Bottom die single linkage or dual linkage device

A dual-linkage, bottom-mold technology, applied to household components, household appliances, and other household appliances, can solve problems such as slow speed, air pollution, and high cost, and achieve improved operating speed and stability, reduced pollution, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

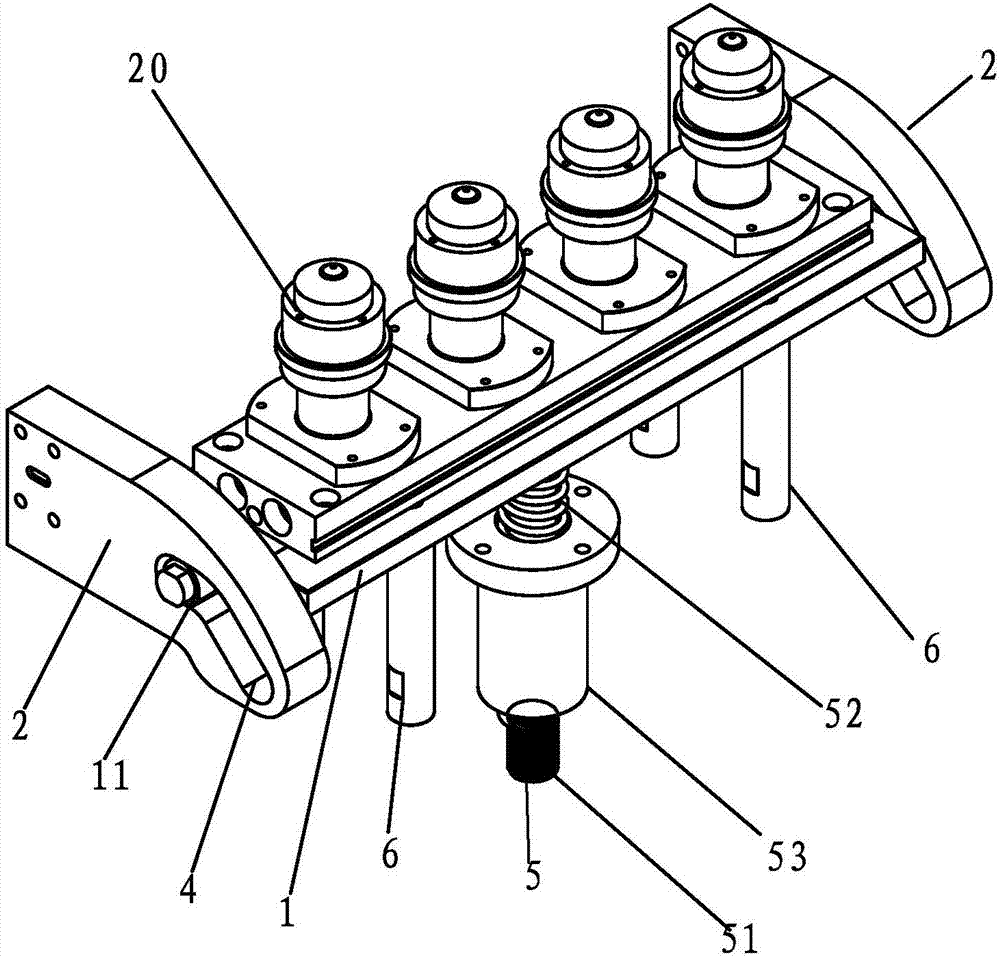

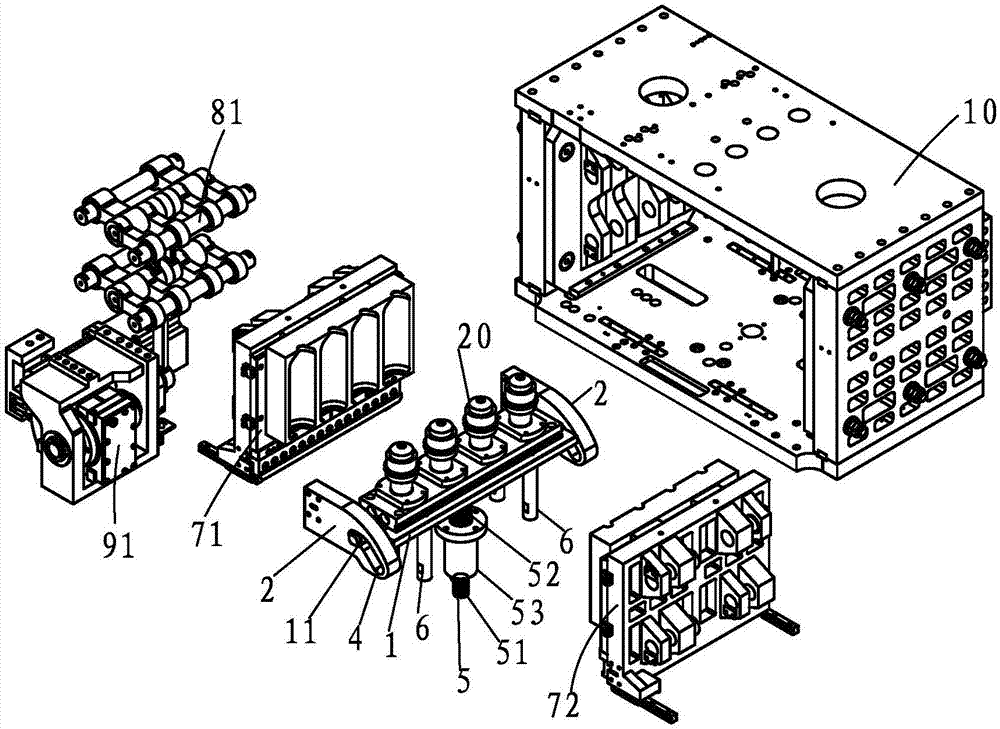

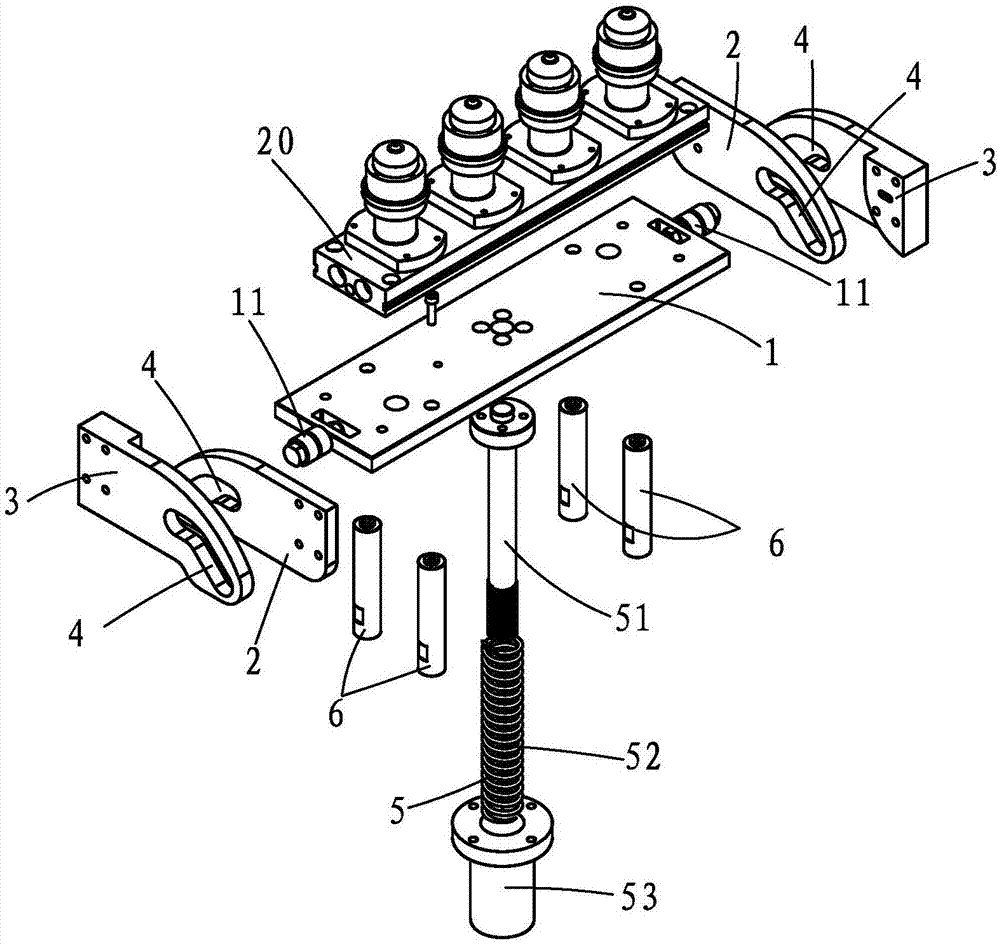

[0027] see Figure 1-2 As shown, a bottom mold single linkage device of the present invention includes a bottom mold receiving plate 1 and two first cam plates 2;

[0028] The bottom mold receiving plate 1 is used to erect the bottom mold assembly 20, and the center positions of the left and right ends of the bottom mold receiving plate 1 are respectively symmetrically provided with a cam follower 11;

[0029] The two first cam plates 2 are arranged symmetrically, and any one of the first cam plates 2 is provided with a curved track 4 for realizing the bottom mold assembly 20 to reciprocate up and down; the cam followers 11 at the left and right ends are respectively The reciprocating sliding sleeve is set in the curved track 4 of the first cam plate 2 .

[0030] Preferably, four balance columns 6 are also included, and the four balance columns 6 are respectively connected to the bottom of the bottom mold receiving plate 1 and arranged symmetrically.

[0031] Preferably, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com