A Simulating System and Experimental Method for Synchronous Grouting in Shield Tunneling Method

A technology of synchronous grouting and simulation system, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of limited on-site guidance, and achieve the convenience of experimental teaching, reasonable structure design, and pressure value exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

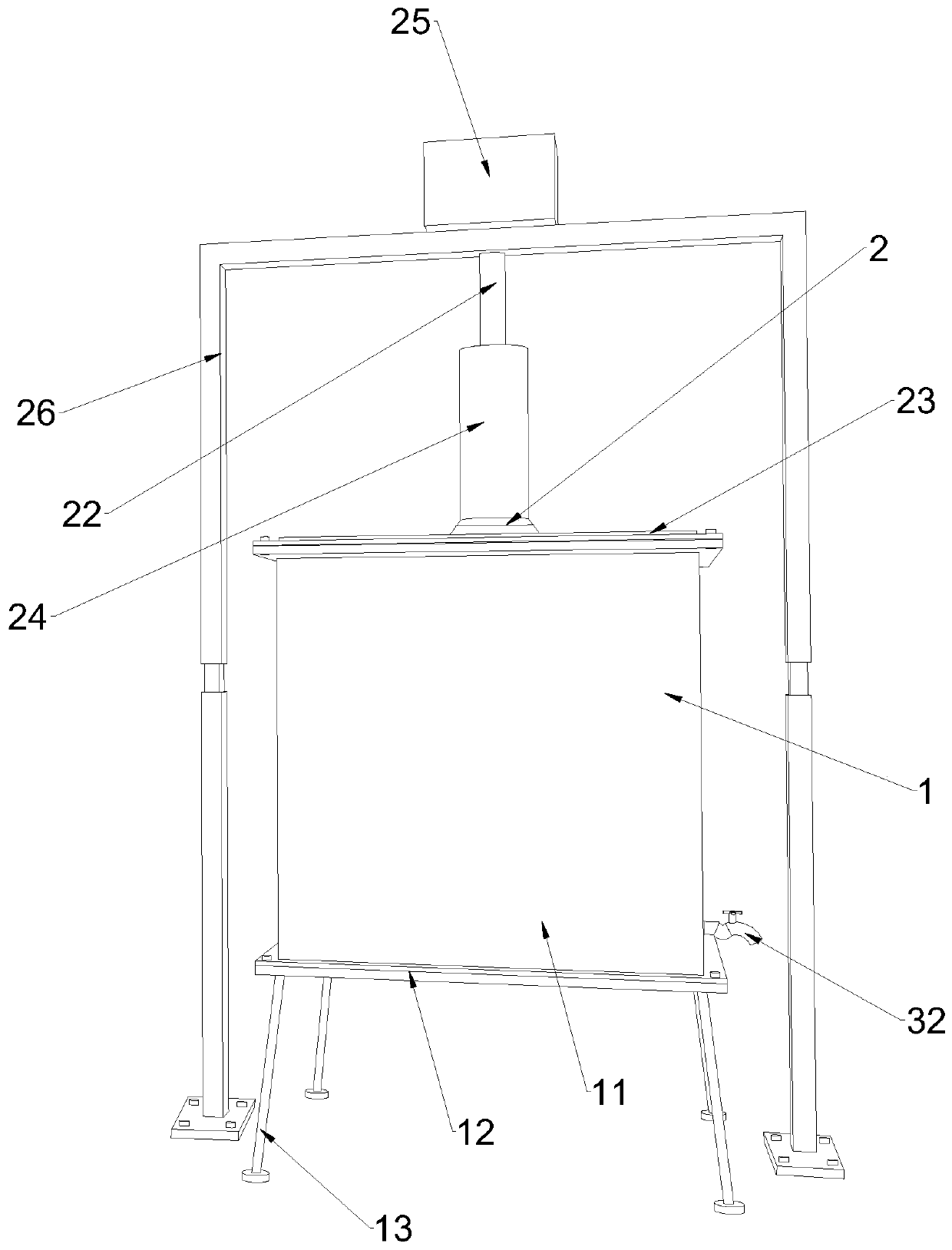

[0036] This embodiment discloses a simulation system for synchronous grouting of shield tunneling method, such as Figure 1-5 As shown, it includes a model device 1 and a propulsion device 2; the model device 1 is a container with an upper end opening; the propulsion device 2 includes a pressurized piston 21, and the pressurized piston 21 is matched with the model device 1; The pressurizing piston 21 and the model device 1 jointly form a closed space for containing the mixed slurry of the experimental soil mass and the synchronous slurry.

