Connecting structure of power battery pack frame and vehicle body mounting beam of new energy vehicle

A technology for power battery packs and new energy vehicles, which is applied in the direction of power devices, electric power devices, and substructures, and can solve problems such as easy pulling out from the body, reliability, and hidden safety hazards, so as to optimize the structural form and prevent safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

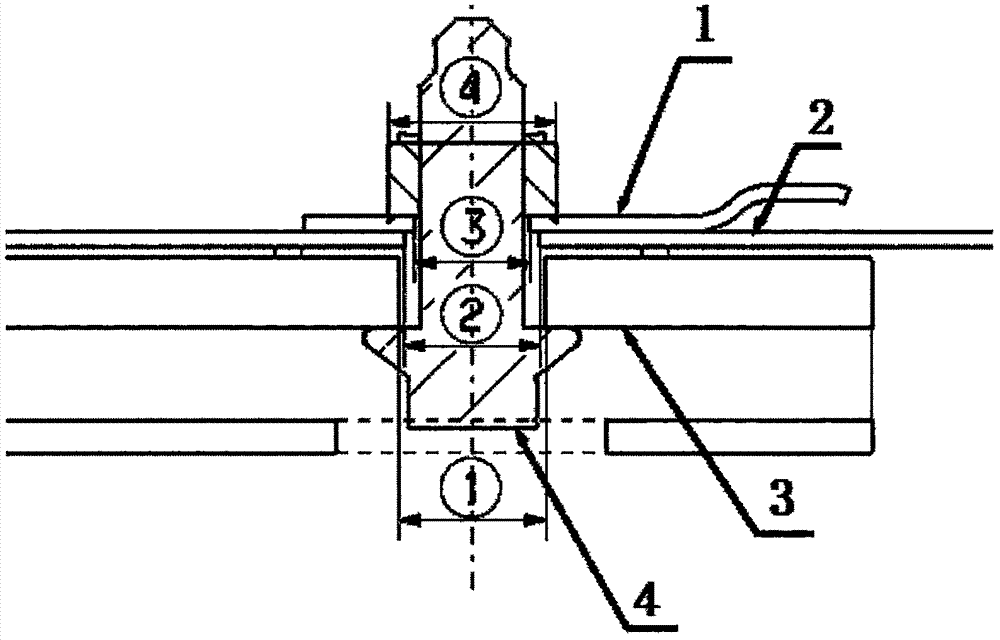

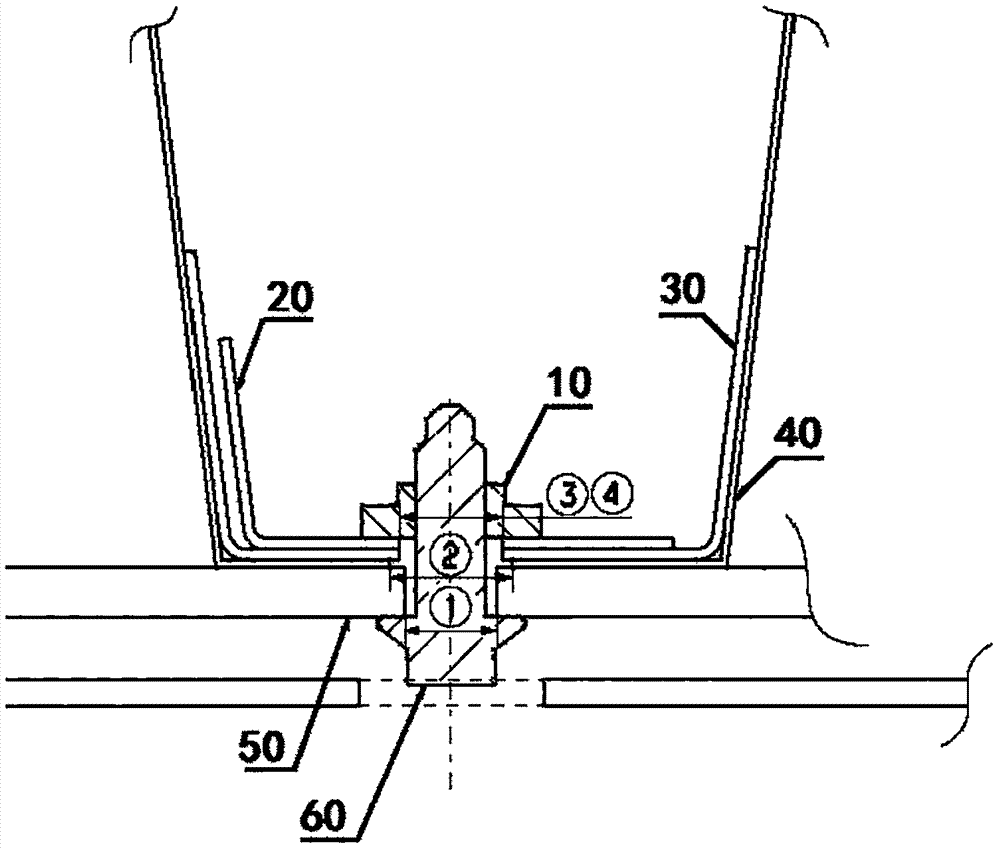

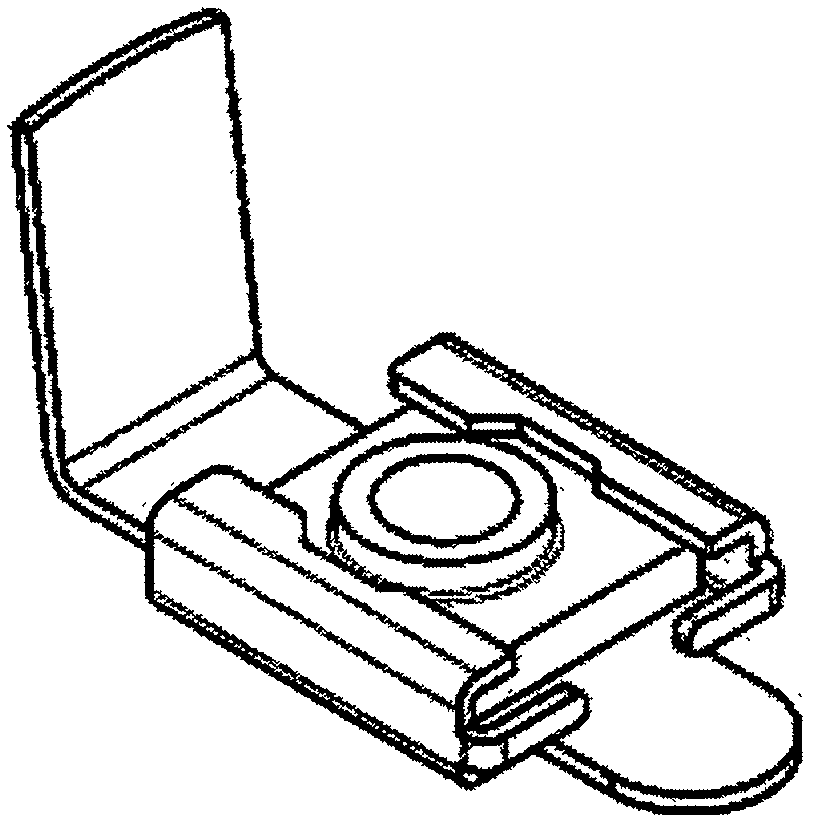

[0021] Such as Figure 2-3 As shown, the connection structure between the new energy vehicle power battery pack frame and the vehicle body mounting beam in this embodiment includes the power battery pack frame 50, the vehicle body mounting beam 40, the mounting reinforcement plate 30, the nut box 20, the nut plate 10 and the M10 bolt 60 , the M10 bolts 60 sequentially pass through the openings of the power battery pack frame 50 ( figure 2 ①, the opening of the frame installation point of the power pool package is a round hole with a diameter Ф of 14 mm), the opening of the body mounting beam 40 ( figure 2 ②, the opening of the vehicle body installation beam is a round hole, the diameter Ф is 17mm), the opening for installing the reinforcing plate 30 ( figure 2 ③, the opening of the mounting reinforcement plate is a long round hole, the specification is Ф is 12.5mm×14.5mm), the opening of the nut box 20 ( figure 2 ④, the opening of the mounting reinforcement plate is an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com