Device for optical driver component assembly

A technology of optical drives and components, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor quality of optical drive components, difficult operation, laborious operation process, etc., to avoid poor quality, simple operation, easy operation The effect is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

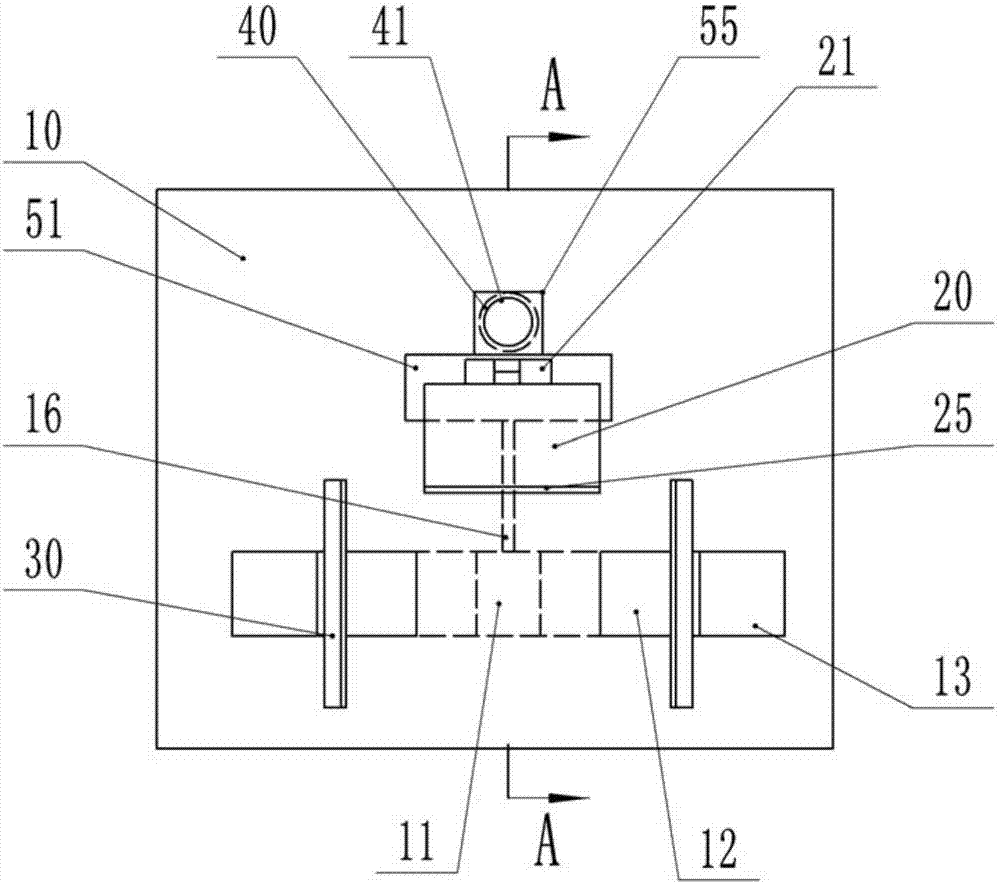

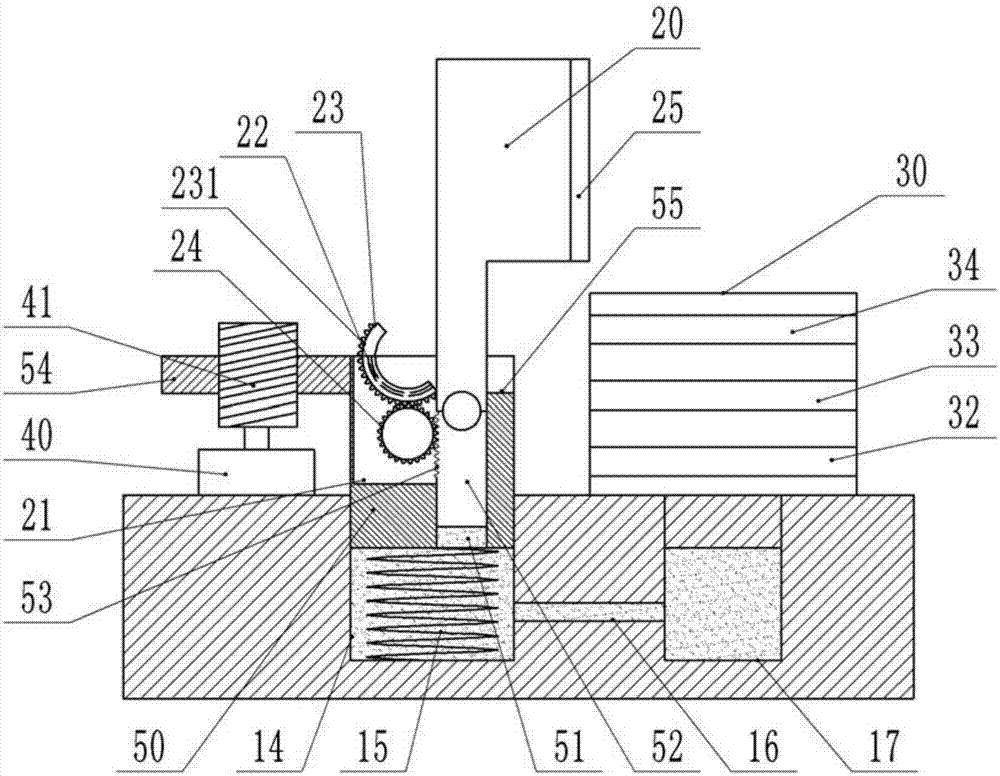

[0020] The reference signs in the drawings of the description include: workbench 10, cavity 11, slider 12, slide cavity 13, column cavity 14, supporting elastic member 15, cavity 16, pressure block 20, concave cavity 21, ring groove 22 , ring block 23, ring gear 231, gear 24, rubber pad 25, clamping frame 30, frame clip 31, optical drive clip 32, floppy drive clip 33, stepper motor 40, threaded rod 41, column block 50, vertical cavity 51, Vertical block 52, rack 53, horizontal block 54, groove 55.

[0021] like figure 1 , figure 2 As shown, the device for assembling the optical drive assembly includes a workbench 10. A cavity 11 is arranged inside the workbench 10. Two ends of the cavity 11 are provided with sliding chambers 13 with openings on the surface of the workbench 10. Inside the two sliding chambers 13 Sliding blocks 12 are respectively arranged in airtight a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com