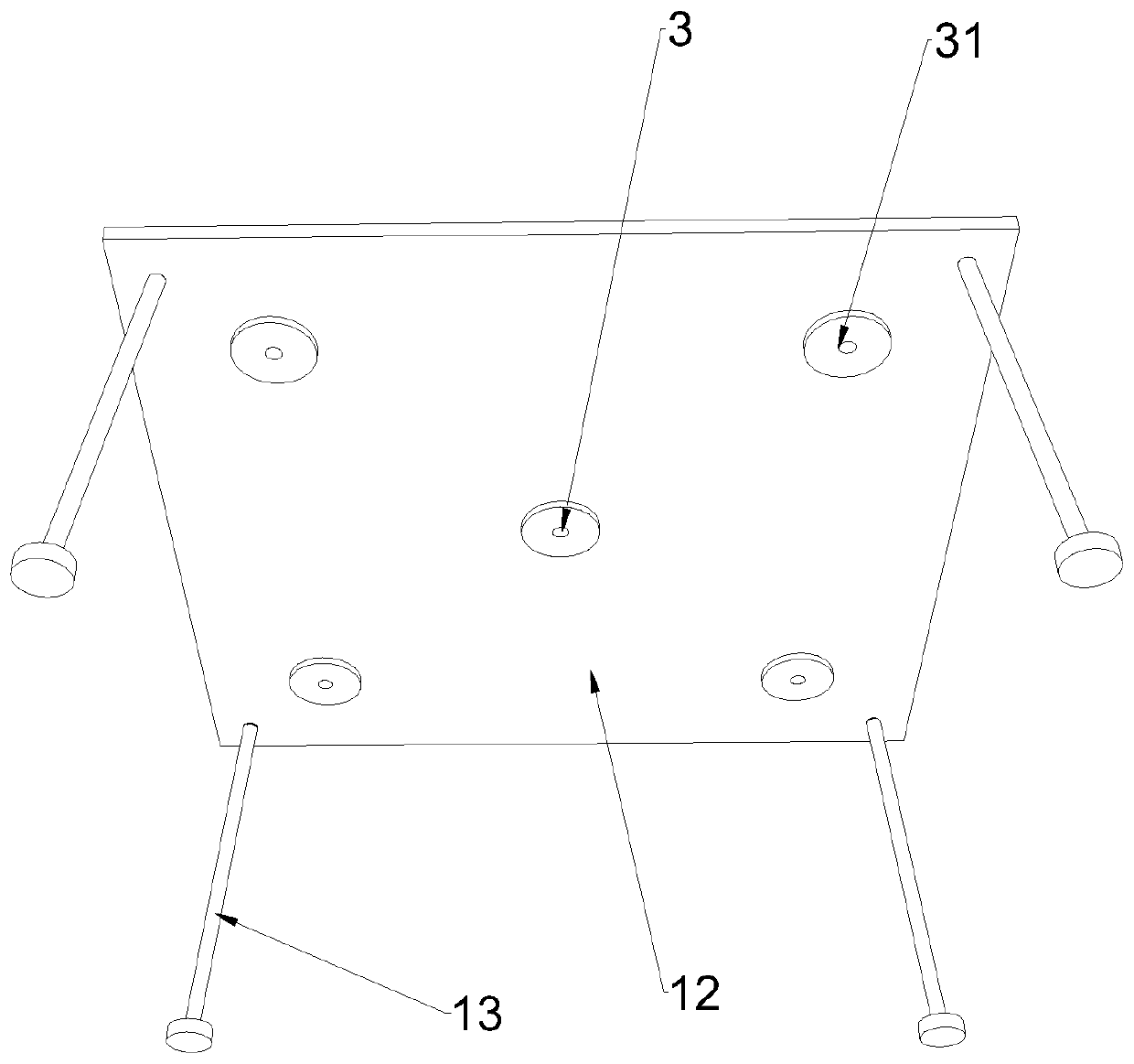

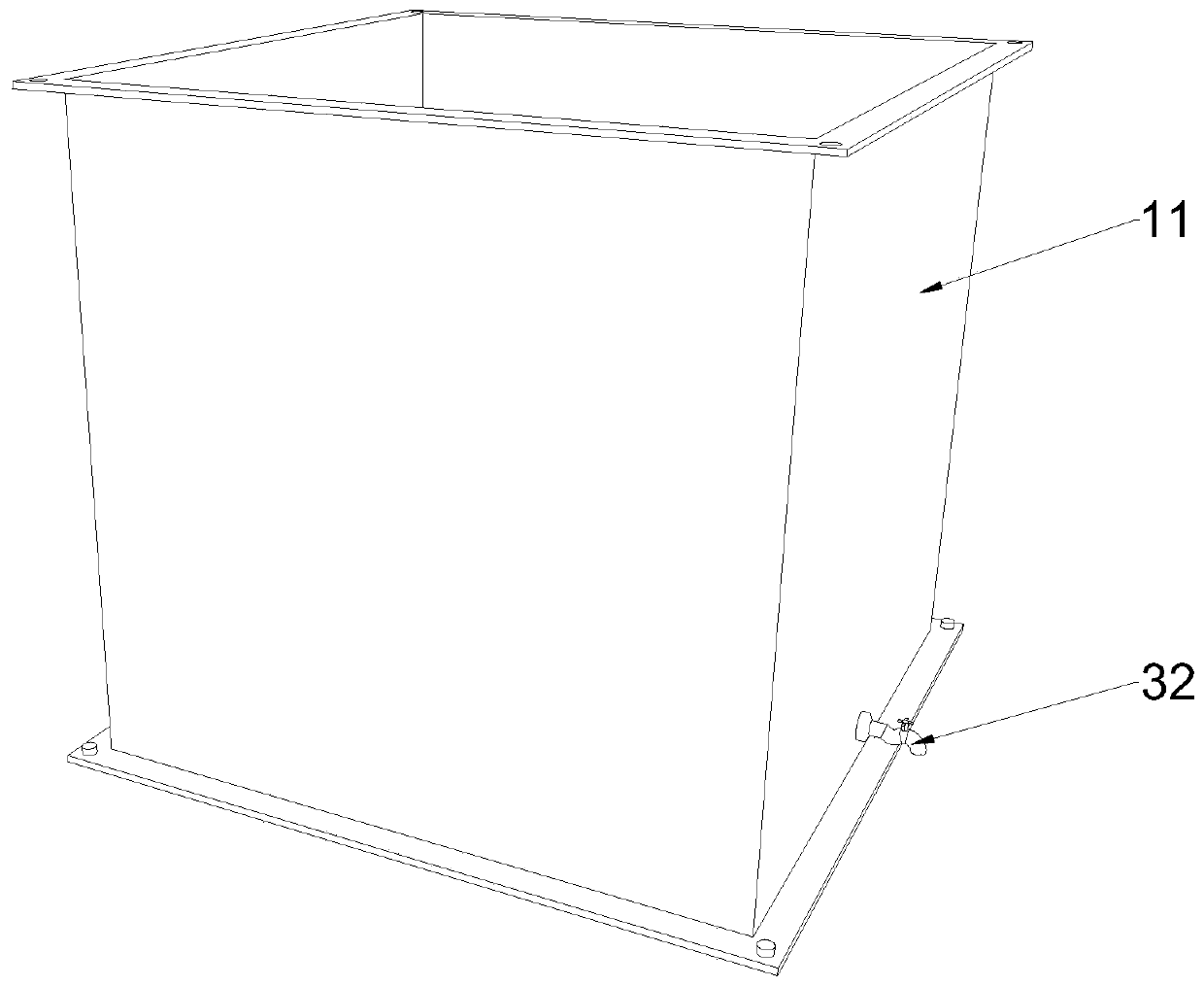

[0037] Specifically, such as Figure 1-5 As shown, the model device 1 includes a sample tube 11 and a bottom plate 12, the sample tube 11 is a container with upper and lower ends open, the bottom plate 12 closes the lower end opening of the sample tube 11, and the bottom plate 12 is detachably connected to the lower end of the sample tube 11 . Base plate 12 is made of steel, and is disassembled and installed through the screw holes at fou...

Embodiment 2

[0060] This embodiment builds on the basis of embodiment 1, such as Image 6 , 7 As shown, the model device 1 also includes an embedded cylinder 14, the embedded cylinder 14 is detachably embedded in the inside of the sample cylinder 11 of the embodiment 1, and the inner space of the embedded cylinder 14 is a cylinder body shape. The pressure piston 21 of Embodiment 1 is also modified accordingly, and changed into a disc shape 27, which together form a closed container with a cylindrical space. The embedded cylinder 14 is made according to the standard size and is made of stainless steel; a water analysis hole needs to be reserved at the position of the water analysis valve so that the cylindrical sample can analyze water smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com