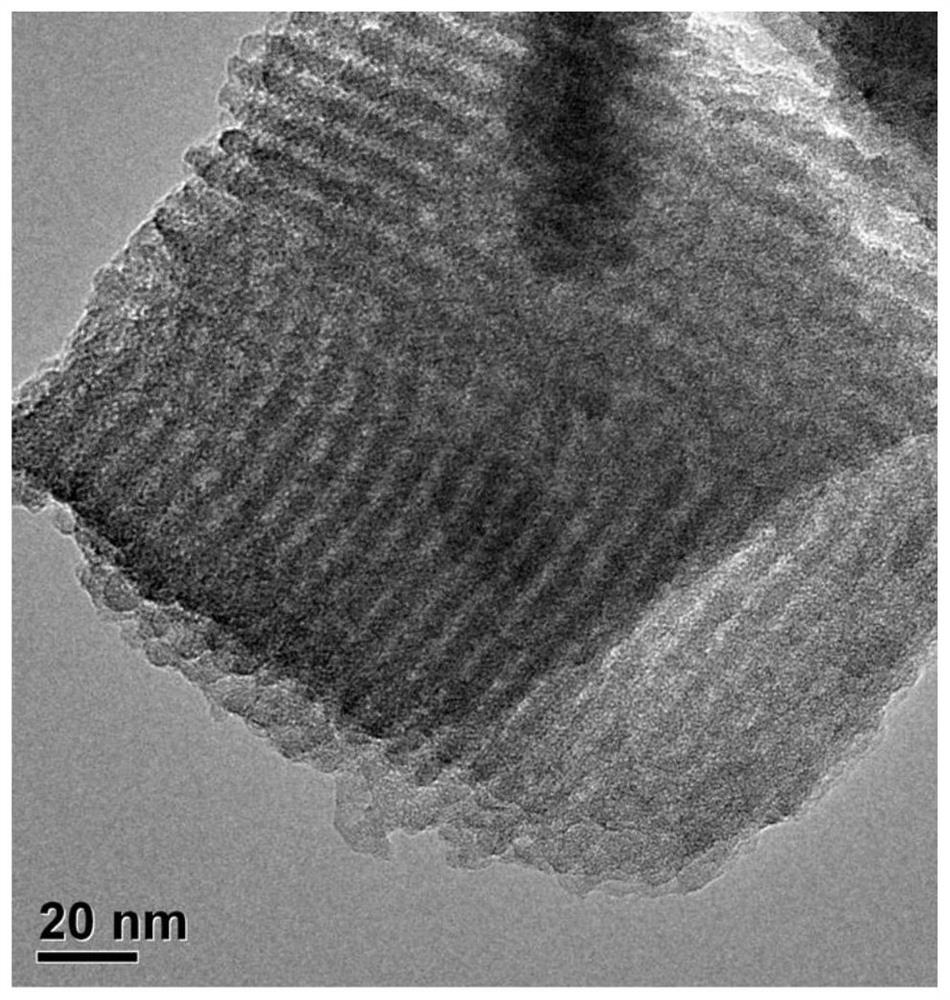

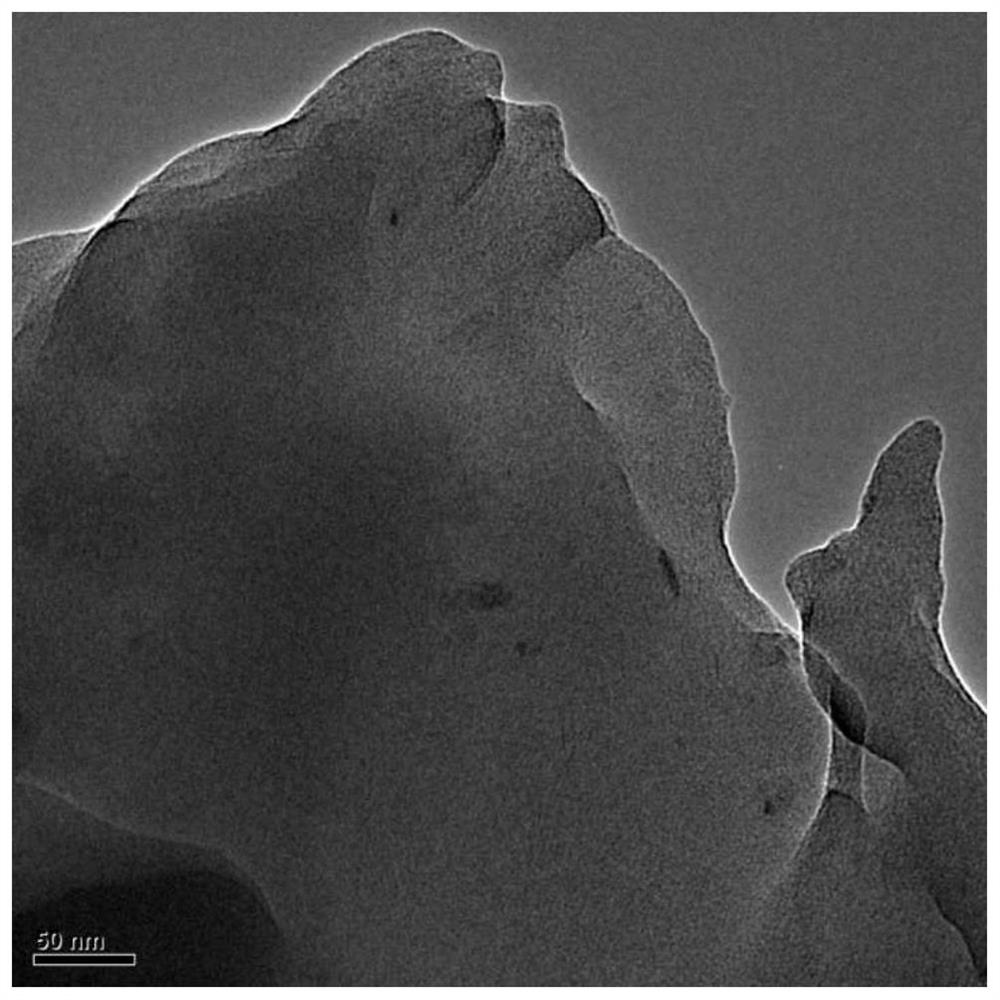

[0025] Pt 2 The preparation method of Ru / EMT-FAU / SBA-15 catalyst:

[0026] A. Add 0.35g sodium hydroxide, 1.04g sodium aluminate, 1.0g 18-crown-6, 0.034g sodium phosphate, 4.74g deionized water and 6.3g silica sol into the reaction kettle and stir at 25 degrees Celsius dissolved as solution I;

[0027] B. Add 0.12g 3-mercaptopropyltrimethoxysilane, 0.15g sodium hydroxide and 2g deionized water into the beaker and stir to dissolve, then add 1.8mL of H 2 PtCl 6 (100mol / L) and 0.9mL of RuCl 3 solution (100mol / L), as solution II;

[0028] C. Add solution II dropwise to solution I and stir for 3 hours, then age at 25 degrees Celsius for 24 hours, then transfer to a reaction kettle and crystallize at 100 degrees Celsius for 96 hours to obtain a PtRu / EMT-FAYU zeolite microcrystalline emulsion;

[0029] D. Add 2g of P123 organic matter to the hydrochloric acid solution to dissolve and disperse, add dropwise the tetraethyl orthosilicate of 4.28g and the PtRu / EMT-FAU zeolite microc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com