Through-wall porcelain bushing wiring conduit

A technology of wiring tubes and porcelain sleeves, which is applied in the direction of electrical components, etc., can solve the problems that the terminals or joints of cables are difficult to pass through, affect the efficiency of cable laying, and affect the firmness, so as to achieve high laying efficiency and stability The effect of laying and avoiding mutual extrusion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

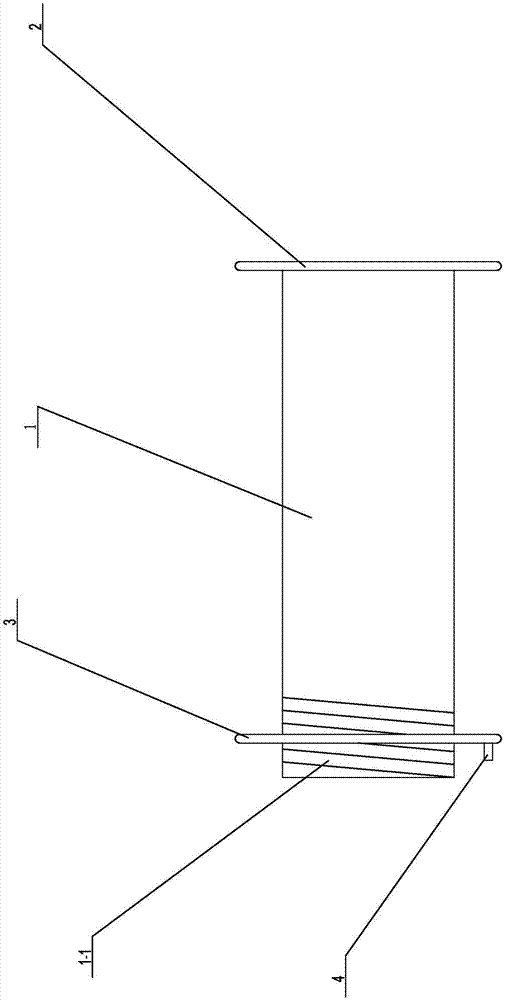

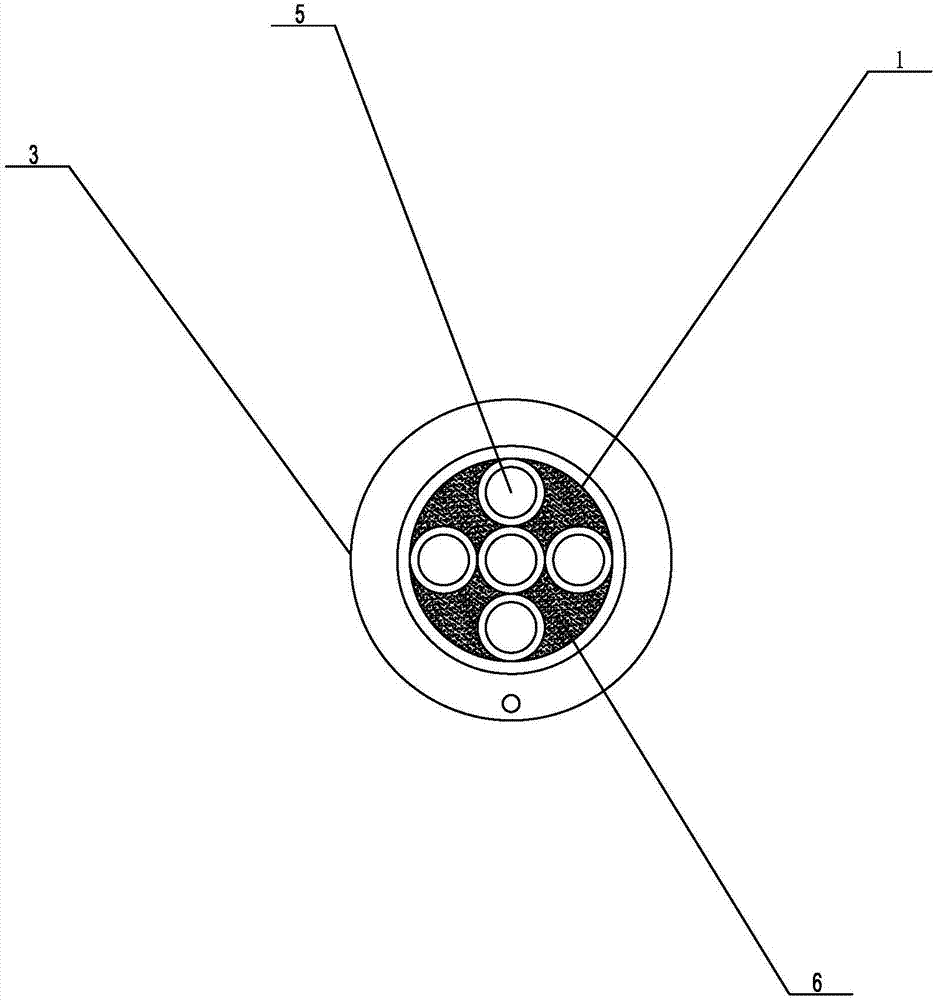

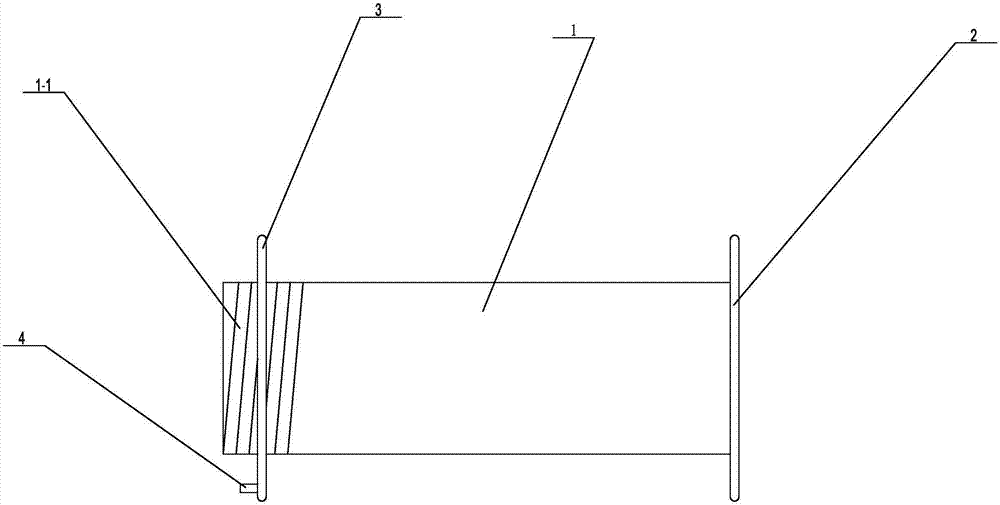

[0017] Such as figure 1 As shown, a specific embodiment of the present invention is proposed. The wall-mounted porcelain-sleeved wiring conduit includes a hollow circular sleeve 1. The diameter and length of the circular sleeve 1 should be set in combination with the size of the hole opened in the wall and the thickness of the wall. , one end of the circular sleeve 1 is provided with a fixed annular end plate 2 matched with it, and the other end of the circular sleeve 1 is set as a threaded end 1-1, and the length of the broken thread should be combined with the actual If the situation is set reasonably, and the thickness of the wall is not much different, the length of the threaded end 1-1 can be set shorter, and the threaded end 1-1 is provided with a movable annular end plate 3 that can move along its surface, and the movable annular The end plate 3 is provided with a rocker 4 that makes it move linearly on the threaded end 1-1; the circular sleeve 1 is provided with a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com