Birotor oppositely-rotating stamping gas compressor

A compressor and double-rotor technology, which is applied in the field of compressors and double-rotor counter-rotating ram compressors, can solve the problems of high pressure specific time stages, minimum flow limitation, and uncommon compressors, etc., and reduce the number of parts and Effect of swirl loss, wide pressure ratio working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

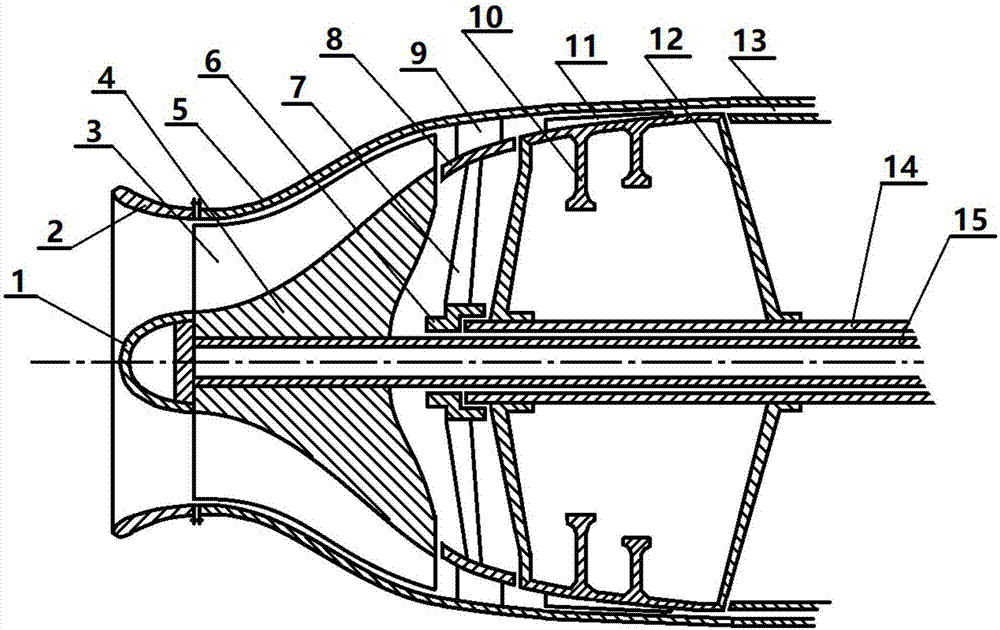

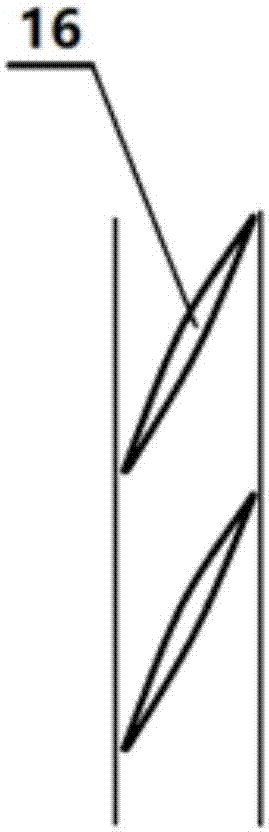

[0031] exist figure 1 , figure 2 In the shown structure, a dual-rotor counter-rotating ram compressor designed by the present invention is composed of two parts: a rotor and a stator; the rotor includes a front rotor and a rear rotor arranged in sequence, each rotor includes an impeller and a shaft, and The rotor is designed as a diagonal flow impeller, including a fairing 1, a front rotor blade 3, a front rotor disc 4, and a front rotor shaft 15. The rear rotor is an axial-flow impeller, including a rear rotor disc 10, a rear rotor blade 11, a rear rotor shaft 14, and a journal 12. The rear rotor blade 11 is designed as a shuttle-shaped straight blade 16 with pointed ends and elongated shape.

[0032] The stator includes intake pipe 2, casing 5, rectifying vane 9, middle inner cylinder 8, rib plate 7, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com