Assembly jig and assembly leak-detection system

A technology for assembling fixtures and leak testing, which is used in manufacturing tools, workpiece clamping devices, and measuring the acceleration and deceleration rates of fluids. , the effect of eliminating the transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

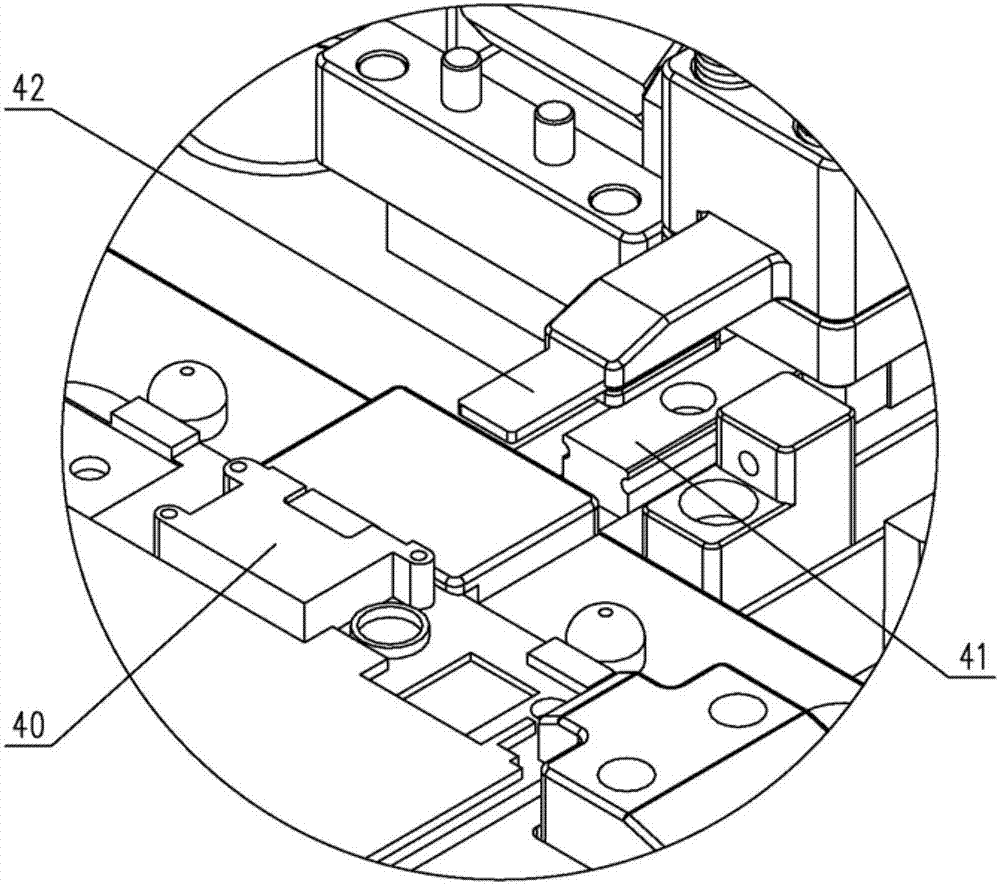

[0035] The invention also discloses an assembled leak detection system, including waterproof leak detection equipment and a jig for assembling product 1 and product 2; the waterproof leak detection equipment forms a test air path through the air pipe and air channel, and passes through the detection and comparison of the test air. The pressure of the road and the standard pressure output the test results. Product one 37 is a mobile phone screen module, and product two 40 is a speaker module.

