Fusible alloy connecting structure and use method thereof for building construction

A technology of fusible alloy and connection structure, which is applied in the direction of building structure, building, building structure support, etc., can solve the problems of lower load-bearing capacity of the support, poor connection stability, loose aluminum alloy support, etc., to achieve good connection stability and improve Load-bearing strength, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

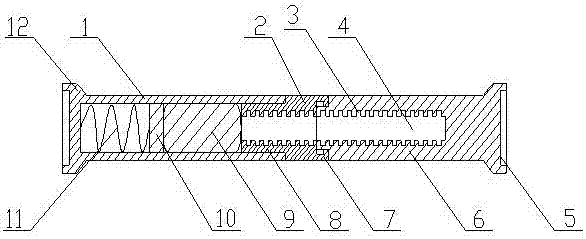

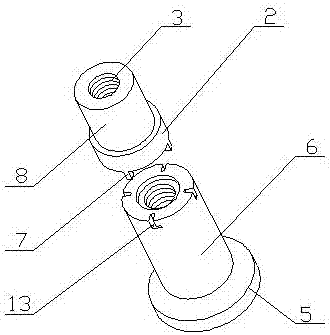

[0016] A fusible alloy connection structure for building construction in the present invention is realized in this way. It consists of a main device and an auxiliary device. The main device consists of a metal pipe (1), a locking sleeve (2), an annular groove (3), and a locking buckle ( 7), connecting sleeve (8), temperature control fusible alloy (9), piston (10), compression spring (11) and limit platform (12), the limit platform (12) is placed in the metal tube (1) On one end, the outer wall of the metal tube (1) is threaded, the piston (10) is placed in the metal tube (1), and is connected with the limit platform (12) through the compression spring (11), and the connecting sleeve (8 ) placed in the other end of the metal tube (1), the inner wall of the connecting sleeve (8) is equally spaced with a plurality of annular grooves (3), and the temperature-controlling fusible alloy (9) is placed in the metal tube (1), And it is located between the piston (10) and one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com