Recovery system for waste heat of raw gas from riser tube of coke oven

A waste heat recovery system and waste gas technology, applied in the heating of coke ovens, coke ovens, indirect heat exchangers, etc., can solve the problems of low energy consumption and low power consumption, and achieve high heat transfer performance and low power consumption for operation , the effect of small cycle magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

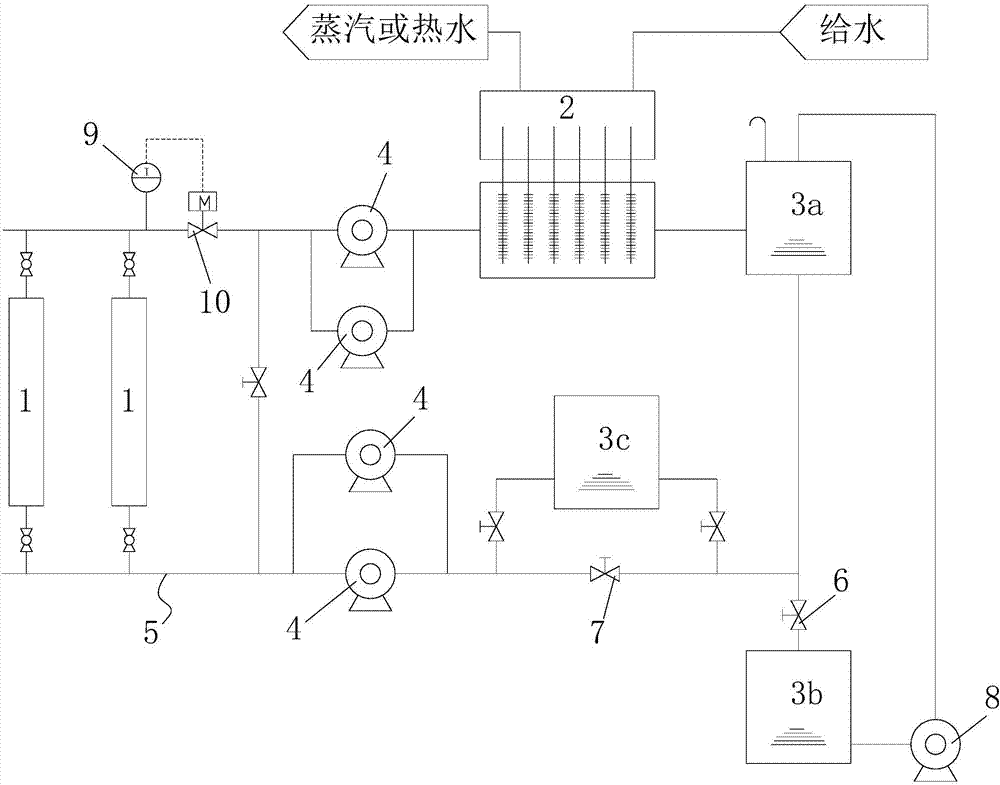

[0048] figure 1 It shows a specific embodiment of the coke oven riser raw gas waste heat recovery system of the present invention, which mainly includes a molten salt supply and delivery device, a first heat exchange device 1 and a second heat exchange device 2, wherein:

[0049] The molten salt supply and conveying device is used to provide molten salt and drive the molten salt to make a closed circulation flow.

[0050] The first heat exchange device 1 is arranged at the riser of the coke oven and is connected with the molten salt supply and delivery device. The raw gas heat exchange, so that the molten salt absorbs the heat of the raw gas in the rising tube of the coke oven.

[0051]The second heat exchange device 2 is also connected to the molten salt supply and delivery device, and the molten salt exchanges heat with the working medium in the second heat exchange device when circulating to the second heat exchange device, for use in Heat is absorbed by the molten salt a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com