Injection-molding tailgate of vehicle and vehicle

A technology for tailgates and vehicles, which is applied to vehicle parts, doors, upper structures, etc. It can solve the problems of large shape restrictions, heavy weight, surface warping appearance, etc., and achieve the goals of reducing surface bright marks, excellent surface quality, and simplifying the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

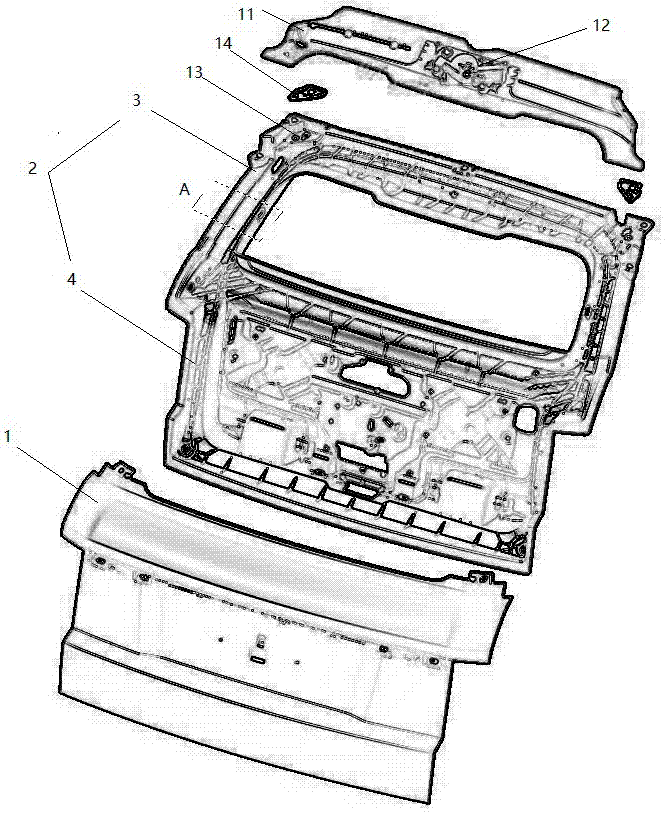

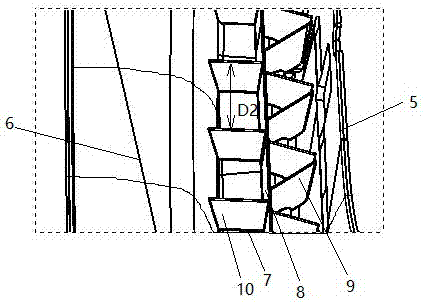

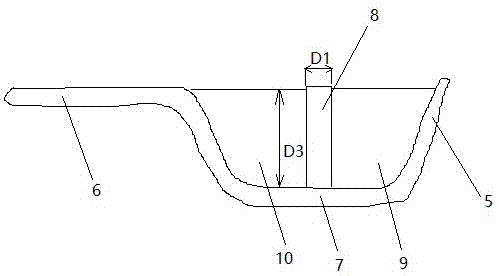

[0018] Please combine Figure 1 to Figure 3 As shown, the injection-molded tailgate of the vehicle involved in this embodiment is the tailgate of a hatchback vehicle. In addition to the rear windshield, the rear wiper needs to be installed on the tailgate. The injection molded tailgate mainly includes an outer trim panel 1 and an inner panel 2. The outer trim panel 1 and the inner panel 2 are injection molded parts. The inner panel 2 plays a similar role to the metal structure skeleton in the prior art, but the material and manufacturing process are completely different. .

[0019] The inner panel 2 includes a rear windshield frame 3 and a door panel 4 . Although the inner panel 2 is distinguished here, it should be understood that this distinction is for the convenience of describing different positions. The body of the inner pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com