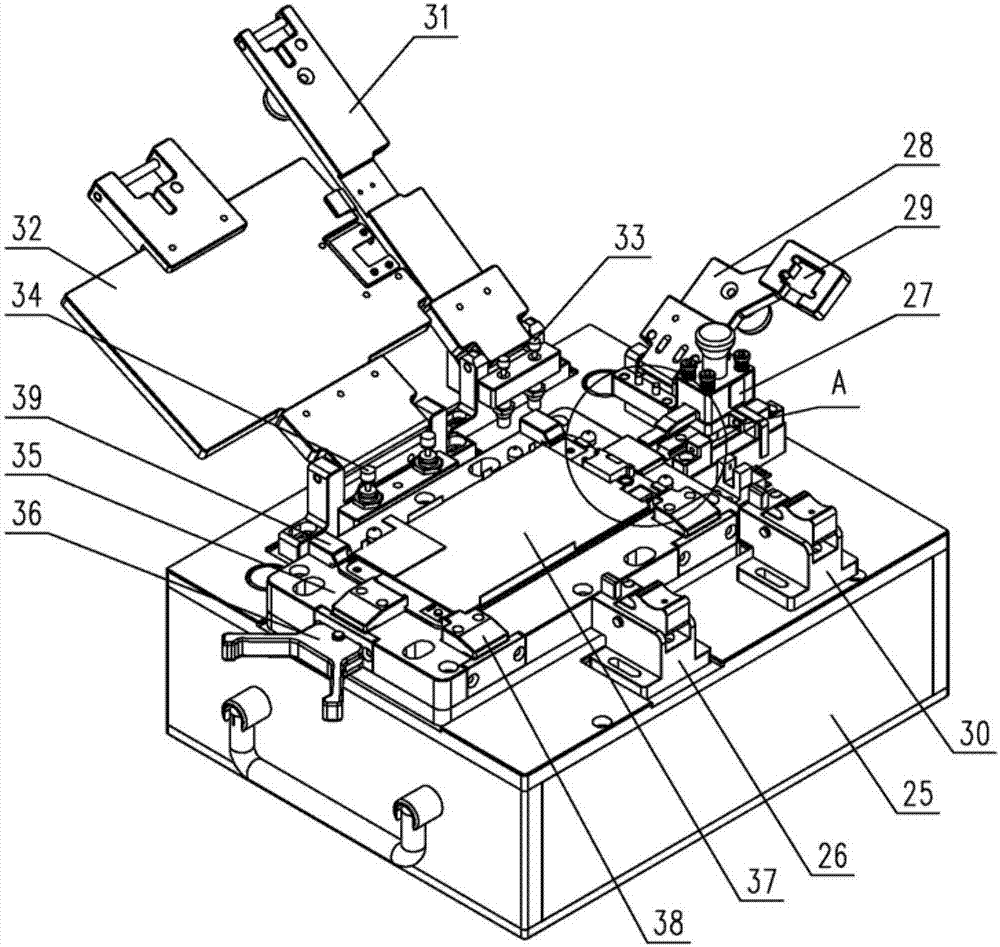

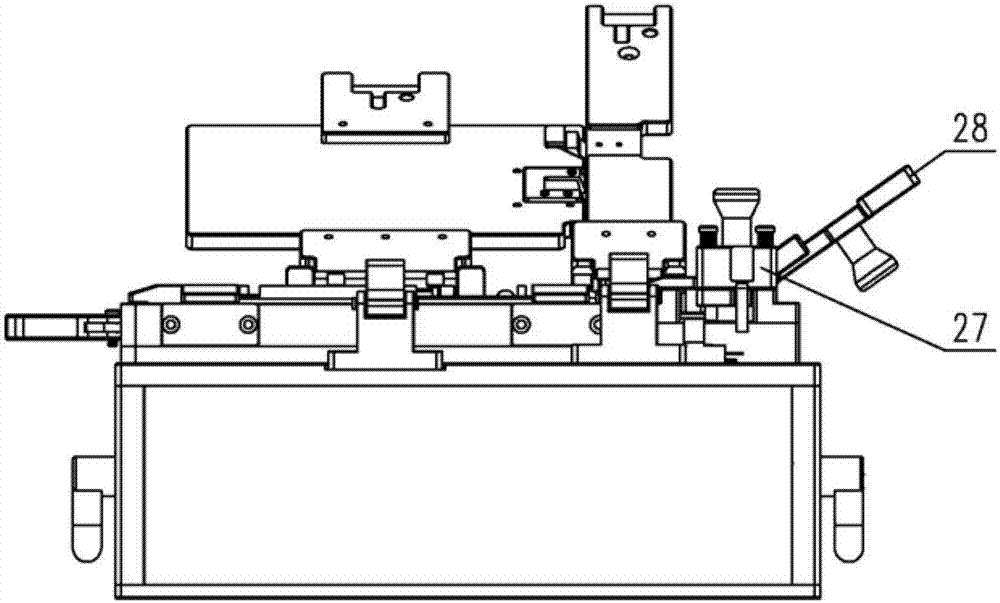

[0036] Such as Figures 1 to 5 As shown, an assembly jig includes a workbench 25, on which a group loading platform 35, a sliding platform 27, a movable pressing piece 42, a locking screw cover 28, a lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com