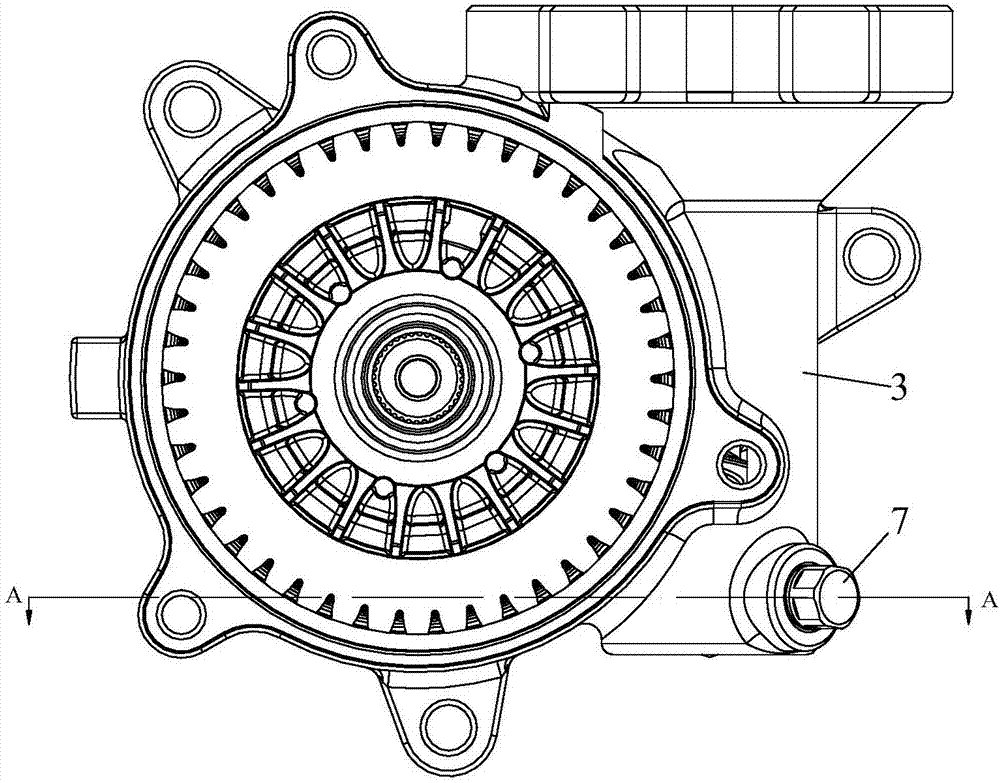

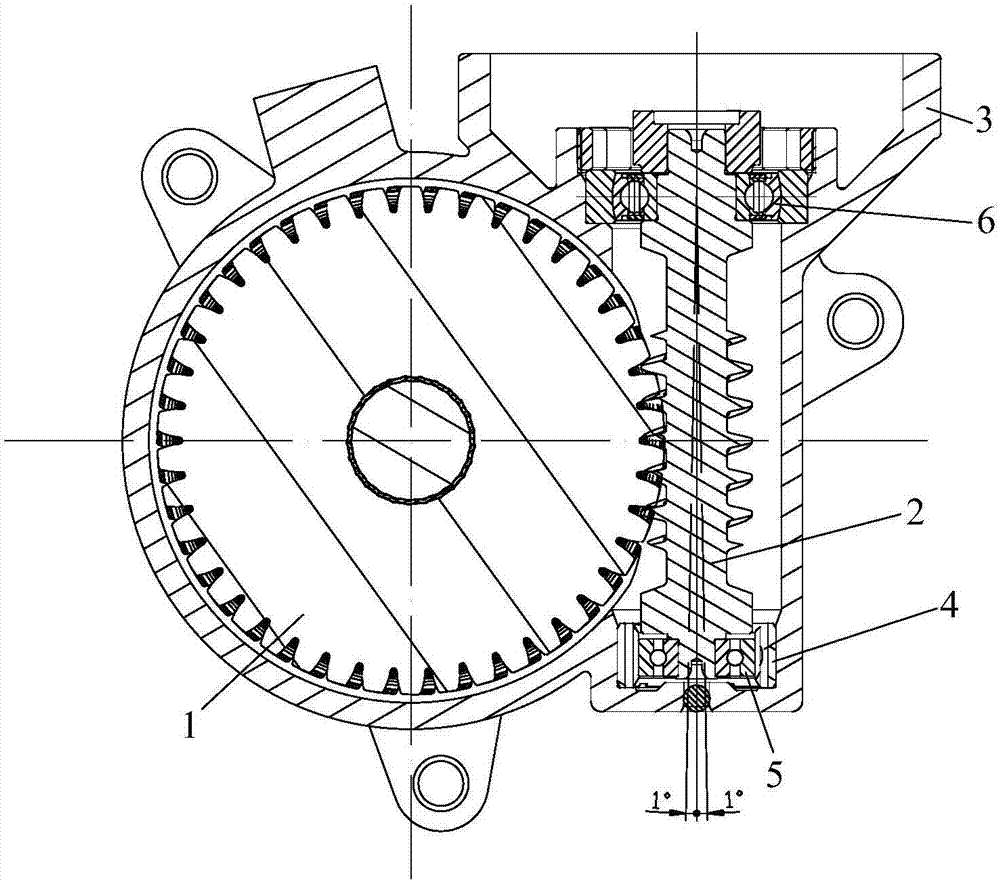

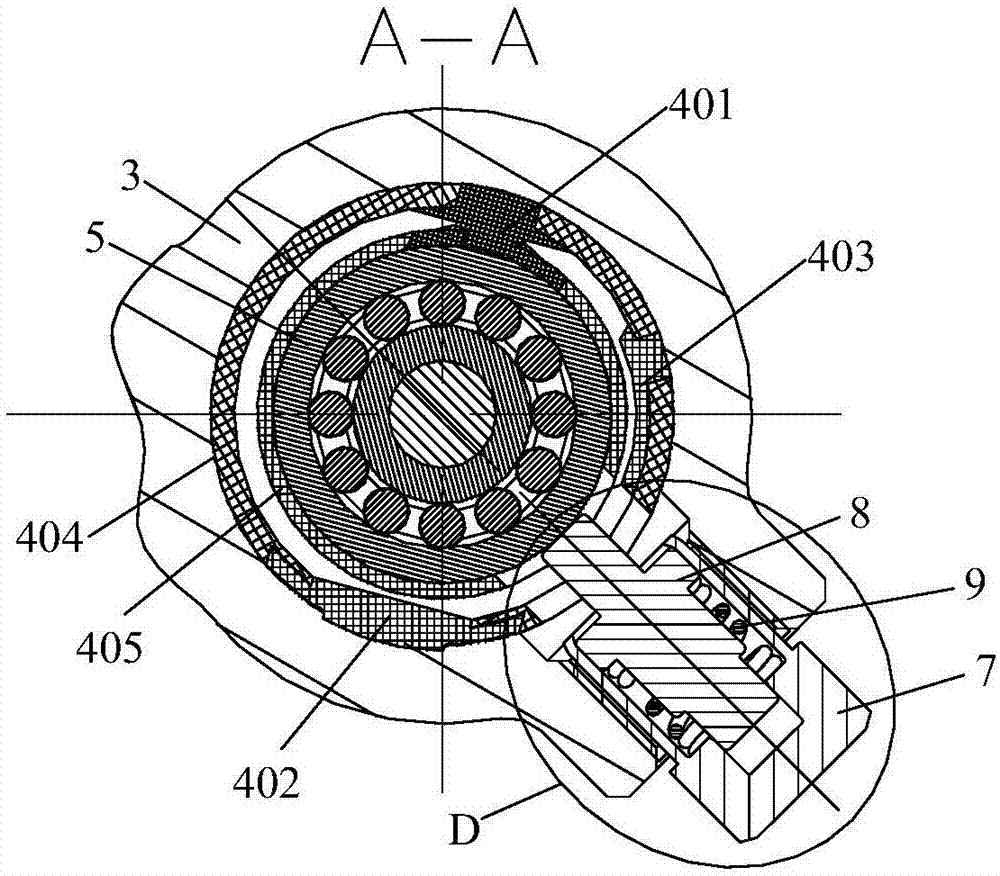

Backlash compensation mechanism applicable to reduction mechanism of electric power steering system

A technology of electric power steering and deceleration mechanism, which is applied in the direction of electric steering mechanism, power steering mechanism, steering mechanism, etc. It can solve the problems of affecting driving comfort, worm wheel size change, worm wheel expansion or contraction, etc., to avoid mechanical abnormal noise and The effects of steering destabilization, improving adaptability, and avoiding stuck problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0031] The deceleration mechanism of the electric power steering system in the prior art has errors in the machining dimensions of the worm gear and worm, and the machining dimensions of the reduction box have errors. The worm gear and worm have wear phenomena, thermal expansion and cold contraction during long-term use, resulting in The meshing center distance of the worm gear and worm and the center distance of the reduction box change, resulting in gaps or abnormal wear on the tooth surface of the worm gear, resulting in an increase in the meshing gap between the worm gear and the worm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com