Railway auxiliary beam rapid transporting and erecting trailer

A fast transportation and trailer technology, applied in the transportation of passenger cars, railway car body parts, bridge construction, etc., can solve the problems of high cost, low efficiency, and difficulty in entering the field for beams and large construction equipment, so as to save construction costs and realize The effects of automation, significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

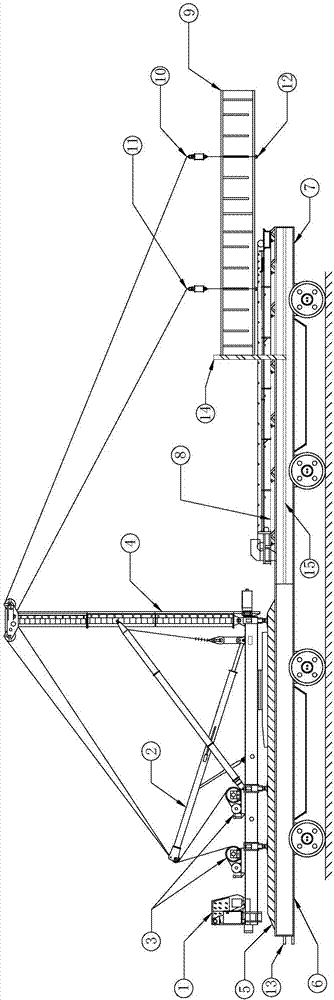

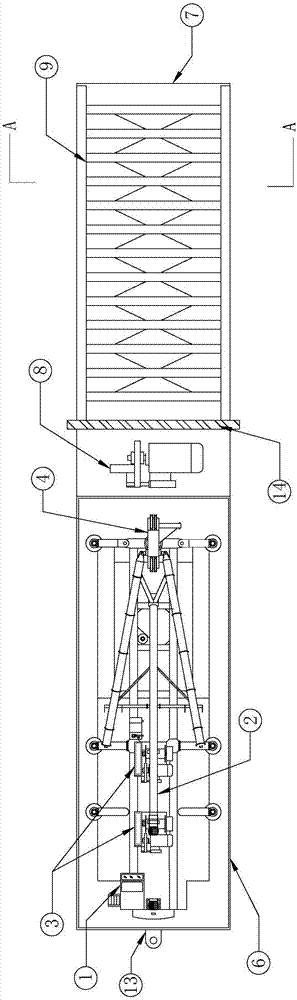

[0026] The railway convenient beam fast transportation erection trailer of present embodiment is as Figure 1-Figure 3 As shown, it includes: a suspension part trailer 6, a transmission part trailer 7, a suspension part 16, a transmission part 17 and a prefabricated beam 9. Wherein, the control part 1, the hanging part 2, the power traction part 3 and the reaction force frame 4 jointly form the suspension part 16; 17 are placed on the suspension part trailer 6 and the transmission part trailer 7 respectively.

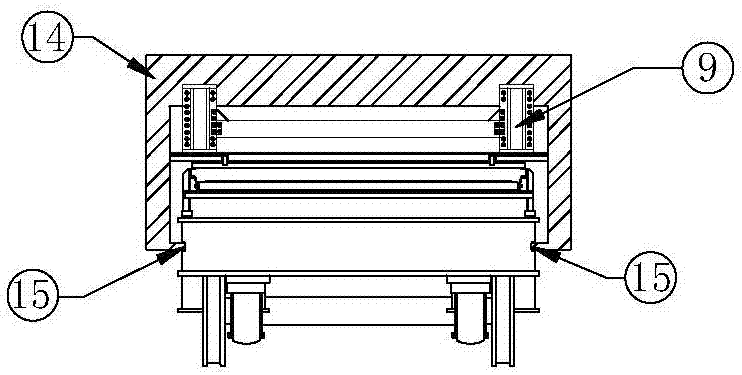

[0027] Such as Figure 4-Figure 10 Shown, thicken 10-15 centimeter suspension part trailer 6 base plates to form counterweight part 5 to increase the overall stability of the trailer system when prefabricated beam 9 is suspended. The transfer part trailer 7 is additionally provided with a reaction force baffle chute 15 so that the reaction force baffle 14 slides. Add welded 1 / 4 and 3 / 4 points at the bottom of prefabricated 9 bottom slings 12 to facilitate sling insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com